An anti-seismic prefabricated assembled bridge pier and its construction method

A prefabricated assembly and bridge pier technology, applied in erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of complex structure, long construction period, high cost, etc., achieve simple and efficient assembly, and prevent cracking and crushing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

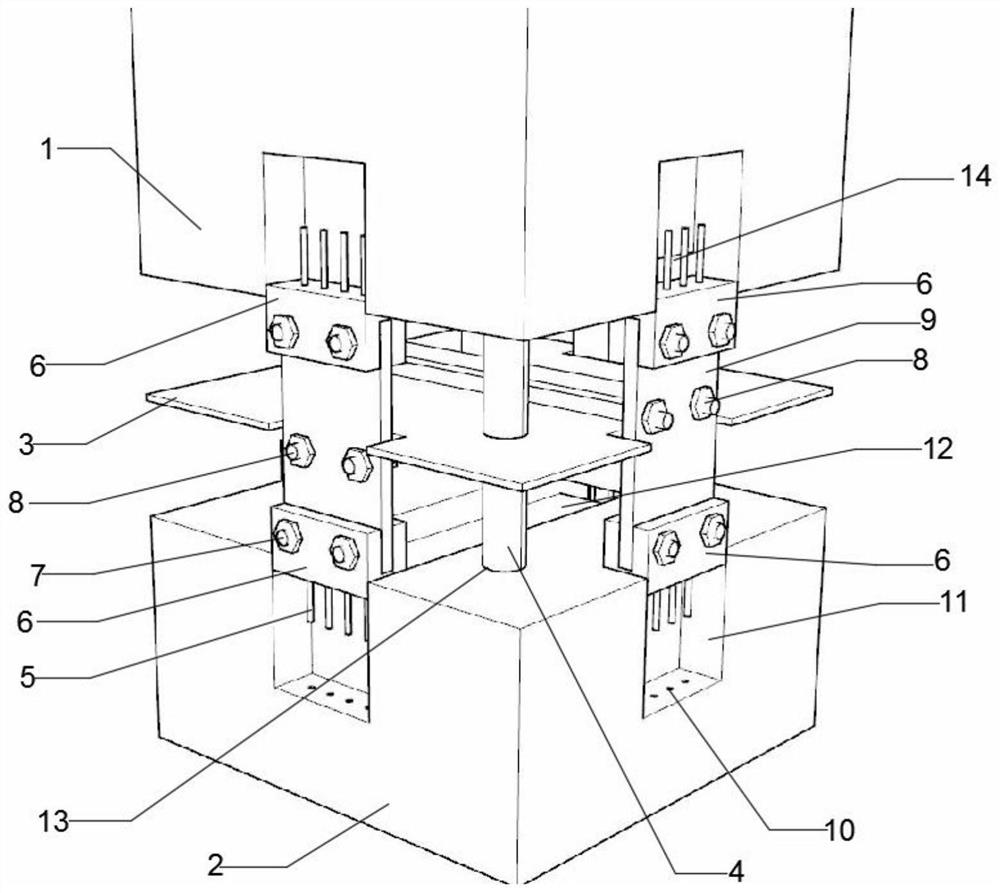

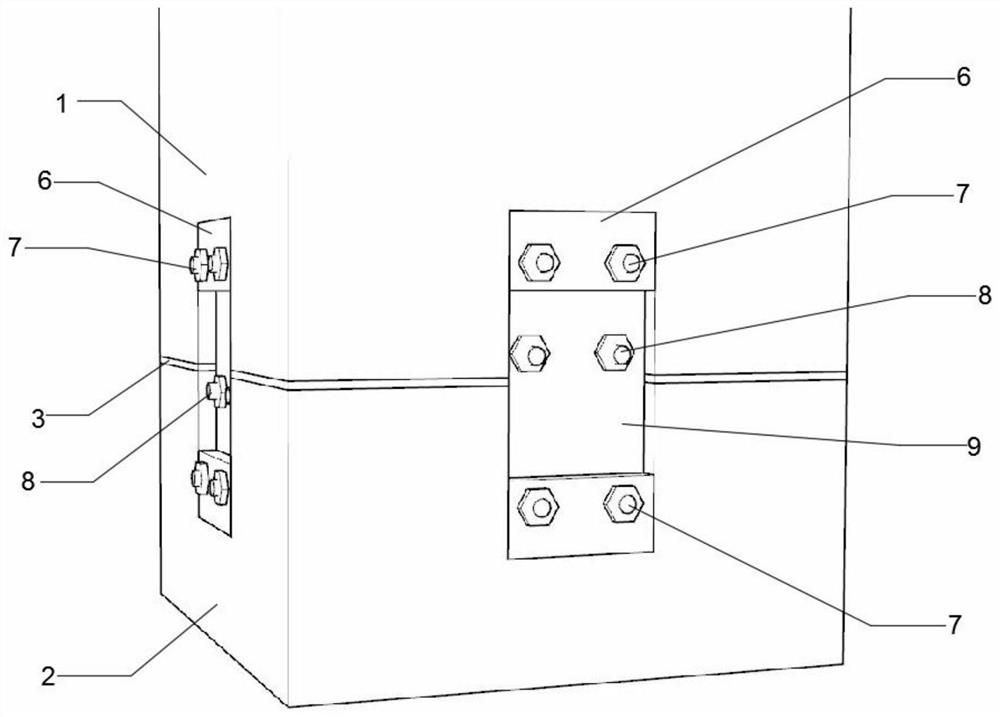

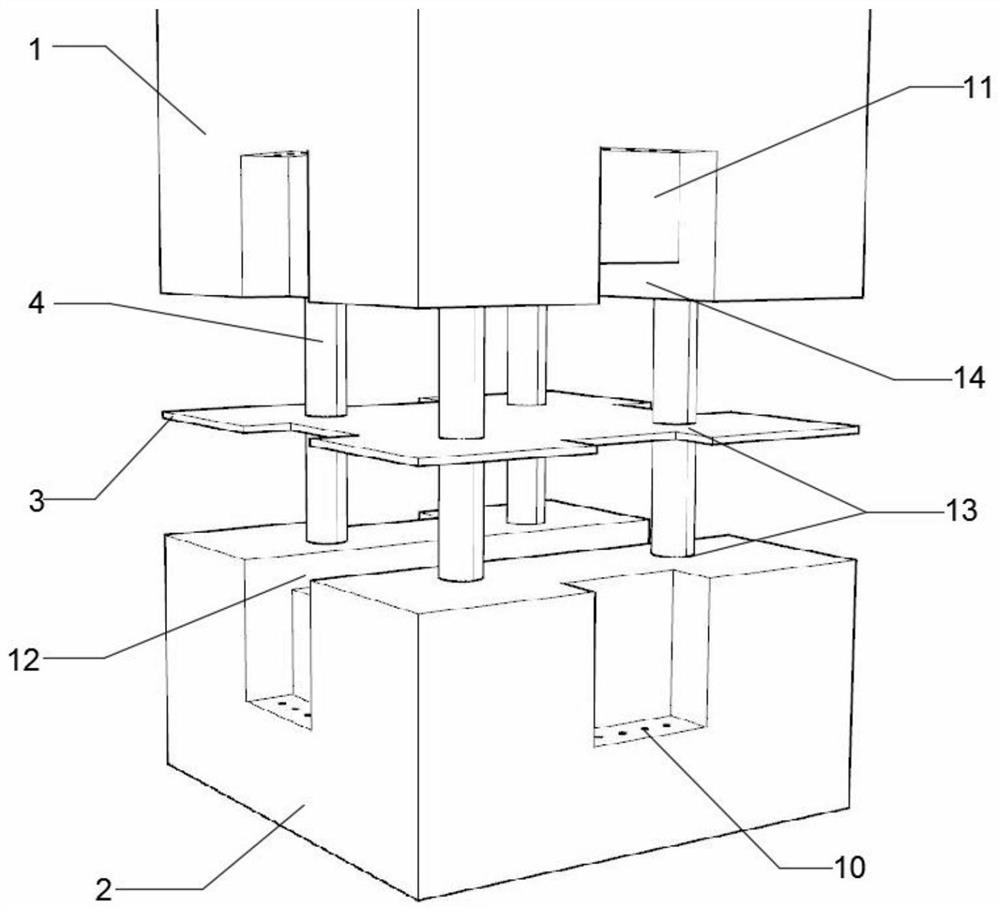

[0027] Below, the present invention will be described in further detail in conjunction with the accompanying drawings.

[0028] like Figure 1-5 As shown, this embodiment discloses an anti-seismic prefabricated assembled bridge pier, including an upper section 1 of a pier column, a lower section 2 of a pier column, a rubber elastic layer 3, a prestressed tendon 4, an energy-dissipating steel plate 9, an anchoring device and a pair of tensile Bolt 8.

[0029] The rubber elastic layer 3 is arranged between the upper section 1 of the pier column and the lower section 2 of the pier column. Mounting channels 13 are reserved at the corresponding positions of the upper section 1 of the pier column, the lower section 2 of the pier column and the rubber elastic layer 3 . The prestressed tendon 4 self-assembles through the rubber elastic layer 3 and connects the upper section 1 of the pier column with the lower section 2 of the pier column, thereby forming the main body of the pier. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com