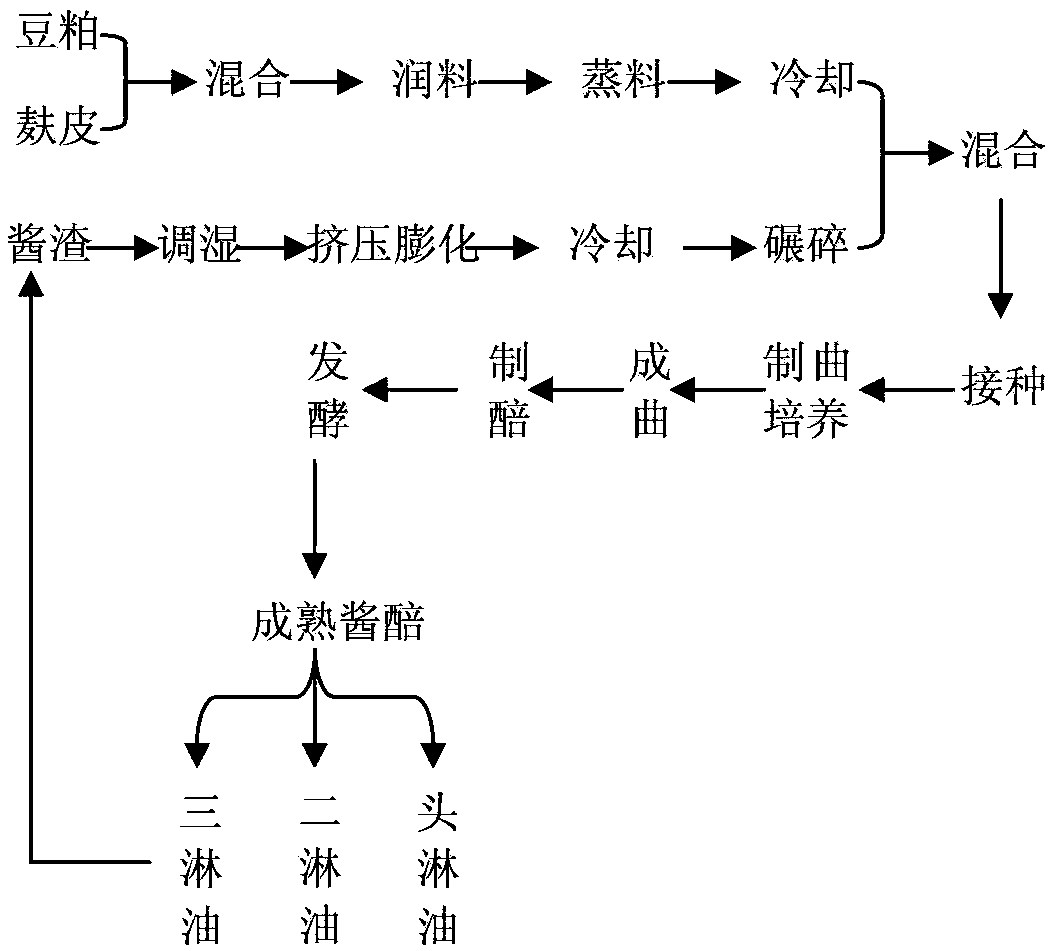

Method for producing soy sauce through extruding and processing sauce residue resources

A technology of extrusion processing and sauce residue, applied in the field of edible condiment production, can solve the problems of environmental pollution, high moisture content and high salt content, and achieve the effects of reducing waste of resources and environmental pollution, and improving yield and utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Weigh 5kg of wet sauce residue, adjust the moisture content of the sauce residue to about 30%, and use a twin-screw extruder to process the sauce residue with an appropriate amount of protease, of which the first section of the sleeve, the second section of the sleeve and the third section of the sleeve The barrel temperature is 30°C, 60°C and 90°C respectively, the screw speed is 150rpm, and the extruded sauce dregs are crushed for later use;

[0019] 2. Weigh 15kg of soy sauce brewing raw materials (soybean meal: bran=6:4), carry out steaming and processing according to the existing traditional technology, and mix evenly with the sauce dregs after the extrusion processing after cooling;

[0020] 3. The above-mentioned mixture is subjected to moistening treatment, and the amount of water added is 85% based on the amount of soybean meal;

[0021] 4. Insert the above-mentioned materials into Aspergillus oryzae or Aspergillus sojae, and cultivate microorganisms under s...

Embodiment 2

[0027] Weigh 5kg of wet sauce residue, adjust the moisture content of the sauce residue to about 60%, and use a twin-screw extruder to process the sauce residue without adding enzymes, wherein the temperature of the first sleeve, the second sleeve and the third sleeve 60°C, 120°C and 190°C respectively, the screw speed is 150rpm, and the extruded sauce dregs are crushed for later use;

[0028] All the other operations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com