Vibration amplitude weighted control method based on multiple sensors

A vibration amplitude, multi-sensor technology, used in vibration testing, machine/structural component testing, instruments, etc., can solve problems such as damage to equipment, large displacement errors in acceleration control and control, and achieve less damage, accurate detection, and accurate height detection. The effect of high precision of constant and vibration amplitude control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

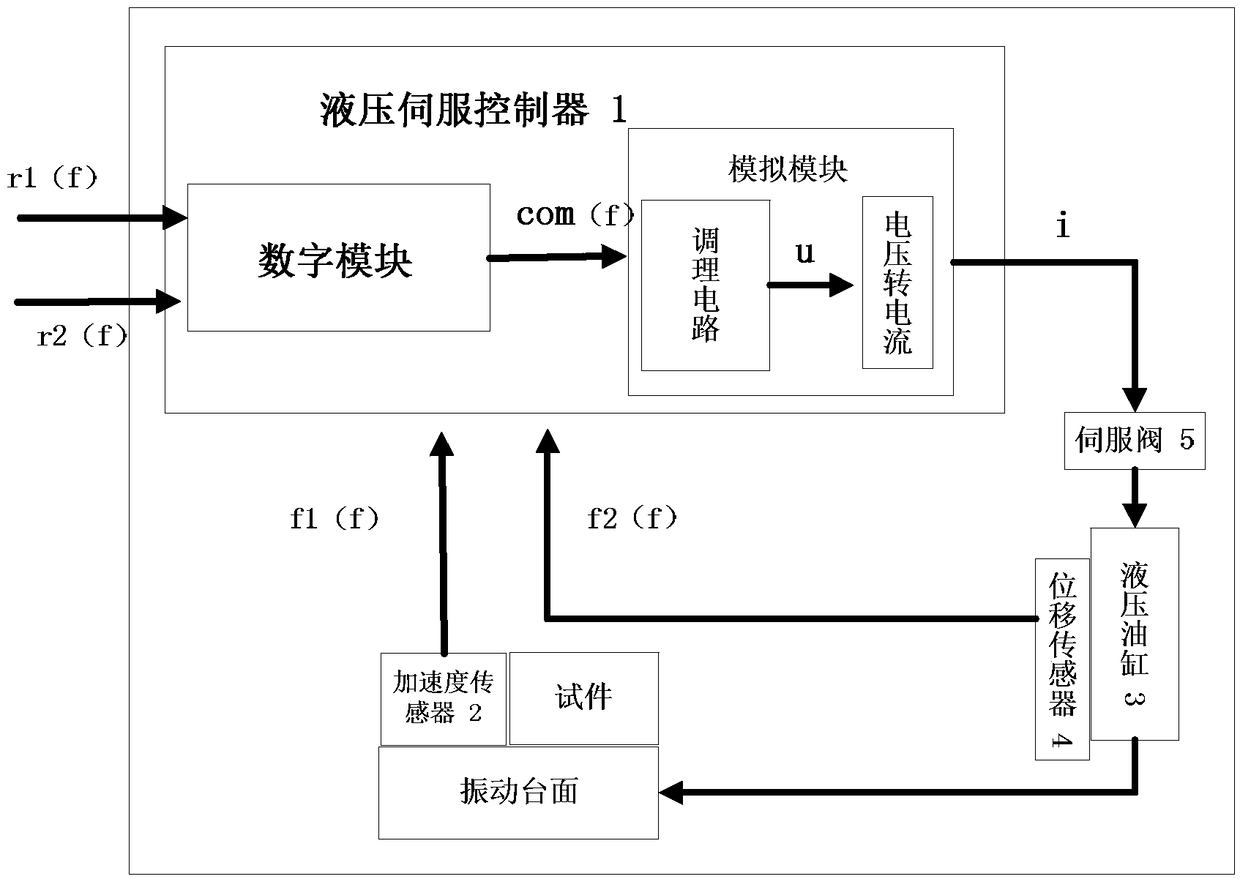

[0033] Such as figure 1 The illustrated embodiment is a vibration amplitude weighted control method based on multiple sensors, including a hydraulic servo controller 1, an acceleration sensor 2 arranged on the vibrating table, a hydraulic cylinder 3, and a displacement sensor 4 arranged on the hydraulic cylinder; The servo controller is electrically connected to the hydraulic cylinder through the servo valve 5, and the hydraulic cylinder is connected to the vibrating table; both the acceleration sensor and the displacement sensor are electrically connected to the hydraulic servo controller; the entire hydraulic system of the present invention corresponds to the material testing machine in the background technology ;

[0034] Including the following steps:

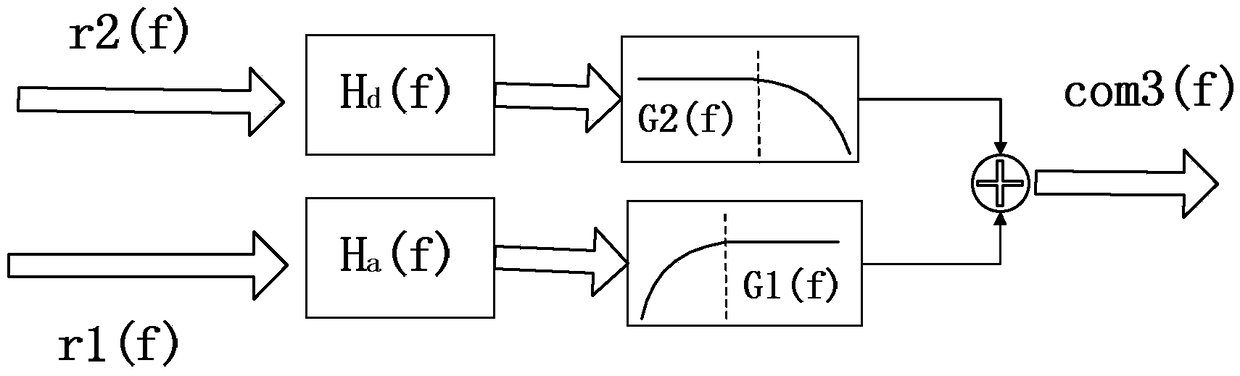

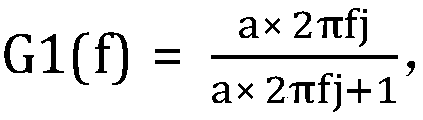

[0035] (1-1) Set the weighting parameter a, f 3 A frequency point in the frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com