Suction type emission reduction carrying device for gasoline engine

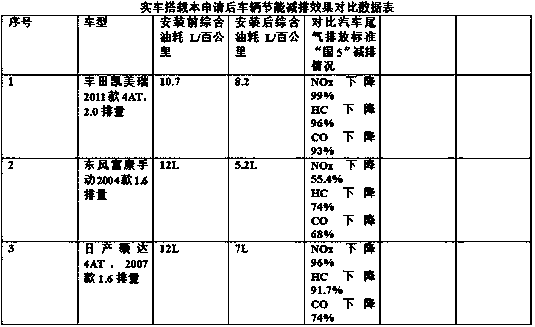

A gasoline engine and oil injection port technology, applied to engine components, machines/engines, charging systems, etc., can solve the problems of unsatisfactory emission reduction effects, large volume, complex structure, etc., and achieve easy installation and maintenance, and small volume , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

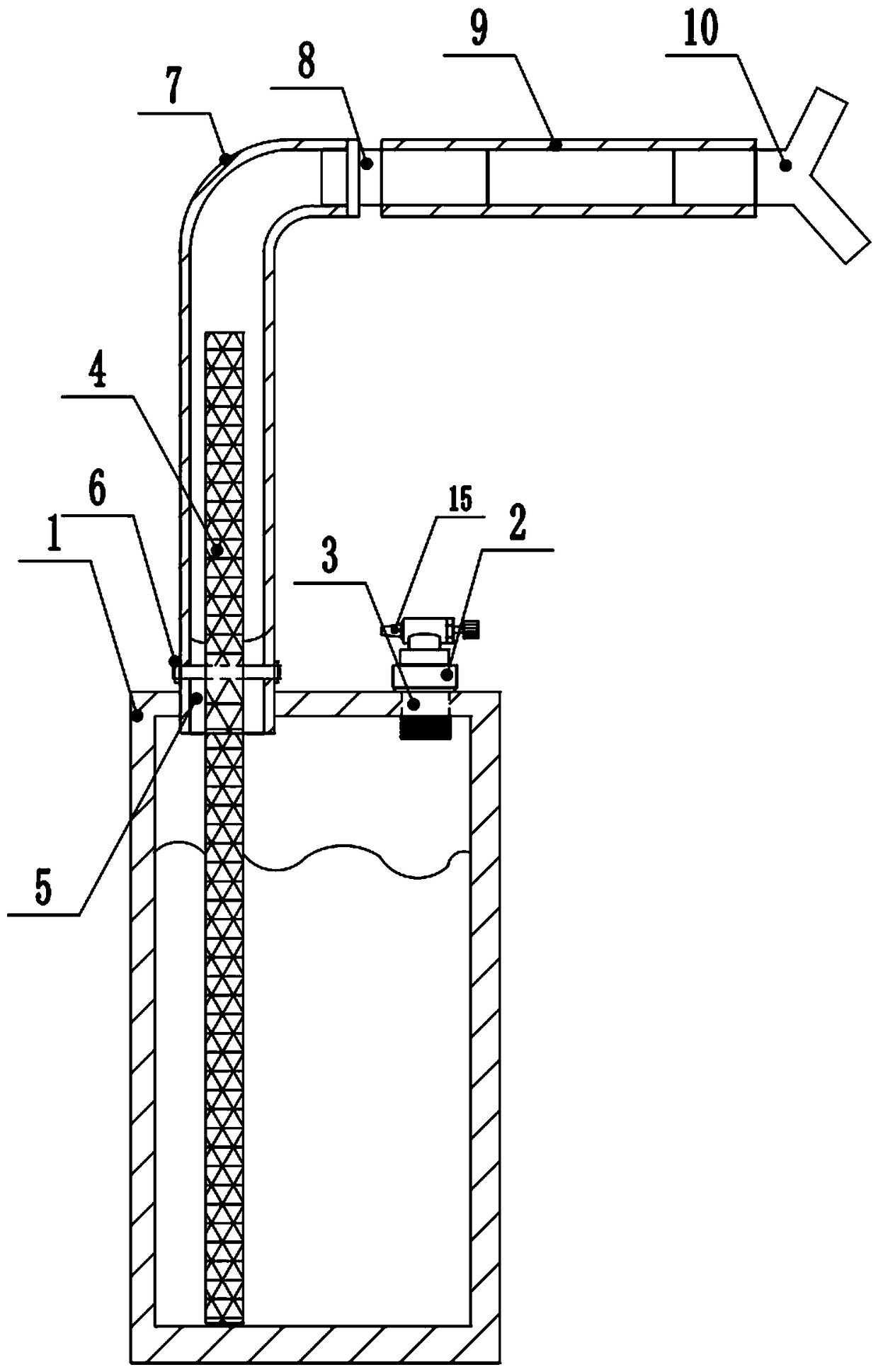

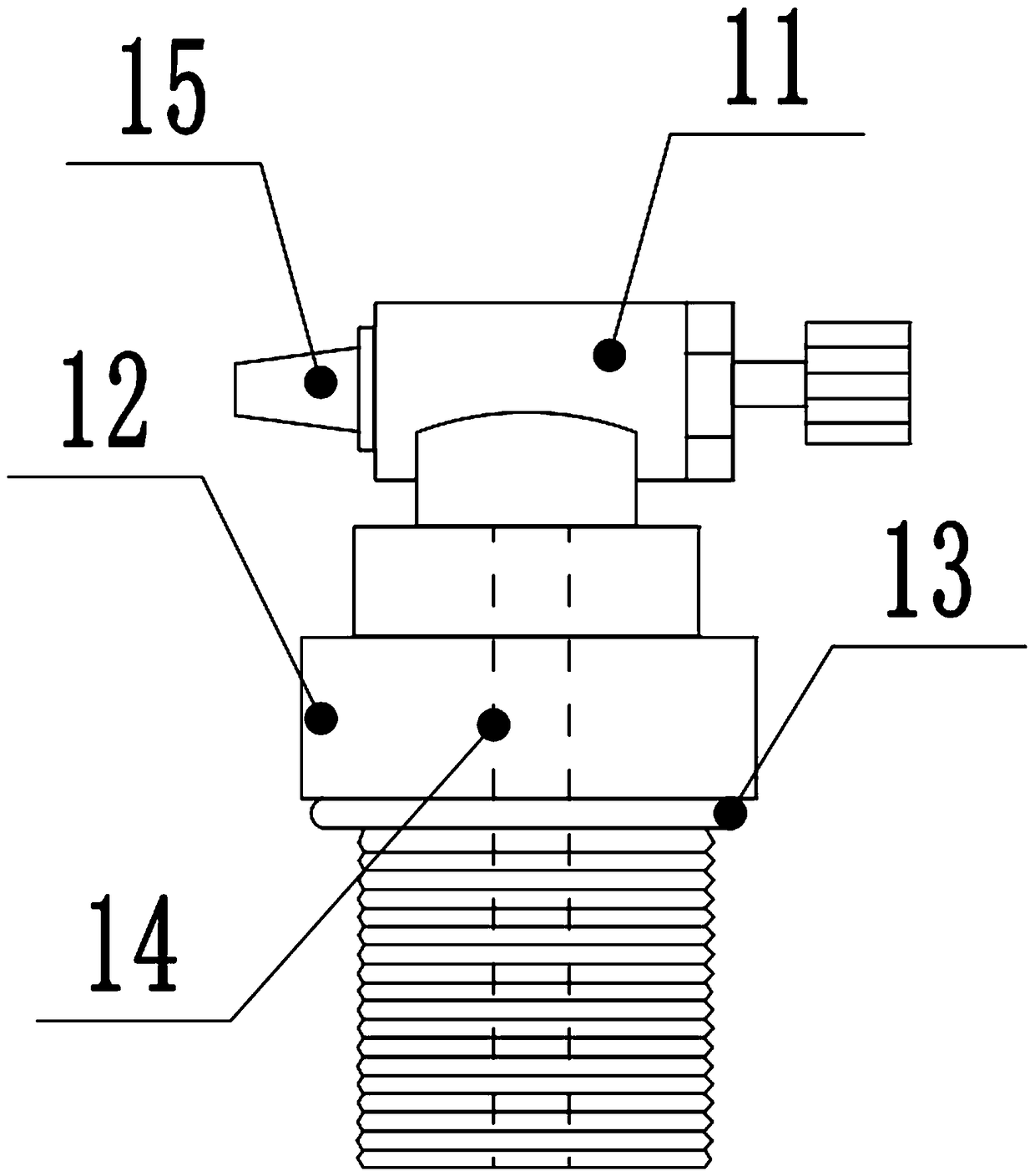

[0032] A suction type emission reduction carrying device for a gasoline engine, comprising: an oil storage tank 1, an oil filling bolt 2, an oil filling port 3, a wick 4, an oil outlet 5, a fixed bolt 6, an observation tube 7, and a conversion joint 8 , an oil outlet pipe 9 and a three-way valve 10, the top of the oil storage tank 1 is provided with an oil injection port 3 and an oil outlet 5, the inner wall of the oil injection port 3 has threads, the oil injection bolt 2 is threadedly connected with the oil injection port 3, and the wick cord 4 Insert the oil storage tank 1 from the oil outlet 5 to the bottom, insert the other end of the wick cord 4 into the observation tube 7, the observation tube 7 is fixedly connected with the oil outlet 5, and the other end of the observation tube 7 is connected to the oil outlet pipe through the conversion joint 8 9, and the other end of the oil outlet pipe 9 is connected with the three-way valve 10.

[0033] The oil filling bolt 2 is c...

Embodiment 2

[0037] A suction type emission reduction carrying device for a gasoline engine, comprising: an oil storage tank 1, an oil filling bolt 2, an oil filling port 3, a wick 4, an oil outlet 5, a fixed bolt 6, an observation tube 7, and a conversion joint 8 , an oil outlet pipe 9 and a three-way valve 10, the top of the oil storage tank 1 is provided with an oil injection port 3 and an oil outlet 5, the inner wall of the oil injection port 3 has threads, the oil injection bolt 2 is threadedly connected with the oil injection port 3, and the wick cord 4 Insert the oil storage tank 1 from the oil outlet 5 to the bottom, insert the other end of the wick cord 4 into the observation tube 7, the observation tube 7 is fixedly connected with the oil outlet 5, and the other end of the observation tube 7 is connected to the oil outlet pipe through the conversion joint 8 9, and the other end of the oil outlet pipe 9 is connected with the three-way valve 10.

[0038] The oil filling bolt 2 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com