Processing method of elephant grass silage

A processing method and feed technology, which is applied in the processing field of elephant grass silage, can solve the problems of moldy, mildew, and rot of silage, and achieve the effect of improving silage quality, improving quality, and avoiding mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

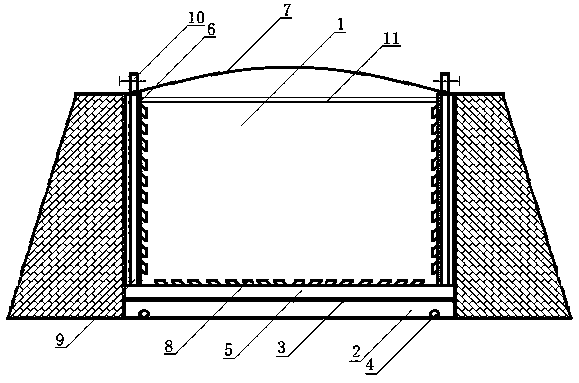

Image

Examples

Embodiment 1

[0028] A processing method for elephant grass silage, the processing method comprising the steps of:

[0029] (1) Air-dry the fresh elephant grass until the moisture content is 55%, and then cut the elephant grass into 3 cm long pieces to obtain the elephant grass raw material;

[0030] (2) air-drying fresh sugarcane leaves until the water content is 40%, and then cutting the sugarcane leaves into 3 cm long sections to obtain sugarcane leaf raw materials;

[0031] (3) Mix the elephant grass silage raw materials evenly to obtain a mixture, which is composed of 600 parts by weight of elephant grass raw materials, 100 parts by weight of sugarcane leaf raw materials, 200 parts by weight of soybean meal, and 60 parts by weight of corn flour ;

[0032] (4) Spraying a fermented liquid on the bottom and side walls of the silo, the fermented liquid is composed of 100 parts by weight of water, 3 parts by weight of starch, 1 part by weight of erythritol, and 2 parts by weight of amino a...

Embodiment 2

[0035] A processing method for elephant grass silage, the processing method comprising the steps of:

[0036] (1) Air-dry the fresh elephant grass until the moisture content is 65%, and then cut the elephant grass into 5 cm long pieces to obtain the elephant grass raw material;

[0037] (2) air-drying fresh sugarcane leaves until the water content is 60%, and then cutting the sugarcane leaves into 5cm-long sections to obtain sugarcane leaf raw materials;

[0038] (3) Mix the elephant grass silage raw materials evenly to obtain a mixture, which is composed of 800 parts by weight of elephant grass raw materials, 150 parts by weight of sugarcane leaf raw materials, 300 parts by weight of soybean meal, and 80 parts by weight of corn flour ;

[0039] (4) Spraying a fermented liquid on the bottom and side walls of the silo, the fermented liquid is composed of 120 parts by weight of water, 5 parts by weight of starch, 2 parts by weight of erythritol, and 4 parts by weight of amino a...

Embodiment 3

[0042] A processing method for elephant grass silage, the processing method comprising the steps of:

[0043] (1) Air-dry the fresh elephant grass until the moisture content is 60%, and then cut the elephant grass into 4 cm long pieces to obtain the elephant grass raw material;

[0044] (2) Air-drying the fresh sugarcane leaves until the water content is 50%, and then cutting the sugarcane leaves into 4 small sections to obtain the sugarcane leaf raw materials;

[0045] (3) Mix the elephant grass silage raw materials evenly to obtain a mixture, which is composed of 700 parts by weight of elephant grass raw materials, 120 parts by weight of sugarcane leaf raw materials, 250 parts by weight of soybean meal, and 70 parts by weight of corn flour ;

[0046] (4) Spraying a fermented liquid on the bottom and side walls of the silo, the fermented liquid is composed of 110 parts by weight of water, 4 parts by weight of starch, 1.5 parts by weight of erythritol, and 3 parts by weight o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com