Simple device for radially testing low-temperature performance of asphalt mixture

A technology of asphalt mixture and low-temperature performance, which is applied in the direction of measuring devices, applying stable tension/pressure to test material strength, and analyzing materials, which can solve the problems of low test efficiency, cumbersome preparation of test pieces, and low accuracy of test results. Achieve the effects of simplifying the testing process, improving measurement accuracy, and eliminating the process of sticking parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

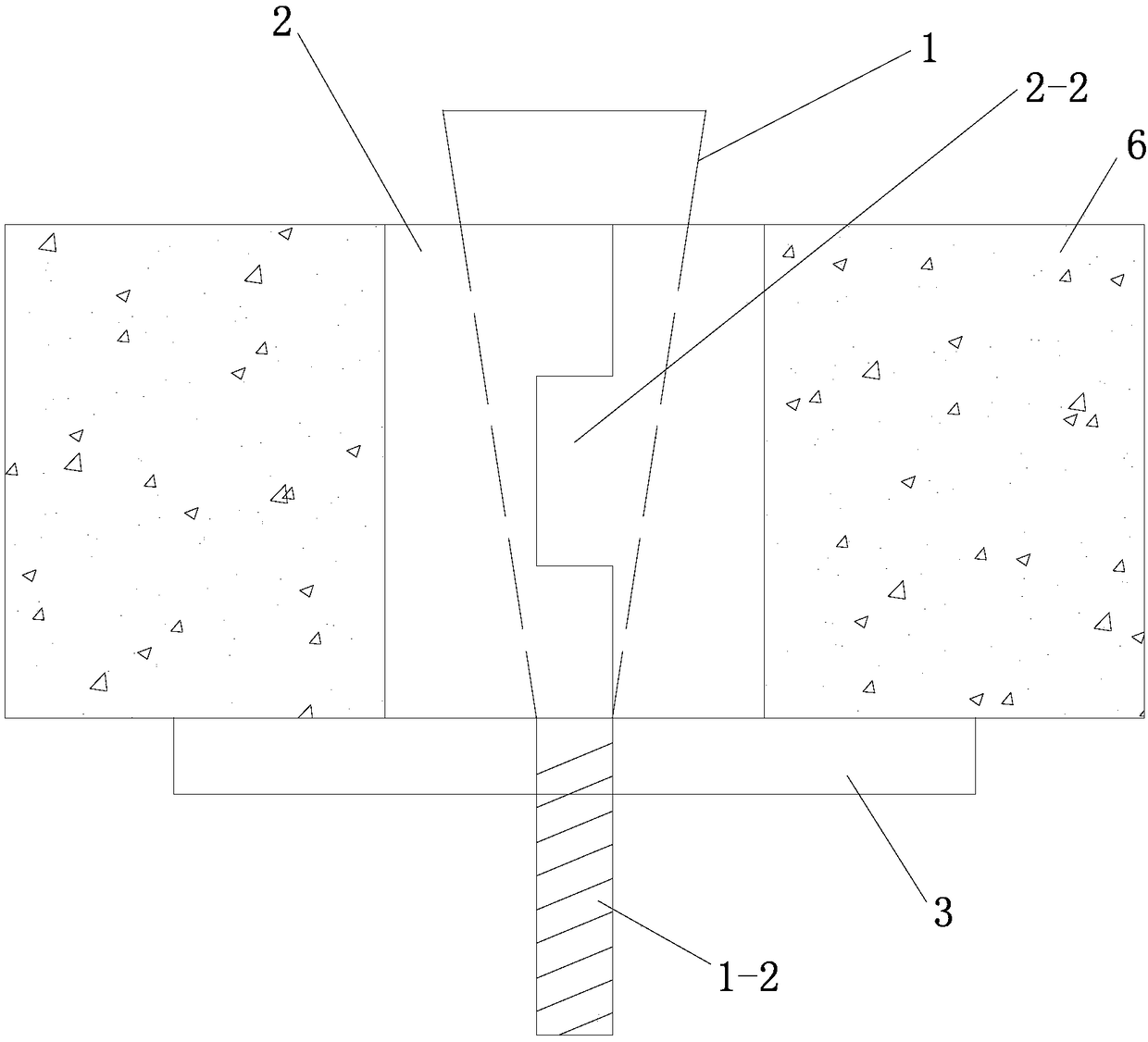

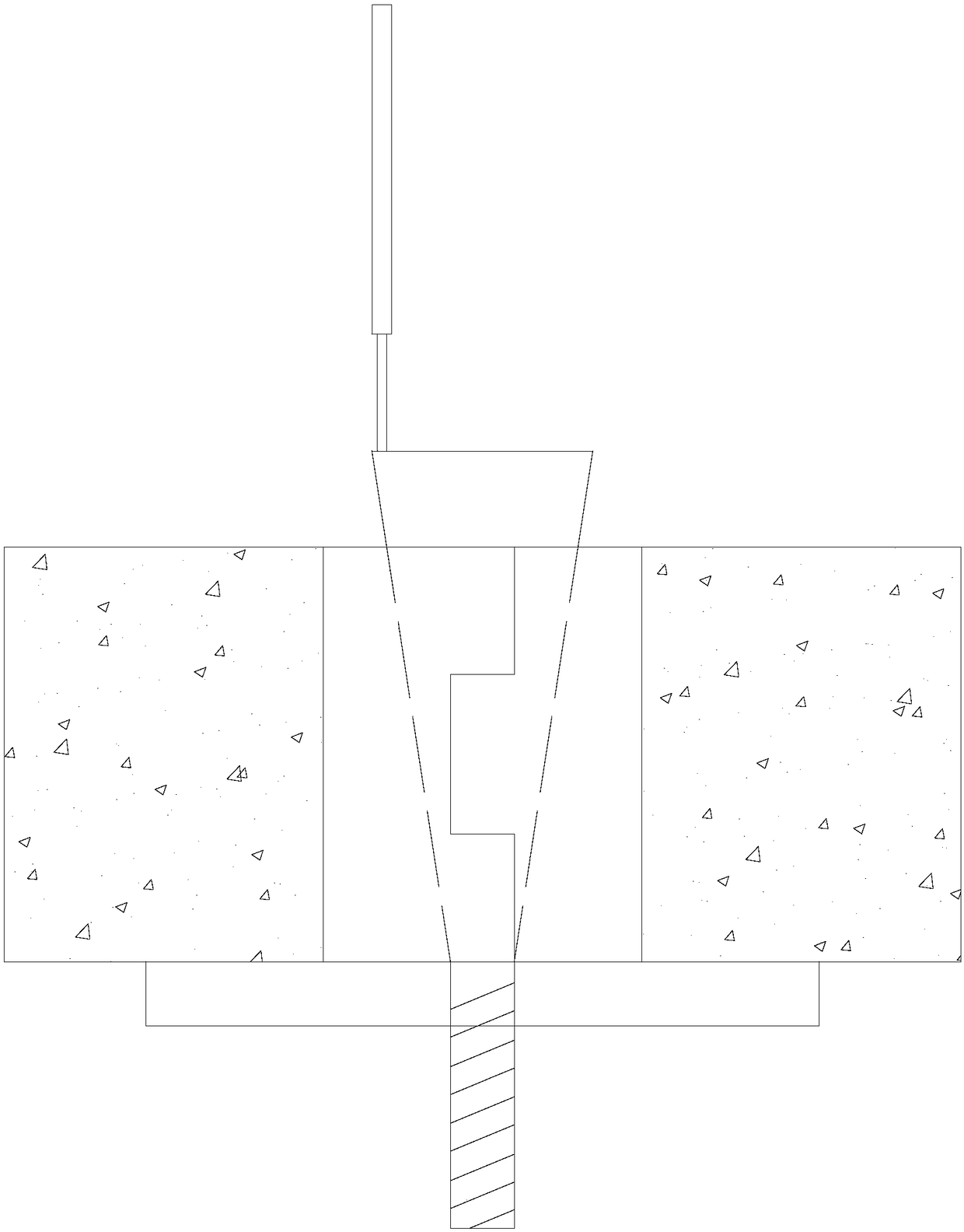

[0031] (1) Low temperature shrinkage test

[0032] The test equipment needs to prepare a circular cylinder specimen, and convert the radial deformation of the specimen into axial deformation through a simple device. The test equipment adopts a rebound type LVDT. The average shrinkage strain and average shrinkage coefficient in the cooling interval are calculated according to formula (1-1) and formula (1-2).

