Stable pipeline heat dissipation module

A heat dissipation module and stable technology, applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., can solve the problem of low heat dissipation efficiency, achieve high heat dissipation efficiency, uniform distribution, and protect the effect of thermal interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

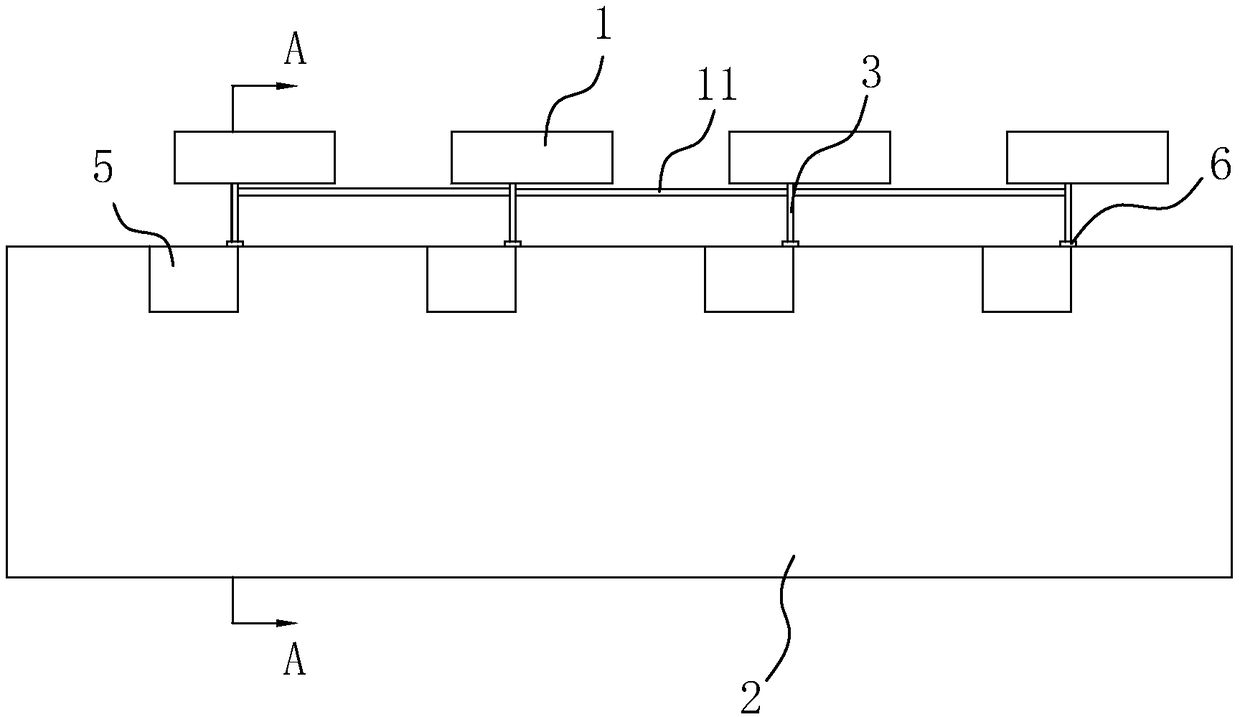

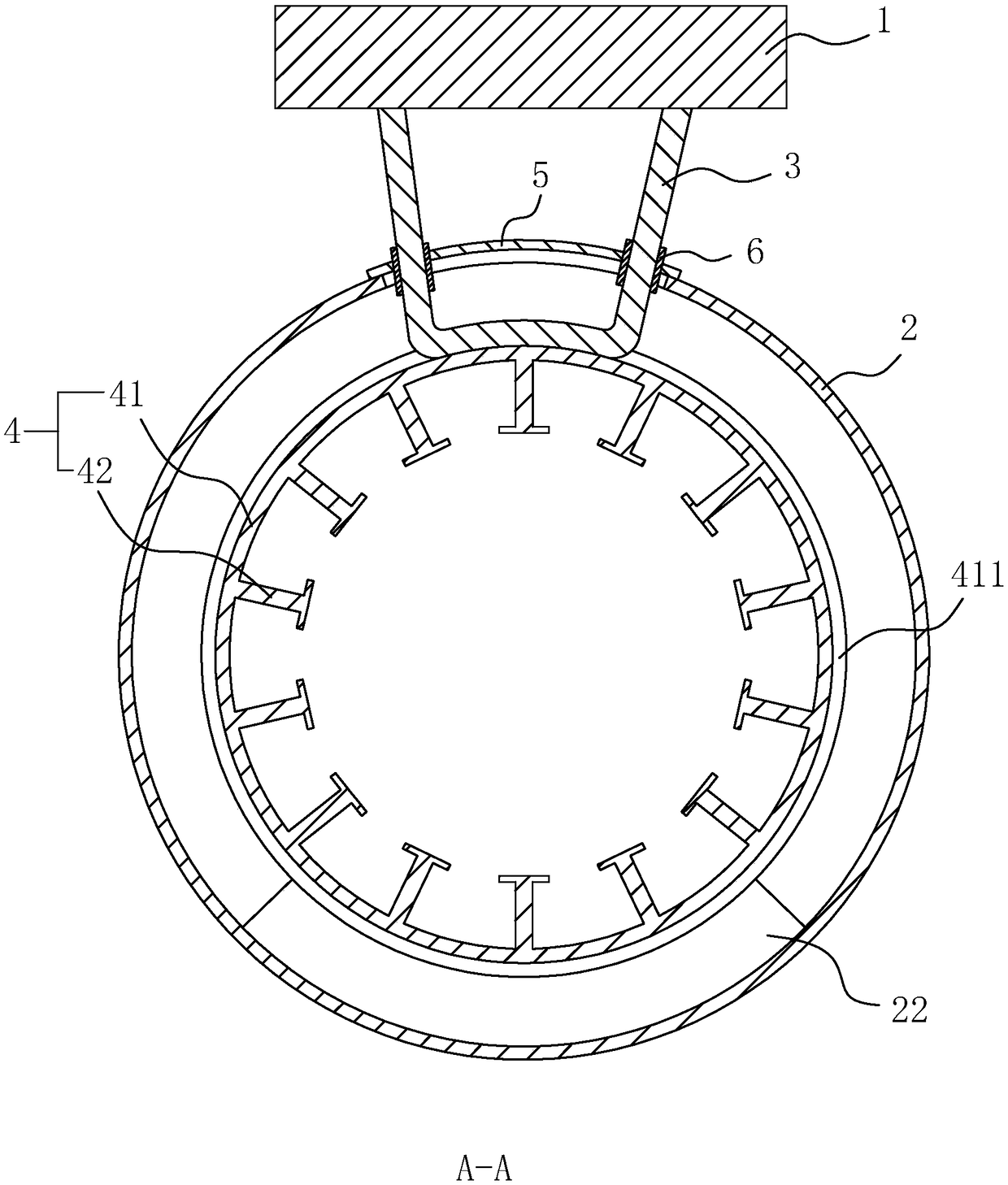

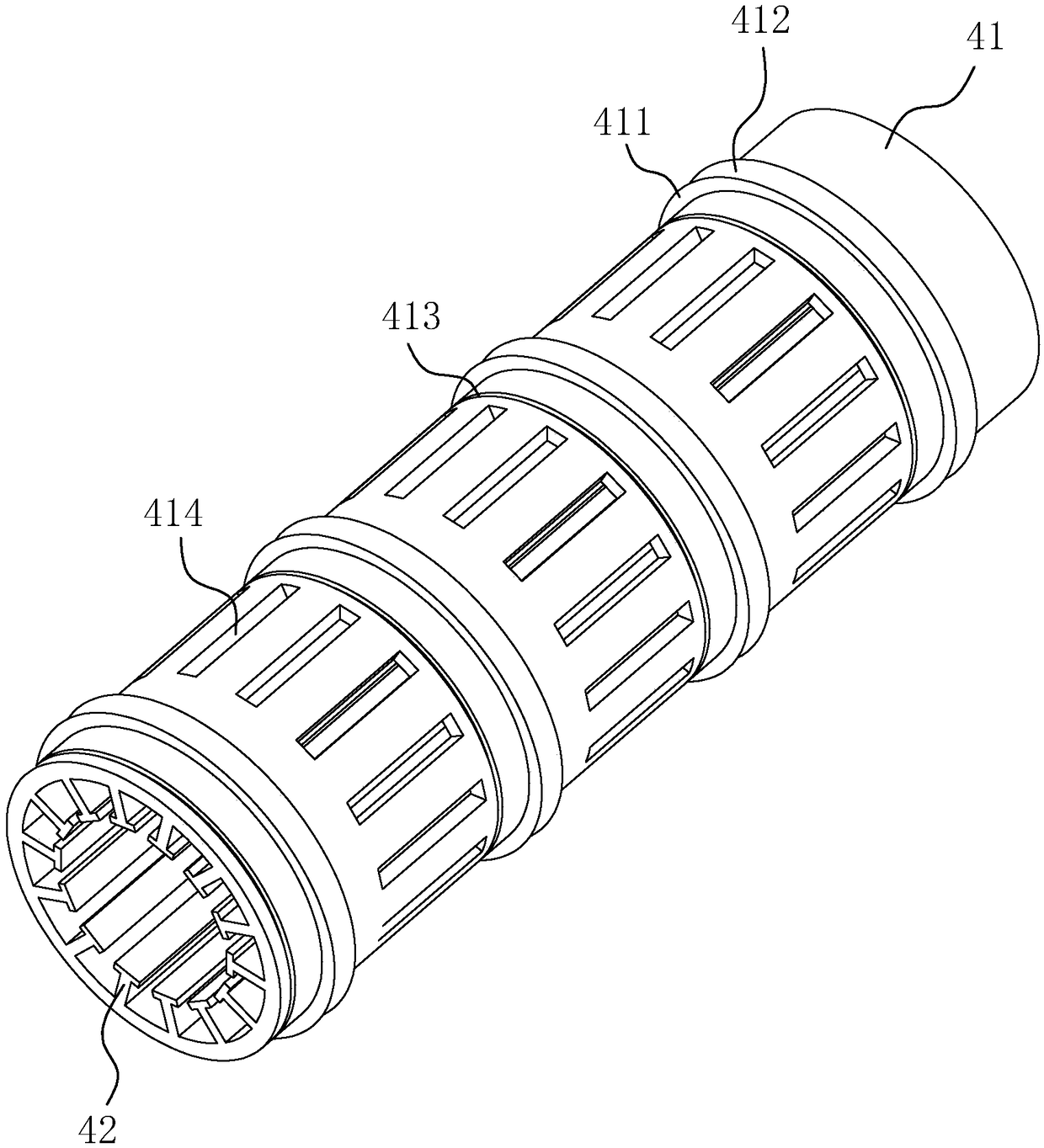

[0039] A stable pipe cooling module, such as figure 1 As shown, it includes: a number of heat absorbers 1 for assembling with the heating body, and a uniform heat pipe 11 is connected between adjacent heat absorbers 1; a diversion pipe 2, and a plurality of slots 21 are provided on the diversion pipe 2; The heat pipe 3 carried on the heat absorber 1; the heat dissipation structure 4 arranged in the flow guide pipe 2; and the sealing plate 5 carried on the flow guide pipe 2 for closing the slot 21, and the sealing plate 5 is provided with a heat conduction The socket 51 through which the tube 3 passes, and the sealing plate 5 is in sealing connection with the heat pipe 3 .

[0040] Specifically, the heat absorber 1 can be made of a material with good thermal conductivity such as copper alloy or aluminum alloy, which can be attached to the heating body so as to absorb and conduct the heat of the heating body. The uniform heat pipe 11 and the heat pipe 3 are evenly connected Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com