Concrete crack repair material and its preparation method and use method

A technology for repairing cracks and concrete, which is applied in the field of building materials. It can solve the problems of inconsistent temperature deformation between repairing materials and concrete, inapplicability of small cracks, and no crack repairing materials, etc., to achieve excellent water retention performance, increase strength, and reduce water-cement ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

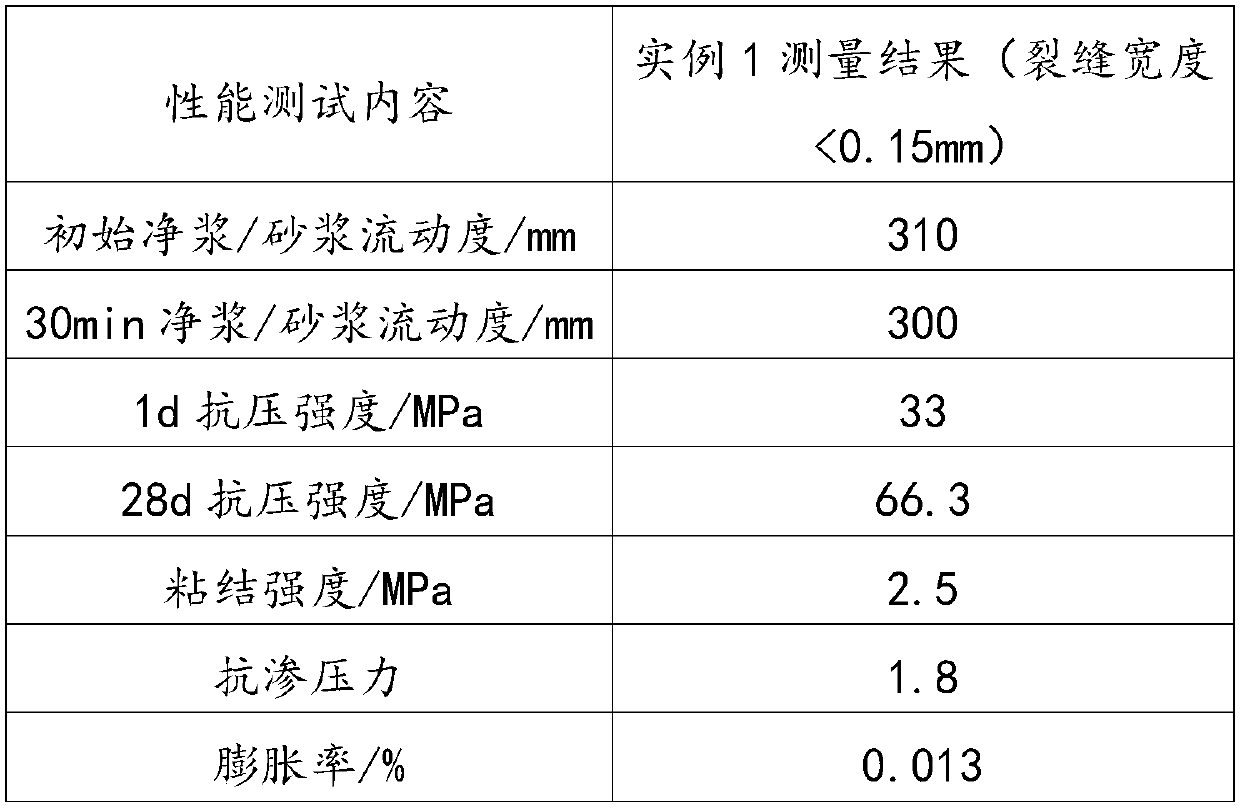

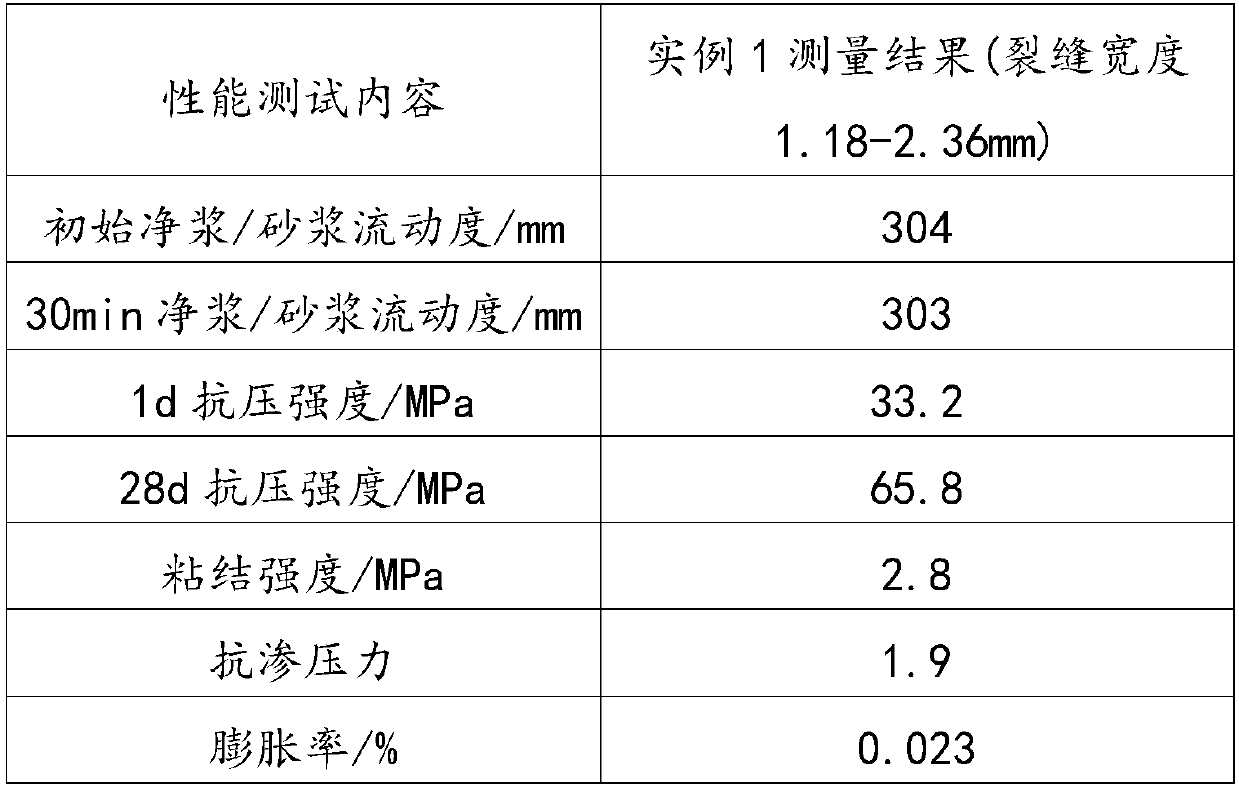

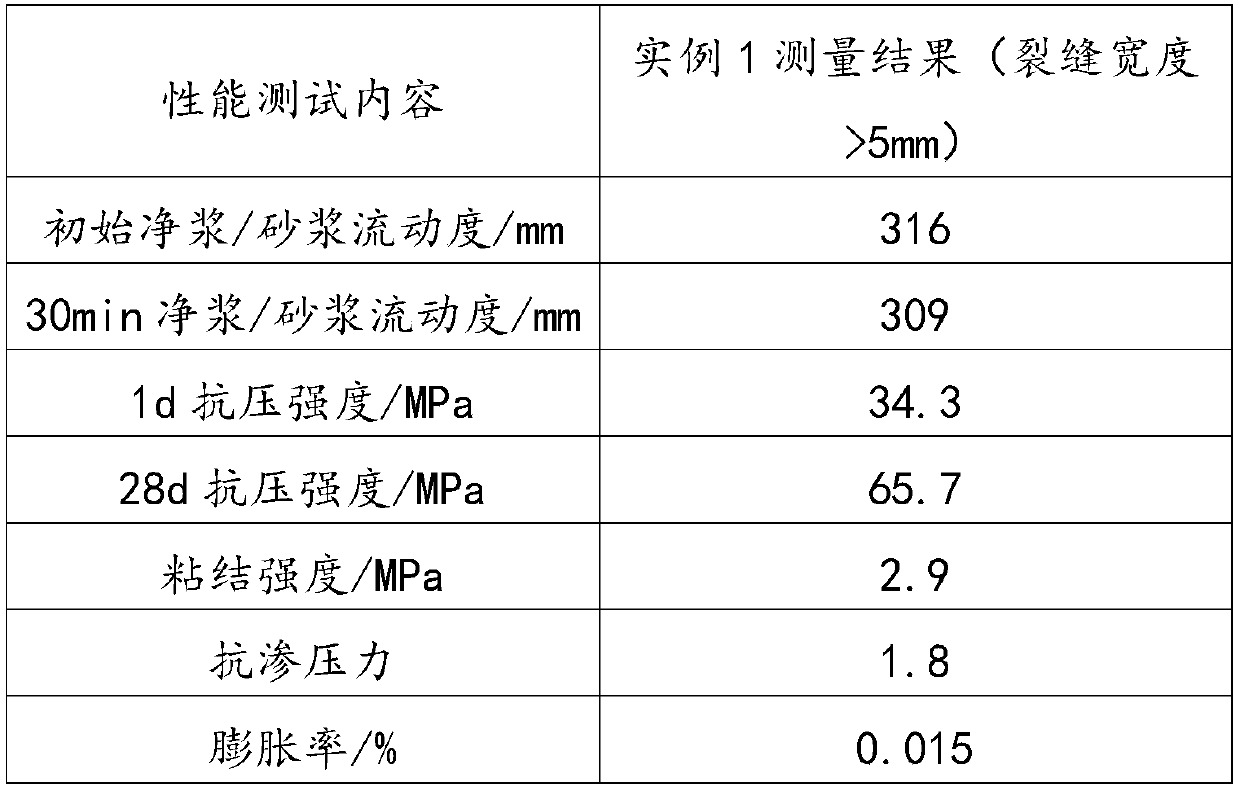

Embodiment 1

[0035]According to the technical scheme of the present invention, a kind of adjustable concrete crack repair material prepared by wet grinding process is prepared, and its components are 20 parts of waste glass, 30 parts of mineral powder, 40 parts of Portland cement, 0.2 parts of water reducer, 0.1 parts of molasses, 0.05 parts of triethanolamine, 0.02 parts of Wenlun glue, 0.1 parts of azodicarbonamide, 0.03 parts of defoamer, 8.5 parts of polyacrylate emulsion, 1 part of dispersible latex powder, fine Sand 0 parts.

