Oil-in-water emulsion electric field demulsification apparatus

A technology of oil-in-water emulsion and demulsification device, which is applied in the directions of grease/oily substance/float removal device, magnetic field/electric field water/sewage treatment, liquid separation, etc. Complex and other problems, to achieve the effect of simple main structure and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

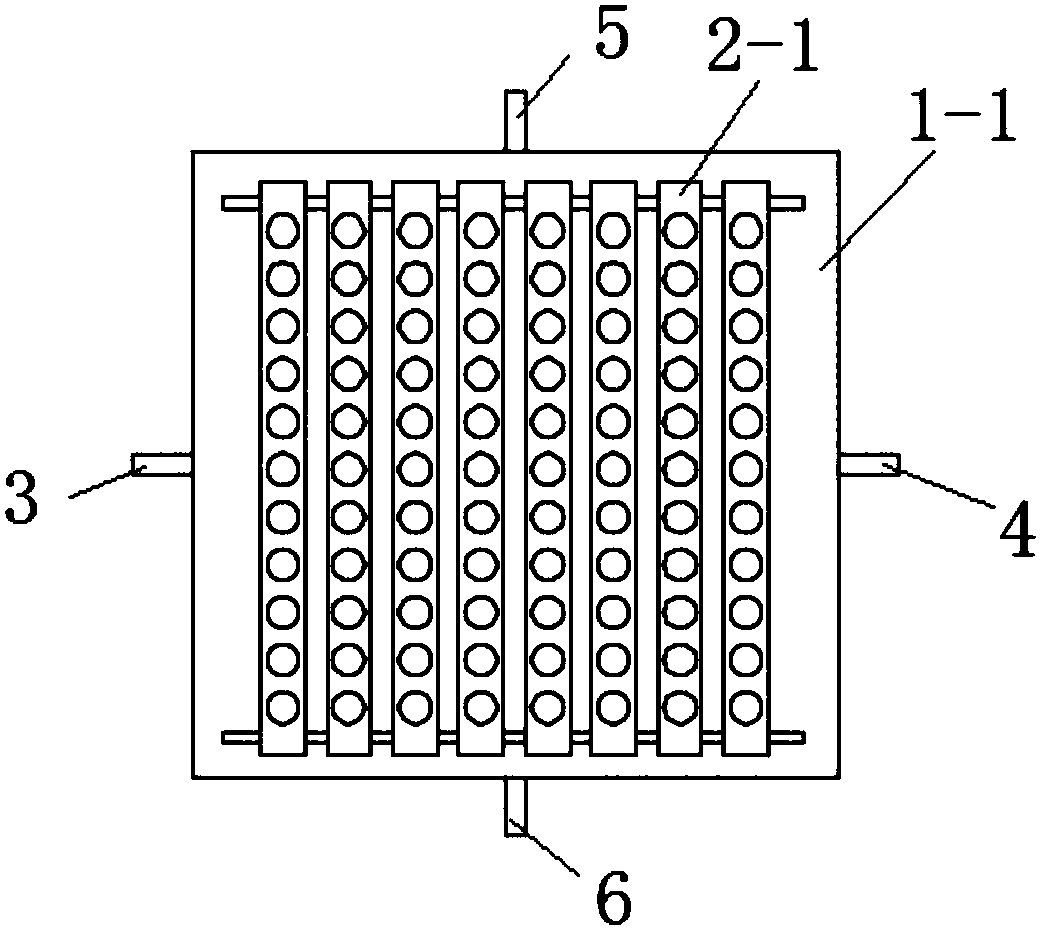

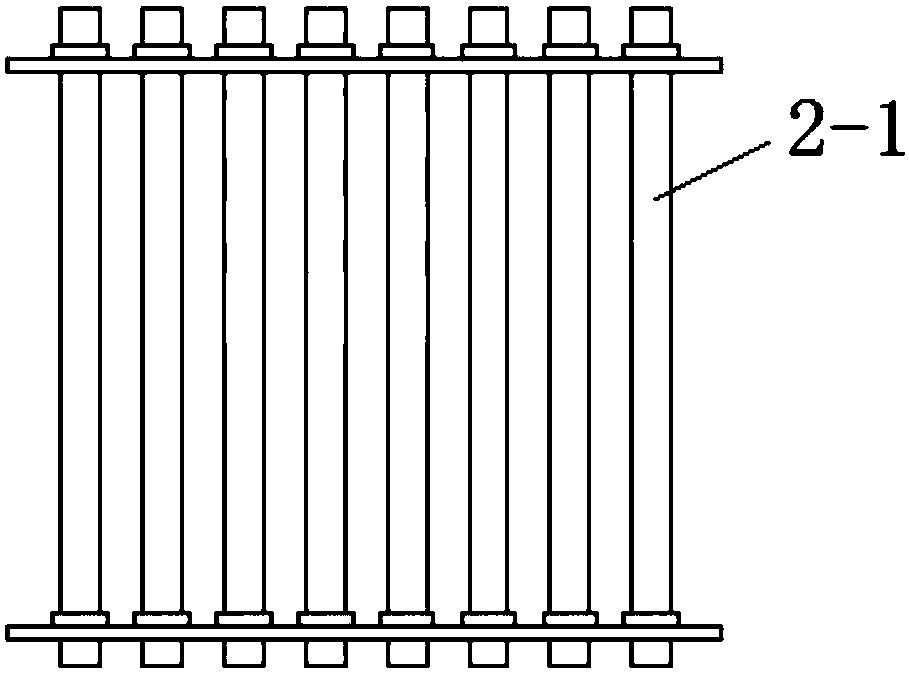

Embodiment 1

[0044] Static experiment: take 1000mL oil-in-water emulsion, the oil content is 0.5%. Under the conditions of voltage 800v, frequency 50Hz, and duty cycle 50%, it acts for a total of two hours. The main body of the oil-water separator is a square cylinder, and the electrode assembly is an integrated rectangular electrode assembly. The number of single electrodes installed is 50, the distance between adjacent electrodes is 10mm, and the diameter of a single electrode is 5mm. The distance between the electrode assembly and the inner wall of the oil-water separator is kept at 15 mm, and the four rod-shaped metal electrodes located in the center of the orifice plate are used as positive electrodes, and the rest are used as negative electrodes. After the electric field is applied, the demulsification rate reaches 94.53%.

