Mud high-pressure filtering and compressed dewatering testing cavity and device

A technology for testing chambers and mud, applied in the field of mud high-pressure filtration compression dehydration test chambers and test devices, can solve the problems of narrow applicability of conclusions, single dehydration performance test indicators, poor reliability, etc. The effect of liquid separation equipment selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

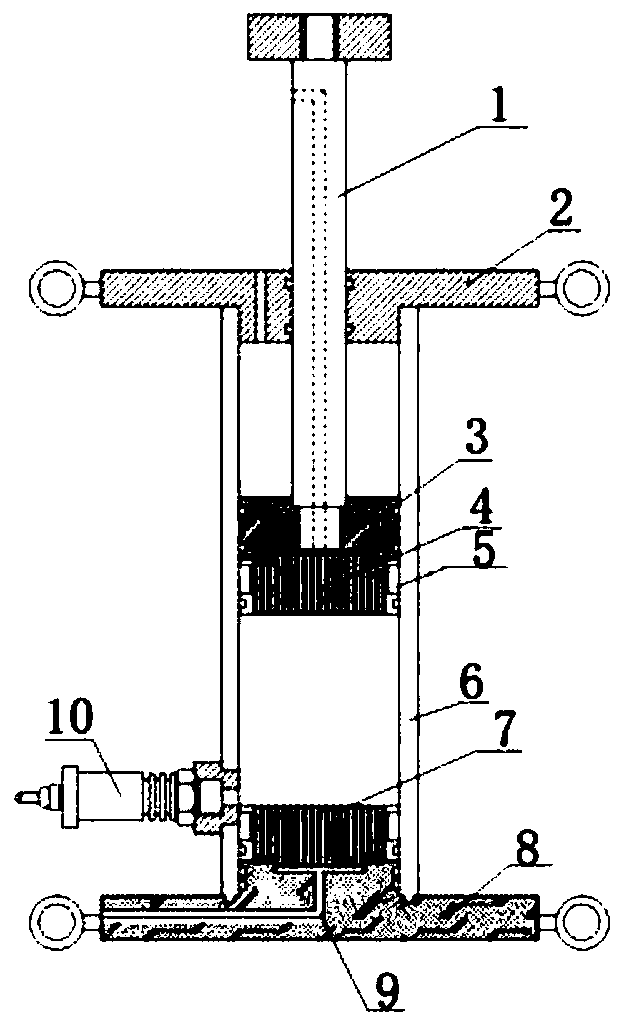

[0041] see figure 1 , a mud piston filtration compression dehydration test chamber, including: push rod 1, top cover 2, cylinder 6, piston 3, lower end permeable plate 7, base 9 and first water pressure transmitter 10.

[0042] The force applying push rod 1 is embedded in the through hole opened on the top cover 2, and can move axially, so that the dehydration pressure can be applied under the action of the externally connected power element; generally speaking, the power element can adopt hydraulic pressure. system so that changes in applied pressure can be acquired in real time.

[0043] The top cover 2 is detachably sealed on the top port of the cylinder 6 to form a cylindrical cavity with an openable upper end for pressing and dehydration operation.

[0044] The piston 3 abuts against the inner cavity wall of the cylinder 6 and is fixedly connected with the first end of the pushing rod 1, and can move along the cylinder under the driving of the pushing rod 1. The wall of...

Embodiment 2

[0052] see figure 1 , on the basis of Example 1, the structure of double-sided drainage is set to facilitate the research of this kind of solid-liquid separation process operation and equipment.

[0053] The cavity also includes: an upper permeable plate 4; the upper permeable plate 4 abuts against the lower end surface of the piston 3, thereby forming a solid-liquid separation structure similar to the lower permeable plate 7, and realizing the separation of the upper end and the lower end. Composite Structure.

[0054]Specifically, an upper liquid discharge channel is opened in the pushing rod 1 and communicates with the liquid outlet of the upper permeable plate 4 .

[0055] In order to facilitate the collection of liquid discharge, a first liquid collection tank is provided on the lower end surface of the piston 4, and the bottom of the first liquid collection tank communicates with the upper liquid discharge channel; above the first sump.

[0056] Further, the groove sh...

Embodiment 3

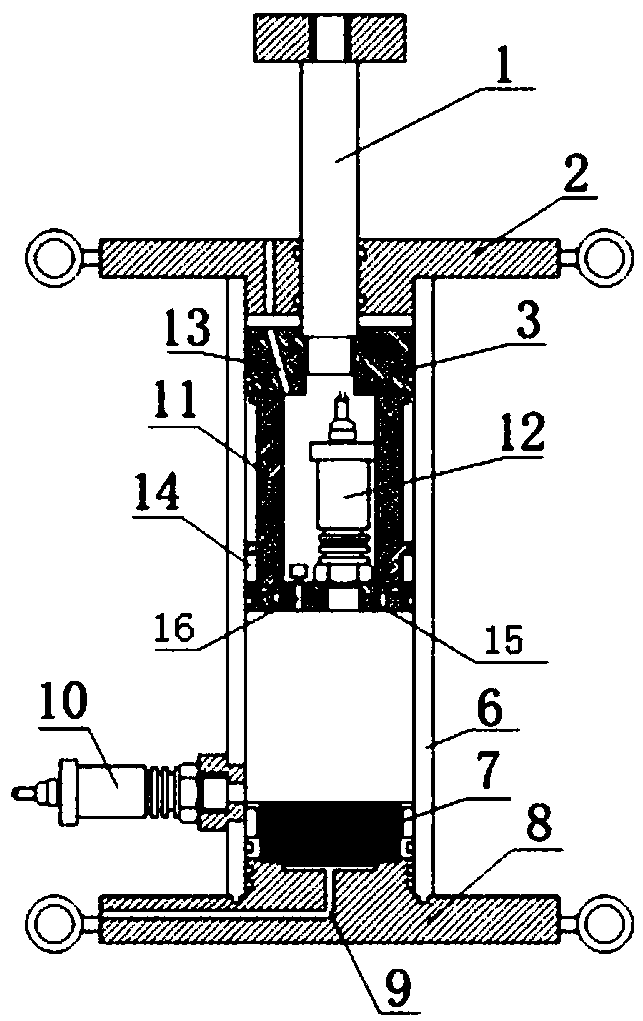

[0064] see figure 2 , On the basis of Embodiment 1, a single-ended drainage measurement structure is adopted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com