A self-supporting silicon carbon negative electrode material and preparation method thereof

A negative electrode material, self-supporting technology, applied in negative electrodes, nanotechnology for materials and surface science, battery electrodes, etc., can solve the problems of low Coulombic efficiency, poor cycle performance, poor electrochemical performance of batteries, etc. Cycle performance, low cost, and the effect of improving discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

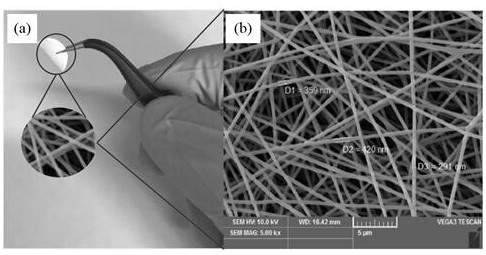

Embodiment 1

[0045] 1) Add 8.7 g DMF to the beaker, then add 1.3 g PAN for ultrasonic dispersion, then place the above mixture in a 60°C oil bath and stir for 6 h at a constant temperature. After the PAN is completely dissolved, the spinning solution is obtained;

[0046] 2) Use a 20 ml syringe to absorb the spinning solution obtained in step 1) and place it in the container loading device of the electrospinning machine, fix it on the injection flow rate controller, turn on the electrospinning equipment, and set the electrospinning process parameters: spinning Temperature 45 ℃, humidity 36%, 22 G needle, voltage 23 Kv, speed 200r / min, flow rate 2 ul / min, the distance between the needle and the receiving plate was 21 cm, and then electrospinning was carried out to obtain composite nanofibers.

[0047] 3) Place the composite nanofibrous membrane obtained in step 2) in a 60 °C forced air drying oven for 6 h to remove the solvent, then cut it into a square piece of 5×9 cm, and then use it on a ...

Embodiment 2

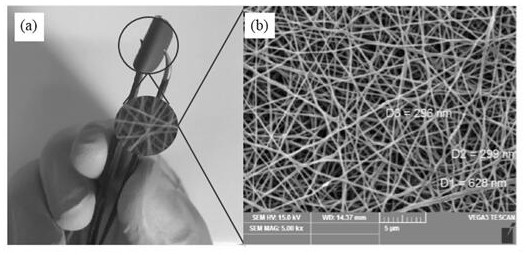

[0049] 1) Accurately weigh 0.025 g of nano-silicon powder into a 50 ml small beaker, add an appropriate amount of KH580 dropwise to soak the nano-silicon powder, then add 8.7 g of DMF and ultrasonically disperse for 20 min, add 1.3 g of PAN, and place at 60 °C Stir in the oil bath at constant temperature for 6 h, and after the PAN is completely dissolved, a brown emulsion is obtained, which is the spinning solution;

[0050] 2) Use a 20 ml syringe to absorb the spinning solution obtained in step 1) and place it in the container loading device of the electrospinning machine, fix it on the injection flow rate controller, turn on the electrospinning equipment, and set the electrospinning process parameters: spinning Temperature 45 ℃, humidity 36%, 22 G needle, voltage 23 Kv, rotation speed 200r / min, flow rate 2 ul / min, the distance between the needle and the receiving plate was 21 cm, and then electrospinning was carried out to obtain Si 0.025 / PAN composite nanofibers.

[0051]...

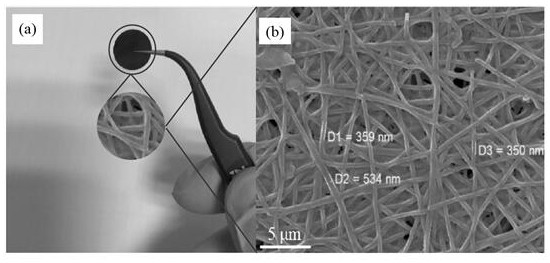

Embodiment 3

[0053] 1) Accurately weigh 0.05 g of nano-silicon powder into a 50 ml small beaker, add an appropriate amount of KH580 dropwise to soak the nano-silicon powder, then add 8.7 g of DMF and ultrasonically disperse for 20 min, add 1.3 g of PAN, and place at 60 °C Stir in the oil bath at constant temperature for 6 h, and after the PAN is completely dissolved, a brown emulsion is obtained, which is the spinning solution;

[0054] 2) Use a 20 ml syringe to absorb the spinning solution obtained in step 1) and place it in the container loading device of the electrospinning machine, fix it on the injection flow rate controller, turn on the electrospinning equipment, and set the electrospinning process parameters: spinning Temperature 45 ℃, humidity 36%, 22 G needle, voltage 23 Kv, rotation speed 200r / min, flow rate 2 ul / min, the distance between the needle and the receiving plate was 21 cm, and then electrospinning was carried out to obtain Si 0.05 / PAN composite nanofibers.

[0055] 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com