Mobile LNG filling trolley

A mobile trolley and mobile technology, applied in the direction of equipment loaded into pressure vessels, fluid treatment, fluid treatment accessories, etc., can solve problems such as economic loss, explosion, easy gasification, etc., to reduce production, save pipeline investment, well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

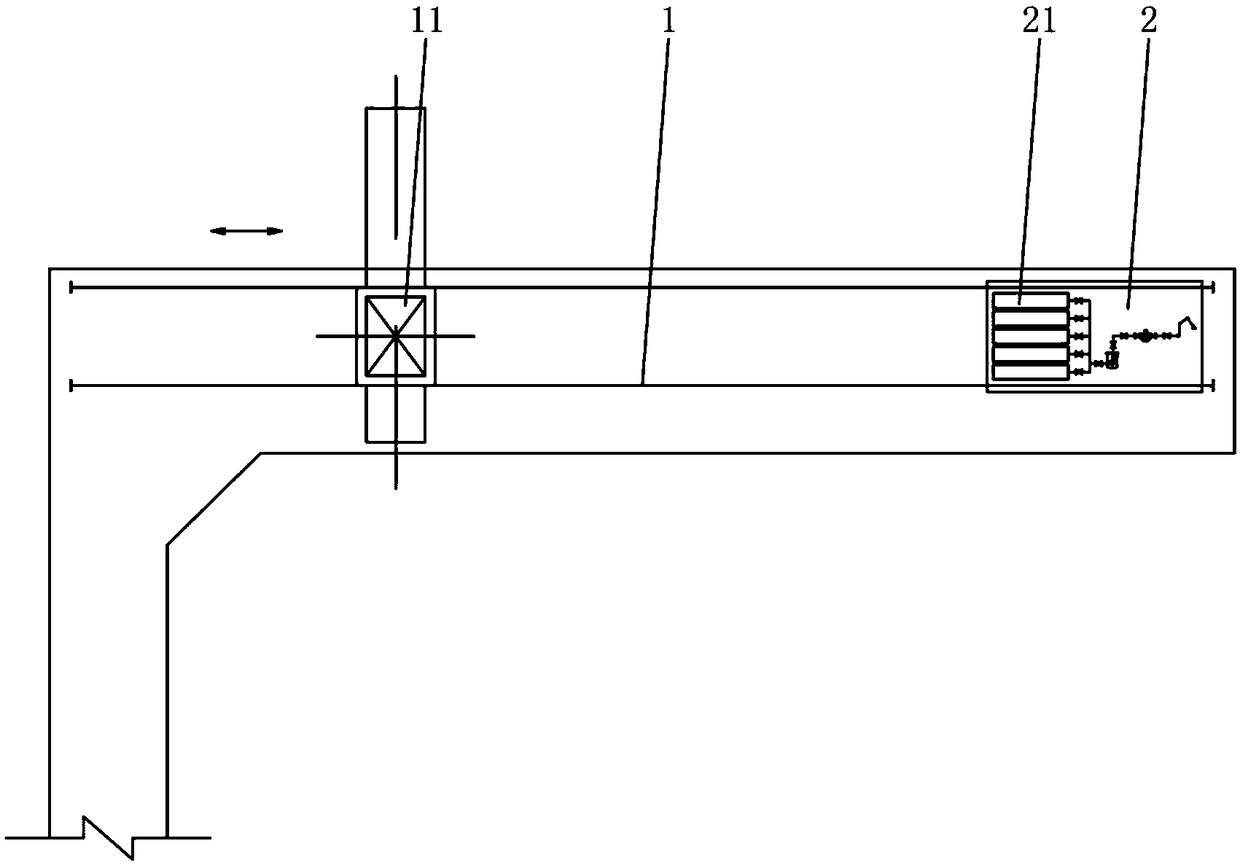

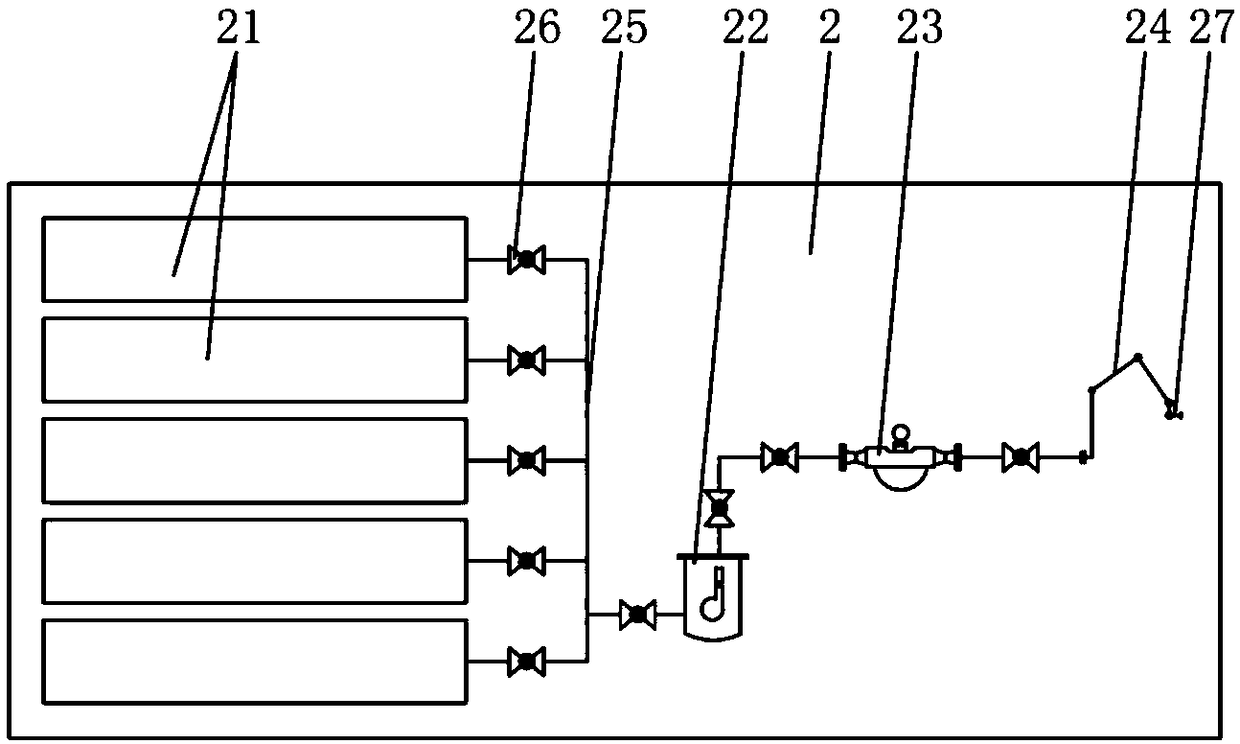

[0018] Such as figure 1 As shown, a mobile LNG filling trolley according to the present invention is provided with a track 1 for the quay bridge 11. The track 1 is provided with a mobile trolley 2 that can move along the track 1, and the mobile trolley 2 is provided with an LNG The filling device; the filling device includes an LNG storage device 21, a filling pump 22, a meter 23 and a loading and unloading arm 24 connected in sequence through a pipeline 25; the mobile trolley 2 can be refitted from a flatbed vehicle, and the The specifications are determined according to the specifications and quantity of the filling device. The mobile trolley 2 can be driven by its own power equipment, or can be moved along the track 1 by using the traction facilities on the wharf; when loading and unloading LNG, the quay bridge 11 is moved to one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com