Lead-free piezoelectric texture composite material applied in high-power-density energy collection device and preparation method and application thereof

A technology with high power density and energy harvesting, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc. Solve the problems of low energy density of electric ceramics, and achieve the effect of significant electromechanical conversion anisotropy and dielectric constant suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

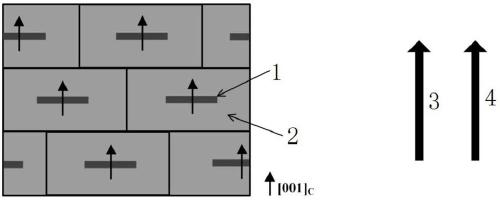

[0040] Specific implementation mode one: combine figure 1 This embodiment is specifically described. The general chemical formula of the lead-free piezoelectric texture composite material applied to high power density energy harvesting devices in this embodiment is (1-x)(Ba 1-y Ca y )(Ti 1-z m z )O 3 / xBaTiO 3 , where M is Sn or Hf, 0.01≤x≤0.20, 0.01≤y≤0.12, 0.01≤z≤0.15;

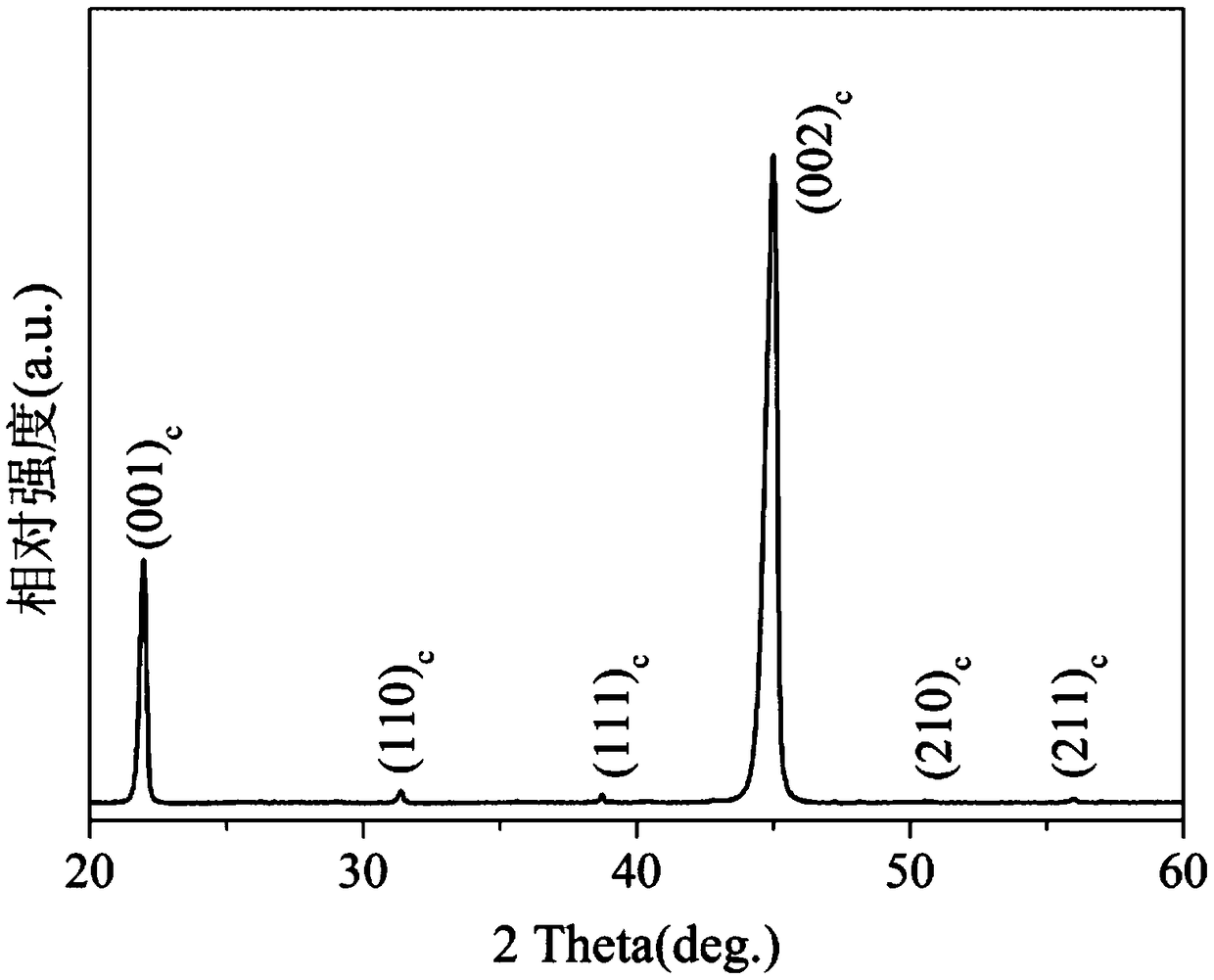

[0041] The lead-free piezoelectric texture composite material applied to high power density energy harvesting devices is developed along [001] c Composition of oriented grains with preferred orientation; the grain size of the oriented grains is 5 μm to 50 μm; the oriented grains have a core-shell structure, and the core is BaTiO with a tetragonal phase (T) structure and a sheet-like morphology 3 , the shell is a (Ba 1-y Ca y )(Ti 1-z m z )O 3 , where M is Sn or Hf, 0.01≤y≤0.12, 0.01≤z≤0.15;

