Rotation type air preheating system capable of achieving online cleaning and online cleaning method

A technology of air preheating and air preheater, which is applied in the direction of combustion methods, cleaning heat transfer devices, and removing solid residues. Effect with little temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further described below in conjunction with embodiment.

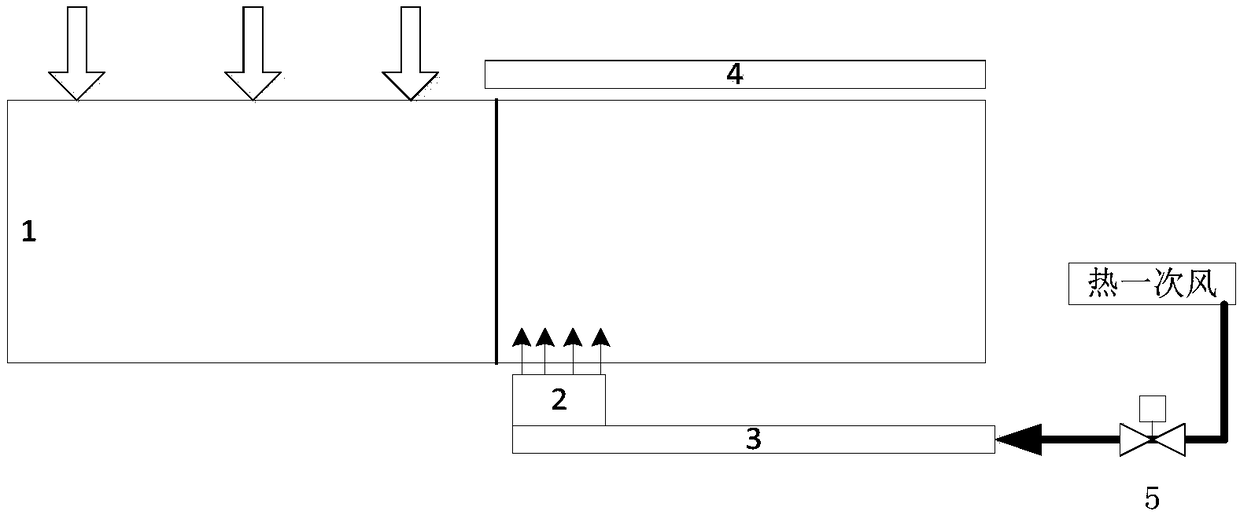

[0035] Such as figure 1 Shown is the rotary air preheating system that can be cleaned online in this embodiment, which includes a rotary air preheater 1, and the rotary air preheater 1 is provided with a flue gas channel, and the rotary air preheater system also includes The nozzle 2, the linear moving device 3 and the shielding plate 4, the linear moving device 3 is installed at the flue gas outlet end of the flue gas channel, the nozzle 2 is installed on the linear moving device, and the linear moving device 3 drives the nozzle 2 along the rotary air preheating The radial movement of the heater 1, the nozzle 2 faces the rotary air preheater, the nozzle 2 is connected to the hot primary air main pipe through the air pipe, and the hot primary air is led out from the hot primary air main pipe and sprayed to the rotary air preheater by the nozzle 2. The heat storage element at the cold end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com