Method of detecting periclase content in cement clinker

A technology of cement clinker and detection method, which is applied in the direction of chemical analysis by titration method, analysis by making materials undergo chemical reactions, material analysis by observing the influence of chemical indicators, etc., and can solve the problem of periclase content value Large size, long extraction time and other problems, to achieve the effect of improving dispersion, efficient separation, real and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for detecting periclase content in cement clinker, the steps are as follows:

[0023] S01, the cement clinker is broken and crushed and sieved (0.075mm square hole sieve, the same below), to obtain a clinker sample;

[0024] S02, according to the mass ratio of castor oil and absolute ethanol is 10:1, mix and prepare to obtain shielding agent, wherein the content of ricinoleic acid in castor oil is 85%;

[0025] S03. Weigh 0.2g of the clinker sample and place it in a 150mL ground-necked flask, add 16g of the prepared shielding agent, close the bottle mouth, place it in a 60°C water bath for heat preservation for 20min, and cool to room temperature;

[0026] S04. Add 10 g of ammonium nitrate and 40 g of absolute ethanol simultaneously to the ground-mouth flask, heat to reflux at 85° C. for 1 h, suction filter while hot, wash the precipitate with hot absolute ethanol and incorporate into the filtrate;

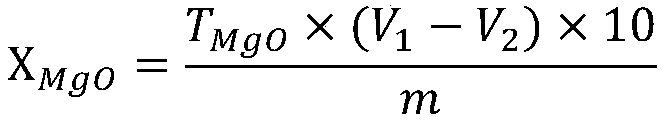

[0027] S05. After the filtrate obtained in step S04 was cool...

Embodiment 2

[0040] A method for detecting periclase content in cement clinker, the steps are as follows:

[0041] S01, the cement clinker is broken and crushed and sieved (0.075mm square hole sieve, the same below), to obtain a clinker sample;

[0042] S02, according to the mass ratio of castor oil and absolute ethanol is 12:1, mix and prepare to obtain shielding agent, wherein the content of ricinoleic acid in castor oil is 80%;

[0043] S03. Weigh 0.2g of the clinker sample and place it in a 150mL ground-necked flask, add 12g of the prepared shielding agent, close the bottle mouth, place it in a 50°C water bath for heat preservation for 15min, and cool to room temperature;

[0044] S04. Add 12 g of ammonium nitrate and 30 g of absolute ethanol simultaneously to the ground-mouth flask, heat to reflux at 85° C. for 4 h, suction filter while hot, wash the precipitate with hot absolute ethanol and incorporate into the filtrate;

[0045] S05. After the filtrate obtained in step S04 was cool...

Embodiment 3

[0047] A method for detecting periclase content in cement clinker, the steps are as follows:

[0048] S01, the cement clinker is broken and crushed and sieved (0.075mm square hole sieve, the same below), to obtain a clinker sample;

[0049] S02, according to the mass ratio of castor oil and absolute ethanol is 15:1, mix and prepare to obtain shielding agent, wherein the content of ricinoleic acid in castor oil is 80%;

[0050] S03. Weigh 0.2g of the clinker sample and place it in a 150mL ground-necked flask, add 12g of the prepared shielding agent, close the bottle mouth, place it in an ultrasonic water bath at 55°C for ultrasonic and heat preservation for 10min, and cool to room temperature;

[0051] S04. Add 10 g of ammonium nitrate and 36 g of absolute ethanol simultaneously to the ground-mouth flask, heat to reflux at 90° C. for 2 h, suction filter while hot, wash the precipitate with hot absolute ethanol and incorporate into the filtrate;

[0052] S05. After the filtrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com