[0036] The present invention also provides a preparation method of an adjustable concrete crack repair material prepared by a wet grinding process, comprising the following steps:

[0037] (1) Mix waste glass, mineral powder, portland cement, water reducing agent and molasses in proportion, then place them in a wet mill and add 25 parts of water to grind for 15 minutes.

[0038] (2) Mix the slurry in step 1 with azodicarbonamide, Wenlun rubber, defoamer, polya...

Embodiment 2

[0043] According to the technical scheme of the present invention, a kind of adjustable concrete crack repair material prepared by wet grinding process is prepared, and its components are 20 parts of waste glass, 30 parts of mineral powder, 40 parts of Portland cement, 0.25 parts of water reducer, 0.2 parts of molasses, 0.05 parts of triethanolamine, 0.02 parts of Wenlun glue, 0.1 parts of azodicarbonamide, 0.25 parts of defoamer, 8.4 parts of polyacrylate emulsion, 1 part of dispersible latex powder, fine Sand 22 parts.

[0044] The present invention also provides a preparation method of an adjustable concrete crack repair material prepared by a wet grinding process, comprising the following steps:

[0045] (1) Mix waste glass, mineral powder, portland cement, water reducer and molasses in proportion, then place them in a wet mill and add 32 parts of water to grind for 15 minutes.

[0046] (2) Mix the slurry in step 1 with azodicarbonamide, Wenlun rubber, defoamer, polyacryl...

Embodiment 3

[0051] According to the technical scheme of the present invention, a kind of adjustable concrete crack repairing material prepared by wet grinding process is prepared. In parts by weight, its components are 30 parts of waste glass, 20 parts of mineral powder, 35 parts of Portland cement, 0.2 parts of water reducer, 0.3 parts of molasses, 0.1 parts of triethanolamine, 0.2 parts of Wenlun glue, 0.4 parts of azodicarbonamide, 0.05 parts of defoamer, 10 parts of polyacrylate emulsion, 5 parts of dispersible latex powder, fine Sand 40 parts.

[0052] The present invention also provides a preparation method of an adjustable concrete crack repair material prepared by a wet grinding process, comprising the following steps:

[0053] (1) Mix waste glass, mineral powder, portland cement, water reducing agent and molasses in proportion, then place them in a wet mill and add 30 parts of water to grind for 15 minutes.

[0054] (2) Mix the slurry in step 1 with azodicarbonamide, Wenlun rubb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com