[0042] The lead-free piezoelectric texture composite material applied to high power density energy harves...

specific Embodiment approach 2

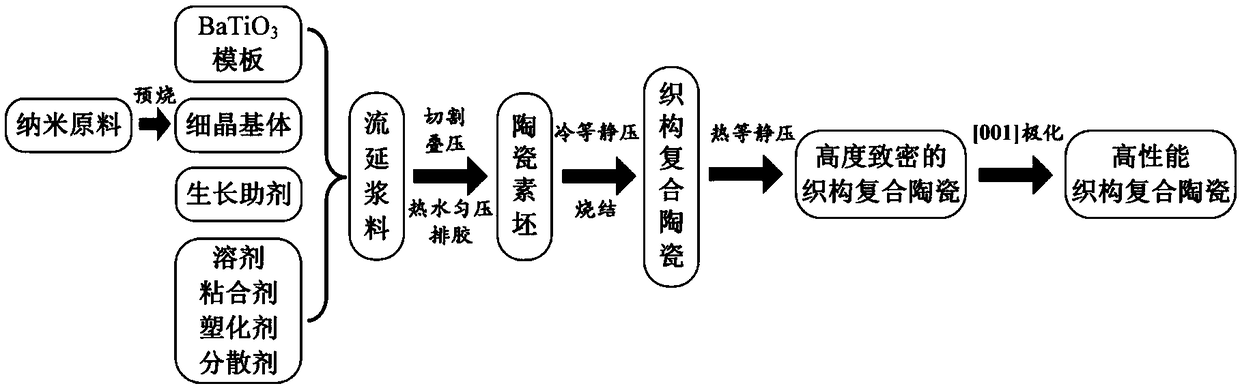

[0043] Specific implementation mode two: combination figure 2 Describe this embodiment in detail. In this embodiment, a method for preparing a lead-free piezoelectric textured composite material applied to high power density energy harvesting devices is completed according to the following steps:

[0044] 1. Preparation of fine crystal shell matrix powder:

[0045] According to the general chemical formula (Ba 1-y Ca y )(Ti 1-z m z )O 3 The stoichiometric ratio weighs the powder, when M is Sn, weighs BaCO 3 Powder, CaCO 3 Powder, TiO 2 Powder and SnO 2 Powder, when M is Hf, weigh BaCO 3 Powder, CaCO 3 Powder, TiO 2 Powder and HfO 2 powder, and then put the weighed powder in a ball milling tank, add absolute ethanol as a ball milling medium, use a planetary ball mill to mill for 12h to 120h, dry after ball milling, and grind evenly to obtain fine-grained raw materials, fine-grained raw materials Put it in a corundum crucible, under the condition of temperature of ...

specific Embodiment approach 3

[0061] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the TiO described in step one 2 The particle size of the powder is ≤100nm; the SnO described in step 1 2 The particle size of the powder is ≤100nm; the HfO described in step 1 2 The particle size of the powder is ≤100nm. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com