Embodiment 2

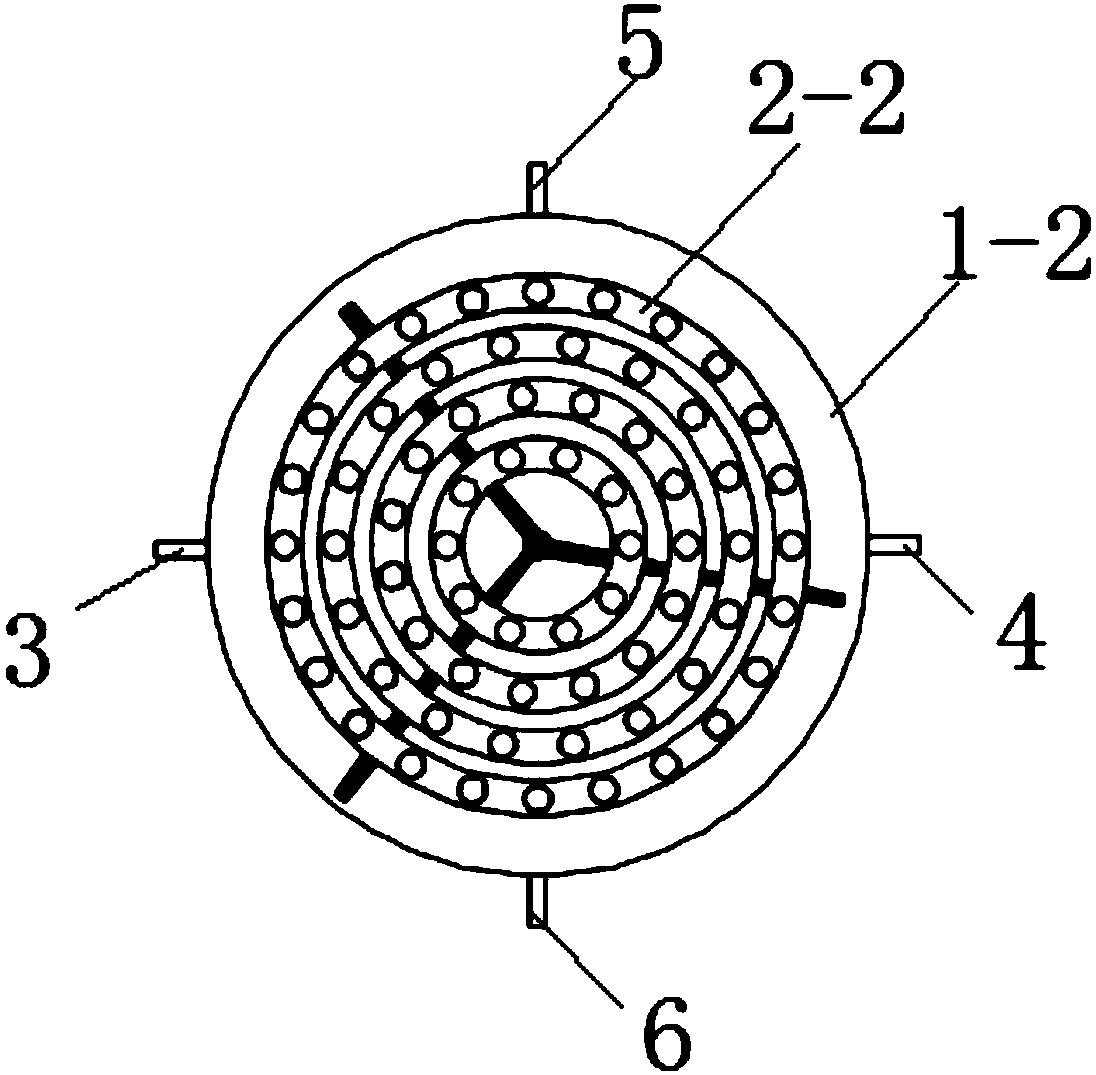

[0046] Static experiment: take 1000mL oil-in-water emulsion, the oil content is 0.5%. Under the conditions of voltage 900v, frequency 75Hz, and duty cycle 50%, it works for a total of two hours. The main body of the oil-water separator is a circular cylinder, and the electrode assembly is an integrated ring-shaped arrangement of electrode assemblies. The number of single electrodes installed is 47, the angle difference between adjacent electrodes is 30°, and the diameter of a single electrode is 5mm. The electrode assembly The distance from the inner wall of the oil-water separator is kept at 12mm, and one metal electrode located in the center of the orifice plate is used as the positive electrode, and the rest are used as the negative electrode. After the electric field acts, its demulsification rate reaches 95.97%.

Embodiment 3

[0048] Static experiment: take 1000mL oil-in-water emulsion, the oil content is 1%. Under the conditions of voltage 1000v, frequency 50Hz, and duty cycle 30%, it works for a total of two hours. The main body of the oil-water separator is a square cylinder, and the electrode assembly is a split rectangular electrode assembly. The number of small units installed is 8, and the number of single electrodes installed is 64. The distance between adjacent electrodes is 5mm. The diameter is 5mm. The distance between the electrode assembly and the inner wall of the oil-water separator is kept at 10mm. The metal electrodes of 1-10 small units located on the left side of the electrode assembly are used as positive electrodes, and the rest are used as negative electrodes. After the electric field is applied, the demulsification rate reaches 98.61%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com