Black printing ink, and preparation method and application thereof

A technology of black ink and carbon black, which is applied in the field of flexible circuit boards, can solve the problems of immature production technology, difficult production, and high difficulty, and achieve the effects of wide sources of production raw materials, avoiding short circuits between lines, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

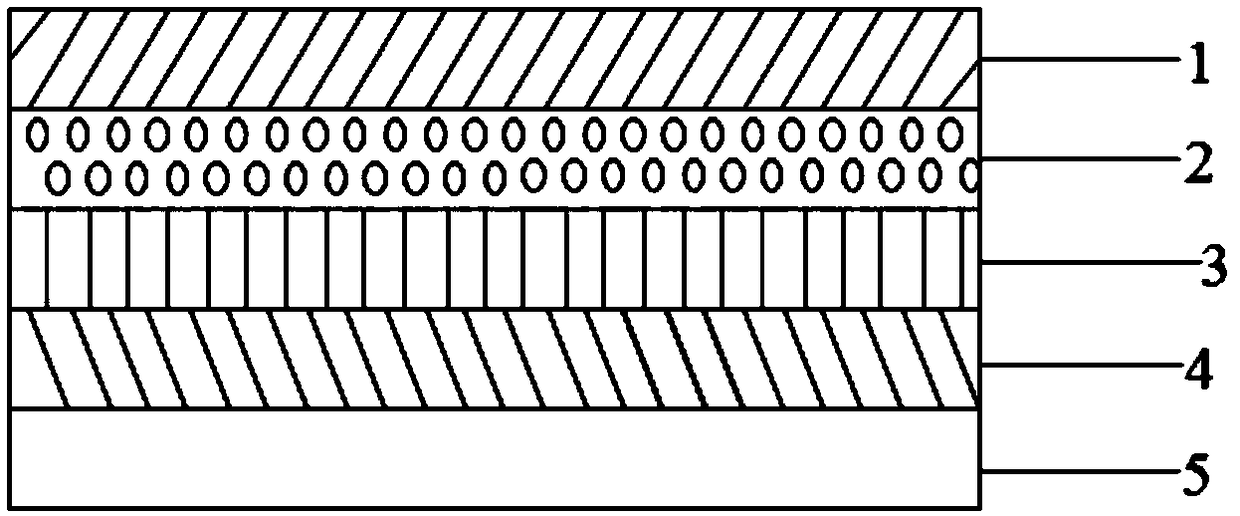

Image

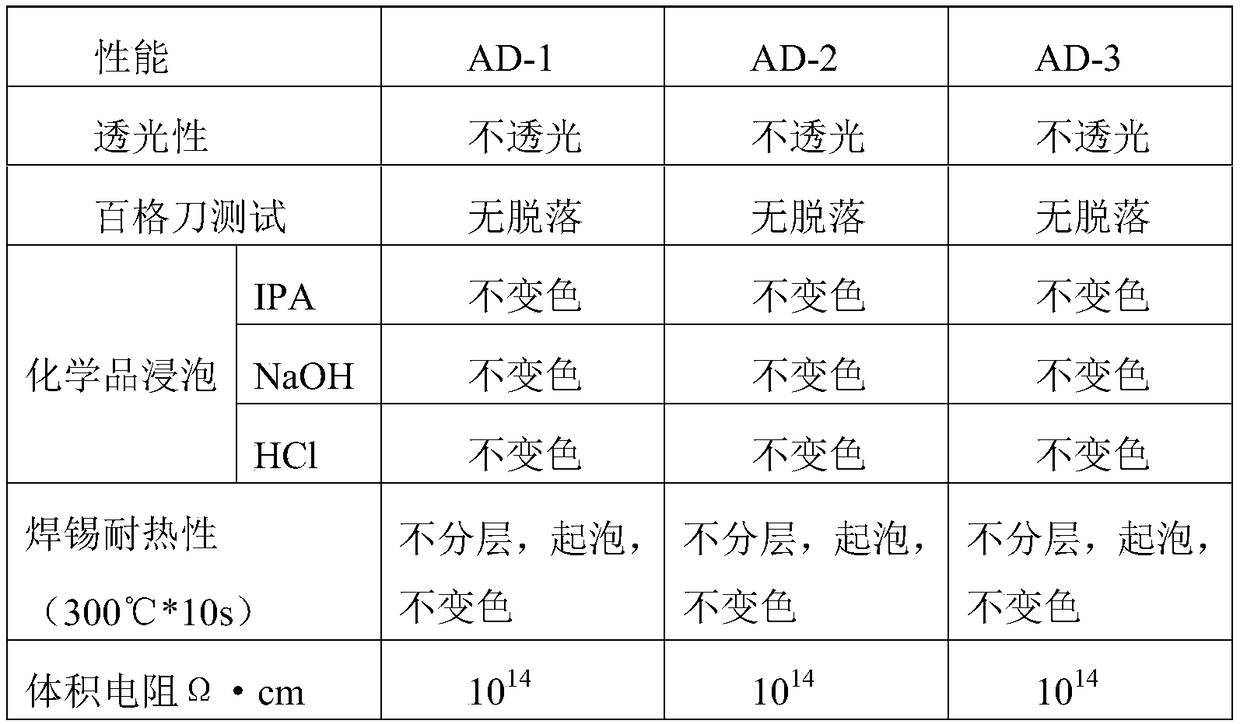

Examples

Embodiment 1

[0048] This example has prepared a kind of black ink, and number is A, and component and preparation method are:

[0049] Add ODA, 2,2-bis(4-(4-aminophenoxy)phenyl)propane, two diamines; and BPADA, BTDA anhydride into the NMP solvent according to the molar ratio of anhydride:diamine of 1:1 , wherein the solid content is 20%, fully mixed and stirred in a water bath at 5°C for 8 hours to obtain PAA acid;

[0050] Add acetic anhydride and pyridine to the PAA acid synthesized in the first step at a molar ratio of 2:1:1 to acid anhydride and dehydrate at 90°C for 7 hours to obtain soluble polyimide 1.

[0051] Add the above 32g soluble polyimide 1 solution, 3.84g Clariant OP-935, 7.72g Nagase XD-1000 resin, 8g DMAC solvent, 4.5g Mitsubishi MA-100, 0.6g talcum powder in order, Stir at high speed for 2 hr to obtain black ink A.

Embodiment 2

[0053] This example has prepared a kind of black ink, and number is B, and component and preparation method are:

