Preparation method of wheat germ-based puffed food

A technology of wheat germ and puffed food, which is applied in food preservation, food ingredients, food ingredients as antioxidants, etc., can solve the problems of shortening the shelf life of products and reducing the nutritional value of germ, so as to broaden the utilization channels, improve retention, reduce Waste of resources and effects of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

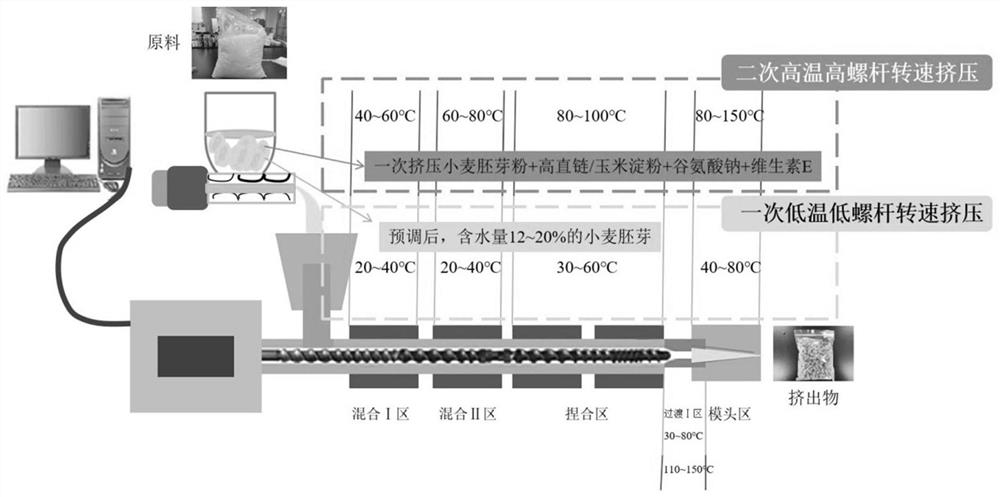

[0026]Method for preparing wheat germ base expanded food, steps are as follows:

