A kind of graphene coated silicon composite material and its preparation method and application

A silicon composite material, graphene coating technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of complex preparation process and high cost, and achieve the effects of wide source, simple method and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

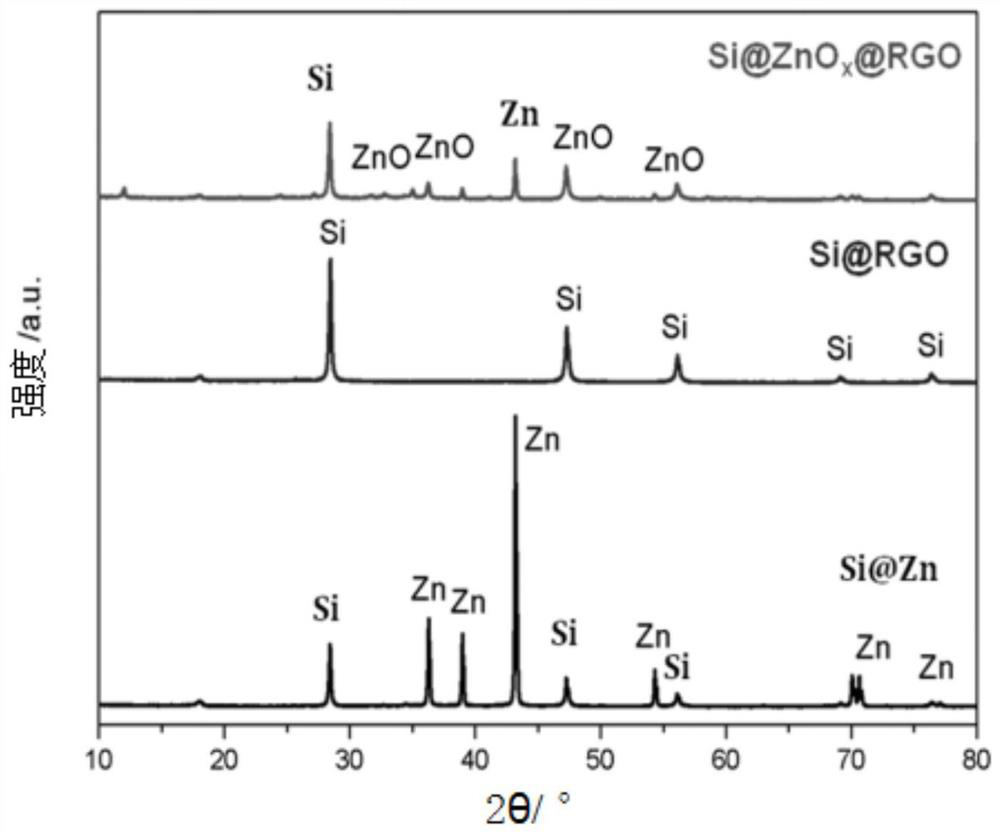

Embodiment 1

[0038] A preparation method of Si@RGO in this embodiment, the specific preparation steps are as follows:

[0039] (1) Add 3.0 g of graphite to a mixture of 360 mL of sulfuric acid and 40 mL of concentrated phosphoric acid, and cool in an ice-water bath. Very slowly 6.0 grams of potassium permanganate was added to the mixture. All operations are performed very slowly. The reaction was then heated to 50°C and mechanically stirred for 24 hours. The reaction was cooled to room temperature and poured slowly into a mixture of ice (400 mL) and 30 mL of 30% hydrogen peroxide. The solution was centrifuged, washed with 500 mL of 5% HCl, and then deionized water until the pH value was around 7, and the obtained product was vacuum-dried at 50° C. to remove water to obtain graphite oxide. Weigh an appropriate amount of graphite oxide and disperse it in deionized water, and ultrasonicate for 30 minutes to prepare a 1.0 mg / mL graphene oxide suspension.

[0040] (2) 0.7 g of silicon powde...

Embodiment 2

[0048] A preparation method of Si@RGO in this embodiment, the specific preparation steps are as follows:

[0049] (1) The preparation method of the graphene oxide suspension of 1.0 mg / mL is the same as that of Example 1.

[0050] (2) 0.5 g of silicon powder and 0.5 g of zinc powder are mixed and put into a ball mill jar, and ball milled at 300 rpm for 24 hours to obtain zinc-coated silicon (Si@Zn) particles, which are then ultrasonically dispersed in deionized water to obtain Si@ Zn mixture.

[0051] (3) Mix 700 mL of 1.0 mg / mL graphene oxide suspension with the Si@Zn mixture obtained in step (2), stir and react for 12 hours, and filter to obtain Si@ZnO x The @RGO composite material was soaked in excess 0.1M hydrochloric acid for 12 hours, filtered again, and dried to obtain the Si@RGO composite material.

