Modified asphalt composition and preparation method thereof

A technology of modified asphalt and composition, which is applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of limited, single modification, and no research on the synergistic effect of modifiers, so as to avoid agglomeration, improve Road performance and the effect of preventing structural chain breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of raw material of modified asphalt composition is equipped as follows:

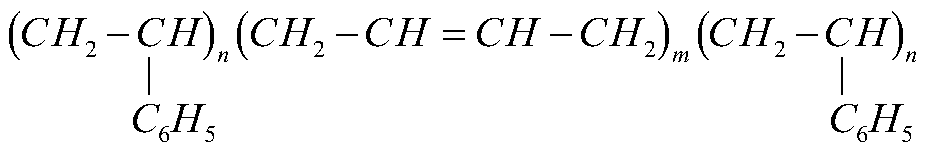

[0032] Styrene-butadiene-styrene block copolymer 4wt%;

[0033] Ethylene-vinyl acetate copolymer 0.12wt%;

[0034] Polystyrene 1wt%;

[0035] Melamine resin 1wt%;

[0036] Terpene resin 10wt%;

[0037] Transition metal oxide 4wt%;

[0038] Calcium carbonate 1wt%;

[0039] Base asphalt balance.

[0040] The preparation method of the modified asphalt composition mainly includes the following process steps: step 1, adding styrene-butadiene-styrene block copolymer into the reaction kettle for preheating and stirring, then adding transition metal oxide under stirring condition, keeping the temperature At 150°C±5°C, perform high-speed stirring for 60-250 minutes to obtain additive A; step 2, add a certain amount of base asphalt into the stirred reactor, and Under certain conditions, add additive A, and shear through a high-speed shear emulsifier for 60-120 minutes. When the viscosity of t...

Embodiment 2

[0042] A kind of raw material of modified asphalt composition is equipped as follows:

[0043] Styrene-butadiene-styrene block copolymer 2wt%;

[0044] Ethylene-vinyl acetate copolymer 0.4wt%;

[0045] Polystyrene 1wt%;

[0046] Melamine resin 2wt%;

[0047] Terpene resin 12wt%;

[0048] Transition metal oxide 5wt%;

[0049] Calcium carbonate 2wt%;

[0050] Base asphalt balance.

[0051]The preparation method of the modified asphalt composition mainly includes the following process steps: step 1, adding styrene-butadiene-styrene block copolymer into the reaction kettle for preheating and stirring, then adding transition metal oxide under stirring condition, keeping the temperature At 150°C±5°C, perform high-speed stirring for 60-250 minutes to obtain additive A; step 2, add a certain amount of base asphalt into the stirred reactor, add additive A under the condition of 175-185°C, and pass through high-speed The shearing emulsifier shears for 60-120 minutes. When the vis...

Embodiment 3

[0053] A kind of raw material of modified asphalt composition is equipped as follows:

[0054] Styrene-butadiene-styrene block copolymer 6wt%;

[0055] Ethylene-vinyl acetate copolymer 0.3wt%;

[0056] Polystyrene 3wt%;

[0057] Melamine resin 2wt%;

[0058] Terpene resin 14wt%;

[0059] Transition metal oxide 5wt%;

[0060] Calcium carbonate 1wt%;

[0061] Base asphalt balance.

[0062] The preparation method of the modified asphalt composition mainly includes the following process steps: step 1, adding styrene-butadiene-styrene block copolymer into the reaction kettle for preheating and stirring, then adding transition metal oxide under stirring condition, keeping the temperature At 150°C±5°C, perform high-speed stirring for 60-250 minutes to obtain additive A; step 2, add a certain amount of base asphalt into the stirred reactor, add additive A under the condition of 175-185°C, and pass through high-speed The shearing emulsifier shears for 60-120 minutes. When the vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com