Solid organic fertilizer decomposing speed increasing method

A solid organic matter and organic fertilizer technology, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of biological organic parts, can solve problems that affect the quality and scope of application of organic fertilizers, low fertilizer maturity, and long fermentation cycles. The effect of decomposing speed, rich nutrition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

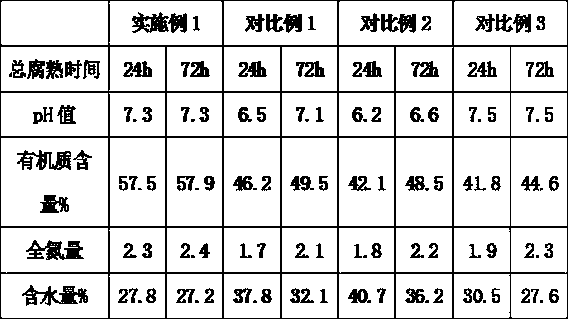

Examples

Embodiment 1

[0021] A kind of method that can promote solid organic fertilizer to decompose speed, comprises the following steps:

[0022] A. Crush the solid organic raw material and transfer it to a fermenter, add microbial mixed bacterial agent 1, stir evenly, and carry out aerobic fermentation of the solid organic raw material in a warehouse-type fermenter, control the fermentation temperature at 58 ° C, after 4.5 hours humidify;

[0023] B. Spray water evenly on the solid organic raw material and heat it to control the moisture content of the solid fermented product to 48%. When the temperature of the solid organic raw material reaches 65°C, stop heating, add distiller's grains and microbial mixed bacterial agent 2, and stir evenly ;

[0024] C. Carry out oxygenation through the ventilation of the aeration fan. After 4 hours of fermentation, add microbial mixed bacterial agent 3, stir evenly, and then feed nitrogen to carry out anaerobic fermentation. After 13.5 hours, the fermentatio...

Embodiment 2

[0034] A kind of method that can promote solid organic fertilizer to decompose speed, comprises the following steps:

[0035] A. Crush the solid organic raw material and transfer it to a fermenter, add microbial mixed bacterial agent 1, stir evenly, carry out aerobic fermentation of the solid organic raw material in a warehouse-type fermenter, control the fermentation temperature at 50°C, and carry out after 6 hours Humidification;

[0036] B. Spray water evenly on the solid organic raw material and heat it to control the moisture content of the solid fermented product to 45%. When the temperature of the solid organic raw material reaches 65°C, stop heating, add distiller's grains and microbial mixed bacterial agent 2, and stir evenly ;

[0037] C. Carry out oxygenation through the ventilation of the aeration fan. After 5 hours of fermentation, add microbial mixed bacterial agent 3, stir evenly, and then feed nitrogen for anaerobic fermentation. After 12 hours, the fermentati...

Embodiment 3

[0047] A kind of method that can promote solid organic fertilizer to decompose speed, comprises the following steps:

[0048] A. Crush the solid organic raw material and transfer it to a fermenter, add microbial mixed bacterial agent 1, stir evenly, carry out aerobic fermentation of the solid organic raw material in a warehouse-type fermenter, control the fermentation temperature at 65°C, and carry out after 4 hours Humidification;

[0049] B. Spray water evenly on the solid organic raw material and heat it to control the moisture content of the solid fermented product to 50%. When the temperature of the solid organic raw material reaches 65°C, stop heating, add distiller's grains and microbial mixed bacterial agent 2, and stir evenly ;

[0050]C. Carry out oxygenation through the ventilation of the aeration fan. After 3 hours of fermentation, add microbial mixed bacterial agent 3, stir evenly, and then feed nitrogen for anaerobic fermentation. After 14 hours, the fermentatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com