Battery thermal management system for hybrid power vehicle model

A battery thermal management and hybrid technology, applied in electric vehicles, secondary batteries, battery/fuel cell control devices, etc., can solve problems such as longer working hours, increased vehicle costs, poor control stability, etc. The effect of short heating time, shortened flow path and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

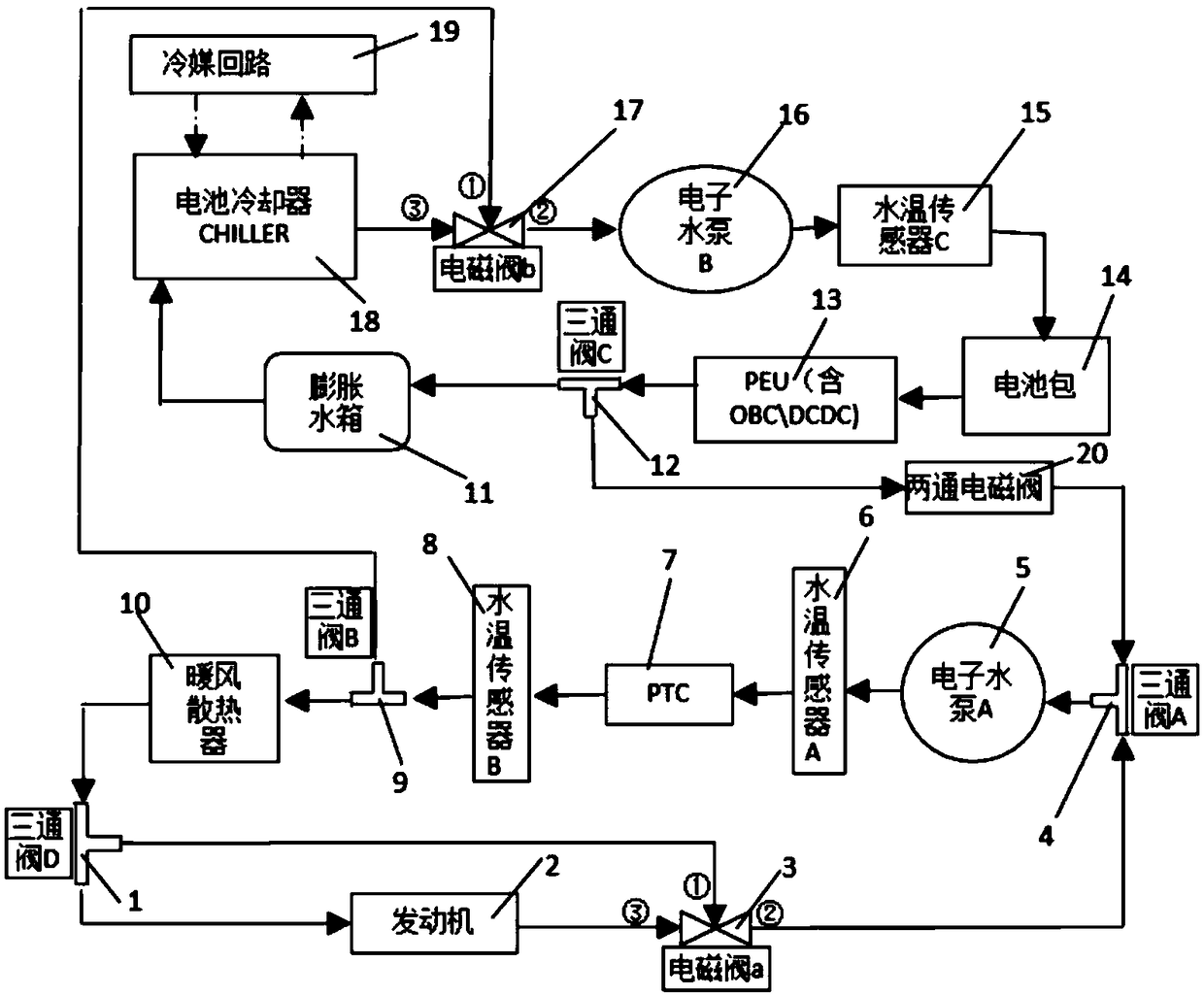

[0018] Such as figure 1 As shown, a battery thermal management system applied to hybrid vehicles includes: electric heater PTC7, electronic water pump A5, electronic water pump B16, water temperature sensor A6, water temperature sensor B8, water temperature sensor C15, battery pack 14, PEU (including OBC charger and DCDC current converter) 13, battery cooler 18, expansion tank 11, three-way valve A4, three-way valve B9, three-way valve C12, three-way valve D1, three-way solenoid valve a3, three-way solenoid valve b17, two-way solenoid valve 20, warm air radiator 10 integrated in the air conditioning box, engine water jacket 2, refrigerant circuit 19 connected with battery cooler 18 and water pipes connecting various components.

[0019] The outlet of the electronic water pump A5 is connected to the water temperature sensor A6, the electric heater PTC7, the water temperature sensor B8, and the inlet of the three-way valve B9 in sequence through the water pipe, and one of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com