Breathing type gravity prefabricated box ecological embankment structure and construction method thereof

A breathing and gravity-type technology, applied in botany equipment and methods, coastline protection, container cultivation, etc., can solve the problems of disappearing river water self-purification function, waste of building materials, poor economic benefits, etc., to achieve convenient construction and less waste of resources , the effect of tight deadlines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

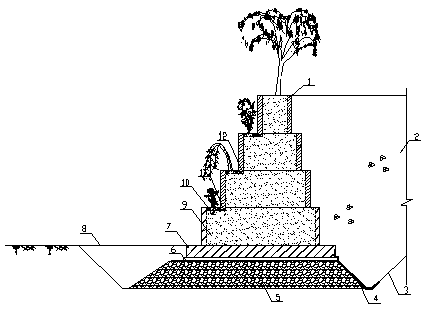

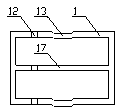

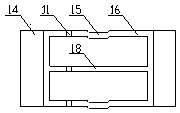

[0035] like figure 1 , figure 2 and image 3 As shown, a breathing type gravity-type prefabricated box ecological revetment structure includes a prefabricated box 1, a backfill 2, a gravel bed 5, a plain concrete cushion 6, a small prefabricated caisson 7, planting soil 9 and bottom protection Structure 10; the crushed stone foundation bed 5 is arranged on the river bank of the soft soil foundation, a plain concrete cushion 6 is arranged on the top of the crushed stone foundation bed 5, and a prefabricated small caisson 7 is arranged on the top of the plain concrete cushion 6. The small caisson 7 is provided with several prefabricated boxes 1, the front and rear of the several prefabricated boxes 1 are arranged in steps, and the interior of each prefabricated box 1 is provided with planting soil material 9; the front steps of the prefabricated box 1 The space distance for planting plants is reserved, and a bottom protection structure 10 is provided; the rear steps of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com