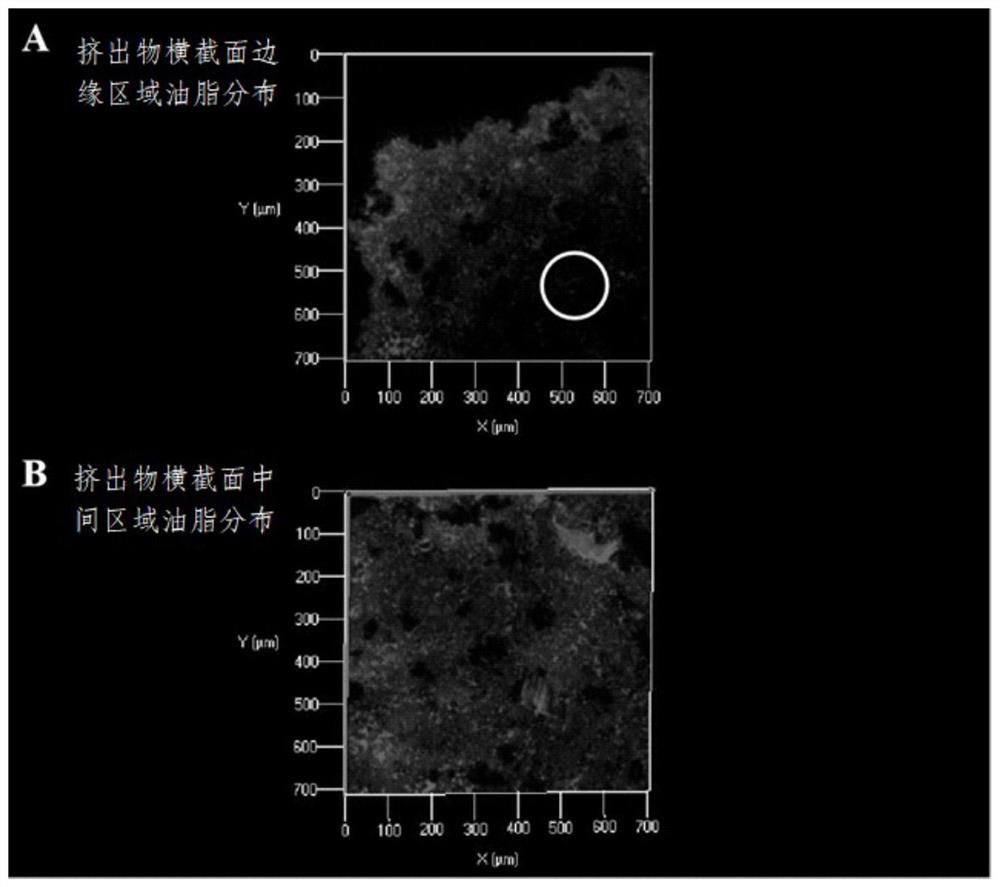

[0027](1) Adjust the water content of unpatomy wheat germs to 12%, such asfigure 1 The low temperature and low screw speed extrusion is performed, wherein the mixed I region temperature is 20 ° C, the mixing II region temperature is 20 ° C, the kneading region temperature is 30 ° C, the transition zone temperature is 30 ° C, the screw speed is 50 rpm, load The ratio is 2, the mode temperature is 40 ° C; after a squeezing, the wheat germ extrudate is obtained; the cross section of wheat embryo extrudate is scanned with a laser confocal microscope, such asfigure 2As shown, the grease is more than the cross section, the centrally distributed mode, and the oil is uniformly distributed in the intermediate region of the extrudate; tested, the crude oil retention (mass percent) is 85.86%.

[0028](2) A starch of 19% by 19% and a step (1) obtained by extruding wheat germ in 4: 6 parts by weight, add 0.02 parts by we...

Embodiment 2

[0040](1) Adjuding the unpatomy wheat germ moisture content to 20%, performing a low temperature and low screw speed squeezing, wherein the mixed I region temperature is 40 ° C, the mixed II region temperature is 40 ° C, the kneading region temperature is 60 ° C, transition The I region temperature is 80 ° C, the screw speed is 200 rpm, the load ratio is 10, the die region temperature is 80 ° C; after one extrusion, the wheat germ extrudate; scanning the wheat embryo extrudate with a laser confocal microscope In the cross section, the oil exhibits an edge in the cross section, and the centrally distributed mode is a uniform distribution in the middle area of the extrudate; it is tested, the crude oil retention degree (mass percent) is 88.06%;

[0041](2) A starch with a branching degree of 18% and a step (1) obtained by an extrusion wheat germ in 6: 5 parts by weight, add 0.015 parts by weight of vitamin E and 0.025 parts by weight of glutamate sodium. , Mixed, the mixed material was...

Embodiment 3

[0053](1) Regulate the unpretty wheat germ moisture content to 15%, performing a low temperature and low screw speed squeezing, wherein the mixed I region temperature is 30 ° C, the mixed II region temperature is 30 ° C, the kneading region temperature is 40 ° C, transition The temperature of the I zone is 60 ° C, the screw speed is 100 rpm, the load ratio is 5, the die region temperature is: 60 ° C; once squeezed, the wheat germ extrudate is obtained; the wheat germ extrudate is scanned with a laser confocal microscope. The cross section, the oil is in the cross section, and the centrally distributed mode is present, and the oil is uniformly distributed in the middle area of the extrudate; the crude oil retention (mass percent) is 89.74%;

[0054](2) A starch with a branching degree of 17% and a step of extrusion of wheat germ obtained by step (1) Press 5: 5 parts by weight, add 0.01 parts by weight of vitamin E and 0.02 parts by weight of glutamate sodium. , Mixed, mixing the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com