Low temperature resisting rubber pipe assembly

A technology of rubber hose assembly and low temperature resistance, which is applied in the field of low temperature resistant rubber hose assembly and low temperature resistant oil pipe connector, can solve the problems of high cost, unsuitable sealing of hose connecting structural parts, complicated preparation process, etc. The effect of good sealing and thermal insulation effect and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

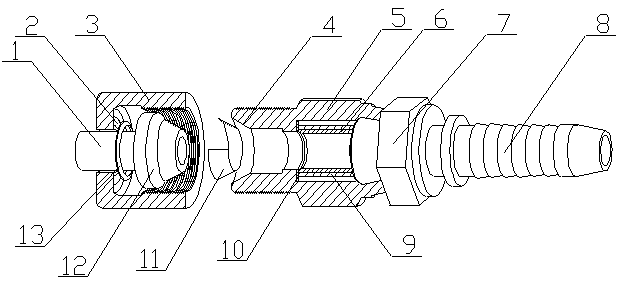

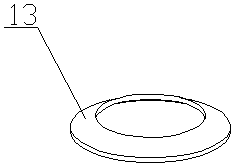

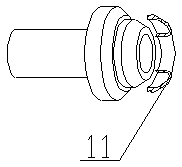

[0022] The low temperature resistant rubber hose assembly of the present invention is realized in this way, consisting of connecting pipe (1), annular groove (2), fastening screw sleeve (3), bowl-shaped groove (4), fixed pipe (5), inner liner pipe ( 6), hexagonal plate (7), pagoda connector (8), outer sealing sleeve (9), steel sheet (10), sealing packing ring (11), sealing head (12), sealing backing plate (13) and The support tube (14) is composed of one end of the support tube (14) connected to one end of the fixed tube (5) and communicated with each other. The outer wall of the support tube (14) is threaded, and the outer diameter of the support tube (14) is less than The outer diameter of the fixed tube (5), the inner diameter of the support tube (14) is smaller than the inner diameter of the fixed tube (5), the steel sheet (10) is placed on the end surface of the support tube (14), and is located in the fixed tube (5), the The steel sheet (10) is a multi-layer structure wi...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is: the sealing packing ring (11) is a single-layer conical ring, and there are multiple sealing rings on the outside, and there are multiple separation rings on the outside of the outer sealing sleeve (9). , and the outer side of the separation ring fits the inner wall of the fixed pipe (5); when in use, multiple sealing rings fit the wall of the bowl-shaped groove (4) respectively, and then perform multi-layer sealing, and the connecting pipe (1) and the support The sealing effect of the connection position of the pipe (14) is better, and the multiple partition rings on the outside of the outer sealing ring are respectively attached to the inner wall of the fixed pipe (5), and then multiple seals between the inner liner pipe (6) and the fixed pipe (5) are carried out. Layer sealing, better sealing effect;

[0026]The steel sheet (10) is a multi-layer structure with at least 3 layers, the thickness of the steel sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com