Intelligent underground layered well test injection allocator and flow automatic control and test system

An intelligent well and dispenser technology, applied in wellbore/well components, measurement, and production of fluids, etc., can solve the problem that the layered dynamic data cannot be monitored in real time, the complex artificial running and tripping work, waste of manpower, material resources and other problems. Time and other issues, to achieve the effect of saving manpower, smooth and scientific water injection, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

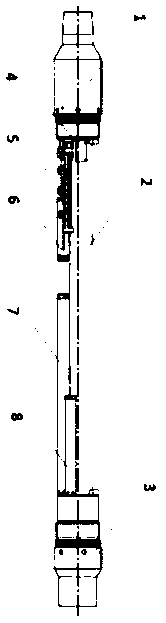

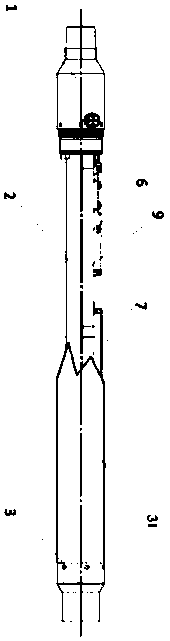

[0035] An intelligent downhole layered well test dispenser includes a work cylinder 31, an overflow pipe 2 sleeved in the work cylinder 31, and an upper joint 1 and a lower joint 3 respectively connected to the two ends of the work cylinder 31, The working barrel 31, the overflow pipe 2, the upper joint 1 and the lower joint 3 form an annular sealed cavity; the annular sealed cavity is provided with a flow meter 9, a self-control water nozzle 6, a well test test nipple 5, a control storage The module 8 and the battery unit 7, the water inlet 29 of the self-control water nozzle 6 is connected to the overflow pipe 2, and one end of the water outlet 30 of the self-control water nozzle 6 extends into the upper joint 1 and is connected externally with the upper joint 1 through the upper joint 1, and the water inlet 29 A flow meter 9 is set between the water outlet 30; the upper joint 1 is connected with a well test sub-joint 5; the lower joint 3 is connected with a battery unit 7 an...

Embodiment 2

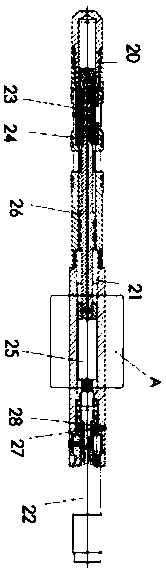

[0041] On the basis of Embodiment 1, the self-control water nozzle 6 also includes a flow control valve, a connecting rod 26, and a flow control cavity between the water inlet 29 and the water outlet 30. The flow control valve is composed of a valve sleeve 23 and a valve The valve sleeve 23 of the flow control valve in the flow control cavity is fixed on the inner wall of the flow control cavity, the valve core 24 of the flow control valve is connected to one end of the connecting rod 26, and the other end of the connecting rod 26 One end has a ball screw assembly 25 and a driving motor 22, and the connecting rod 26 is coaxially connected with the driving motor 22 through the ball screw assembly 25. When the driving motor 22 stretches out the connecting rod 26 through the ball screw assembly 25, the control The flow control valve in the flow chamber is opened, and the water inlet 29 and the water outlet 30 are connected; when the drive motor 22 retracts the connecting rod 26 th...

Embodiment 3

[0047] On the basis of Embodiment 2, the ball screw assembly 25 includes a ball screw pair and a rail groove 36 for radially fixing and axially sliding nuts of the ball screw pair, when the ball screw pair When the lead screw rotates, the nut of the ball screw pair slides axially along the guide rail groove 36; one end of the nut extends to form an inner cavity for the lead screw to fully penetrate into the nut, and the nut One end of the extension is connected with the connecting rod 26, and the other end of the nut is connected with the lead screw; the lead screw is connected with the drive motor 22 by coaxial transmission, and the guide rail groove 36 is parallel to the motor shaft of the drive motor 22, so The guide rail groove 36 and the drive motor 22 are relatively fixed.

[0048] In this example, if image 3 , Figure 4 As shown, the ball screw assembly 25 is a set that converts the rotational power of the motor into a fine linear motion that advances and retracts al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com