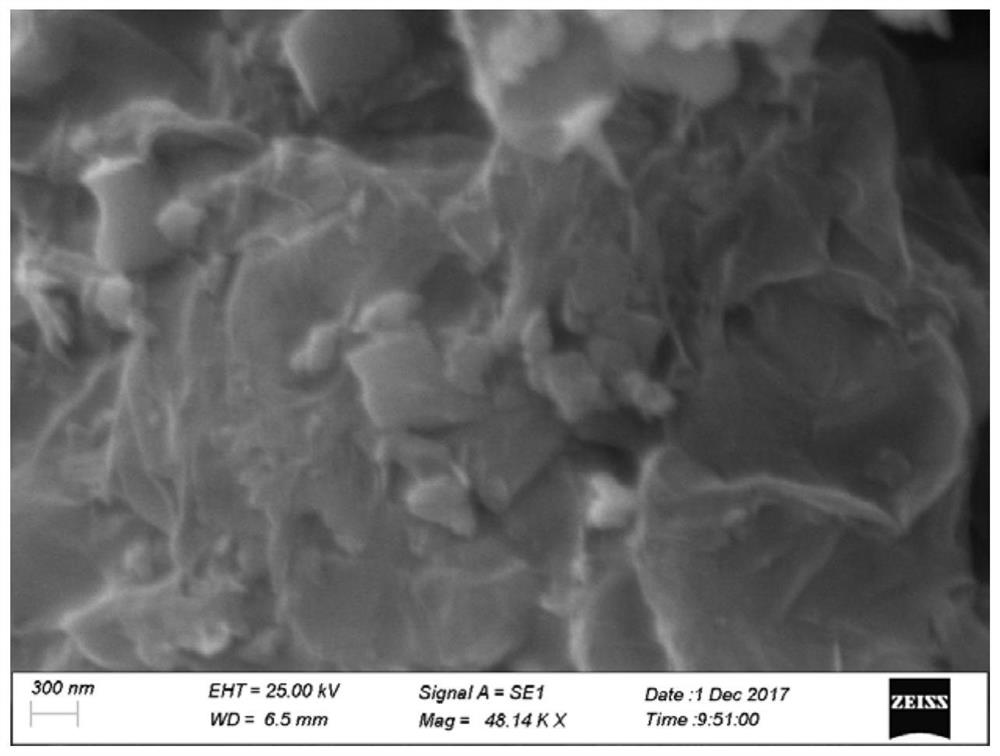

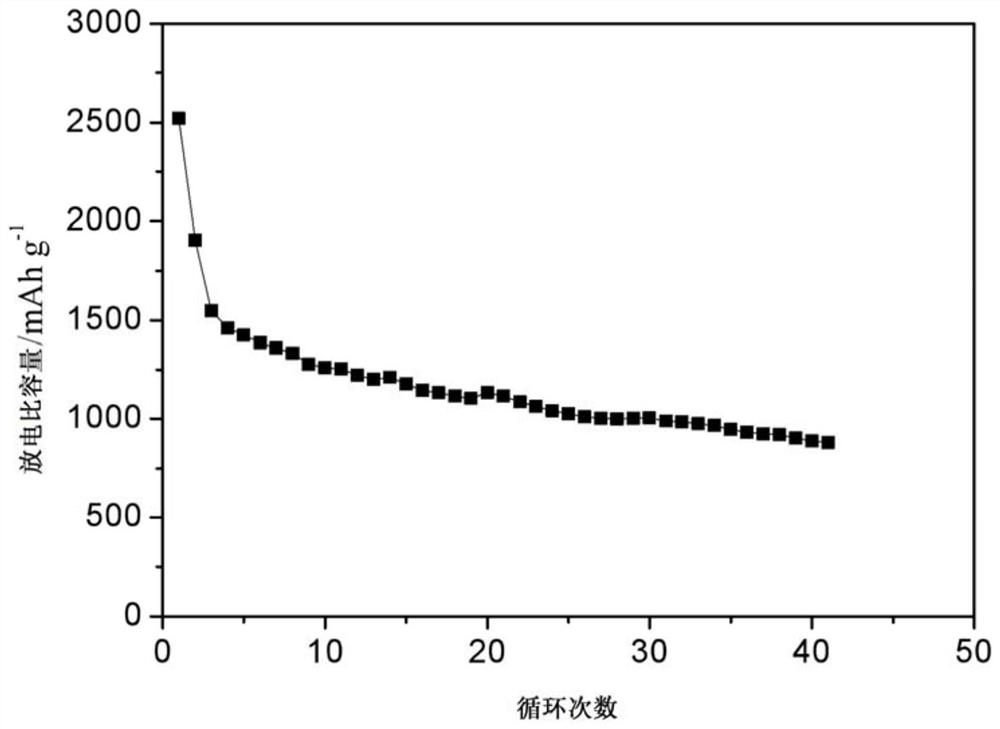

[0052] The electrochemical performance test method of Si@RGO prepared in this example is the same as that in Example 1. The cycle performance curve of Si@RGO obtained at ...

Embodiment 3

[0055] A preparation method of Si@RGO in this embodiment, the specific preparation steps are as follows:

[0056] (1) The preparation method of the graphene oxide suspension of 1.0 mg / mL is the same as that of Example 1.

[0057] (2) 0.3 g of silicon powder and 0.7 g of zinc powder were mixed and put into a ball mill jar, and ball milled at 300 rpm for 18 hours to obtain zinc-coated silicon (Si@Zn) particles, which were then ultrasonically dispersed in deionized water to obtain Si@ Zn mixture.

[0058] (3) Mix 300 mL of 1.0 mg / mL graphene oxide suspension with the Si@Zn mixture obtained in step (2), stir and react for 12 hours, and filter to obtain Si@ZnO x The @RGO composite material was soaked in excess 0.1M hydrochloric acid for 12 hours, filtered again, and dried to obtain the Si@RGO composite material.

[0059] The electrochemical performance test method of Si@RGO prepared in this example is the same as that in Example 1, and the cycle performance curves of Si@RGO obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com