[0054] Add 3,3'-DDS, 2,2-bis(4-(4-aminophenoxy)phenyl)propane, two diamines; and BPADA, PMDA anhydride into NMP solvent in a molar ratio of 1:1 , wherein the solid content is 10%, fully mixed and stirred in a water bath at 5°C for 8 hours to obtain PAA acid;

[0055] Add acetic anhydride and isoquinoline to the PAA acid synthesized in the first step at a molar ratio of 2:1:1 to acid anhydride and dehydrate at 90°C for 7 hours to obtain soluble polyimide 2.

[0056]Add the above 30g soluble polyimide 2 solution, 3.2g Clariant OP-935, 7.72g Nagase XD-1000 resin, 8g DMAc solvent, 4.3g Mitsubishi MA-100, 0.4g talcum powder in order, Stir at high speed for 2 hr to obtain black ink B.

Embodiment 3

[0058] This example prepares a kind of black ink, number is C, and component and preparation method are:

[0059] ODA, 2,2-bis(4-(4-aminophenoxy)phenyl)propane two diamines; and BPADA, BTDA acid anhydride are added to the NMP solvent in a molar ratio of 1:1, wherein the solid content 20%, fully mixed and stirred in a water bath at 5°C for 8 hours to obtain PAA acid.

[0060] Add acetic anhydride and pyridine to the PAA acid synthesized in the first step at a molar ratio of 2:1:1 to acid anhydride and dehydrate at 90°C for 7 hours to obtain soluble polyimide 3.

[0061] Add the above 32g soluble polyimide 3 solution, 4.2g Clariant OP-935, 7.72g Nagase XD-1000 resin, 8g DMAc solvent, 0.5g nigrosine, and 1.0g talcum powder in order, and stir at high speed 2hr, black ink C was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com