[0033] Δr=Δh·tanθ (1-1)

[0034]

[0035] In the above formula: α——average shrinkage shrinkage coefficient (°C -1 );

[0036] Δr——Annular radius deformation (mm);

[0037] θ——the angle between the conical surface of the conical block and the normal;

[0038] ——The outer diameter of the test piece (mm);

[0039] ——Inner diameter of test piece (mm);

[0040] C——average linear shrinkage coefficient of asphalt mixture;

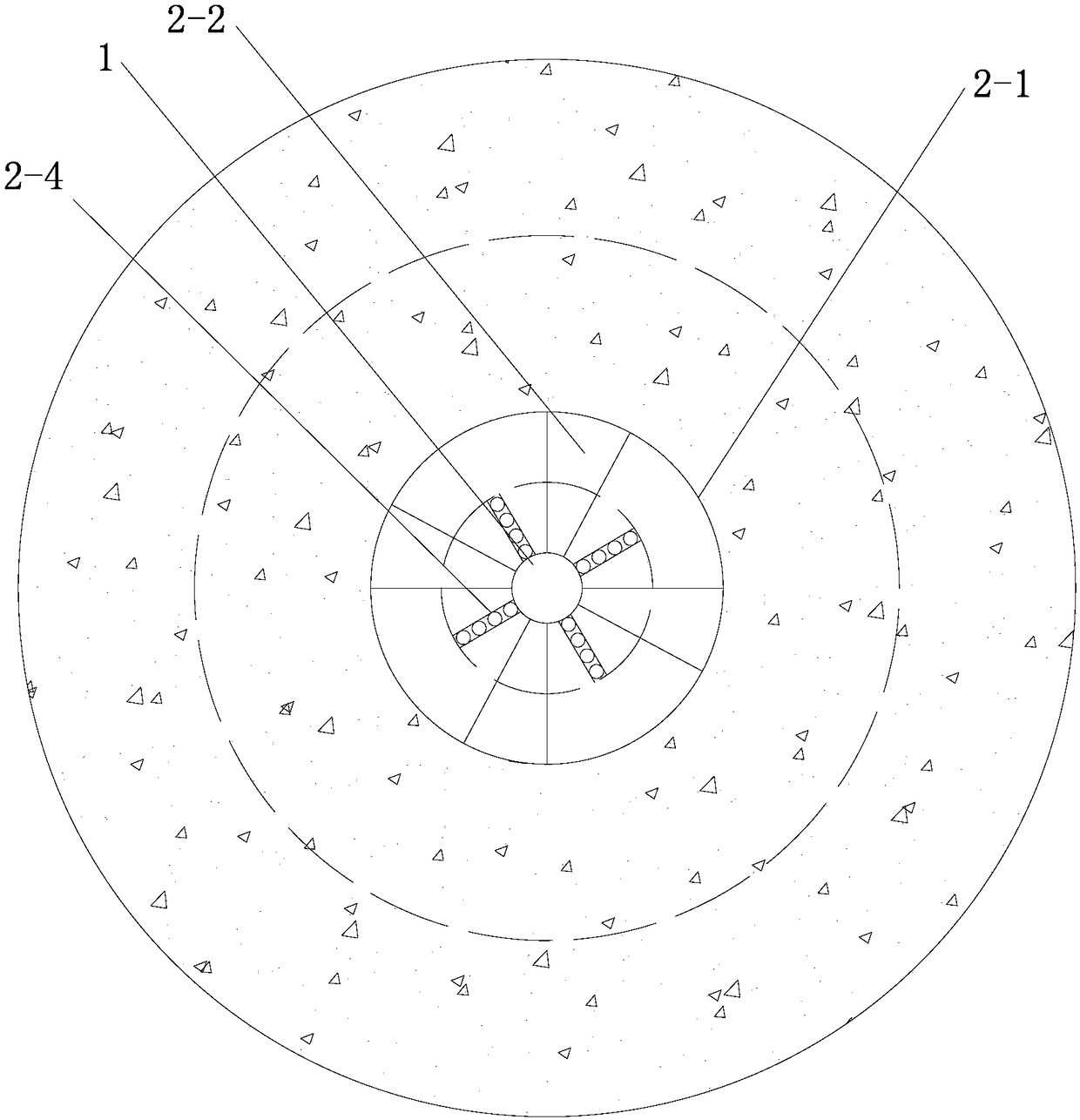

[0041] see image 3 Explanation, example: Prepare standard Marshall specimen 6, obtain a circular cylinder specimen through coring, and carry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com