Furniture material

A furniture and solder technology, applied in bridge materials, tunnel linings, rigid pipes, etc., can solve the problems of no heat preservation, fire prevention, sound insulation, vibration isolation, large overall weight, poor sound insulation effect, etc., to achieve light weight, overall The structure is stable and the effect of improving the sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

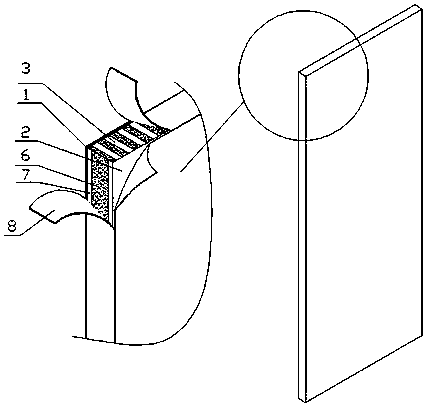

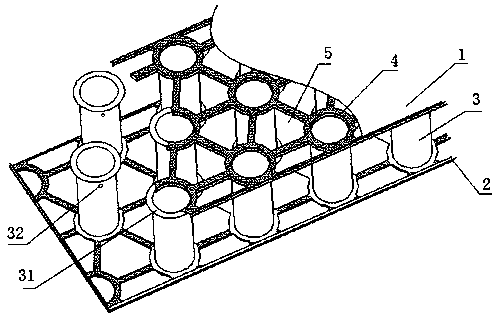

[0041] Such as figure 1 with figure 2Shown: a door body, made of a metal plate, the metal plate includes the first panel 1, the second panel 2, several hollow tubes 3 in the middle, and the space between the hollow tube 3 and the first panel 1, the second panel 2 For the brazing layer, the upper and lower ends of the hollow tube 3 are provided with flanging 31, turning out a circular structure. The flange 31 of the hollow tube 3 is connected to the first panel 1 and the second panel 2 by soldering 4 .

[0042] The cross section of the hollow tube is circular, and the hollow tube is a cylindrical tube. The hollow tubes are arranged at intervals, and after the arrangement, the brazing layer is formed on the flange by the brazing material. The brazing filler metal 4 is punched and flanged, and this flanging is to turn down along the hole of the brazing filler metal, so that the hollow tube 3 is enclosed within the location on the flanging of the brazing filler metal 4.

[00...

Embodiment 2

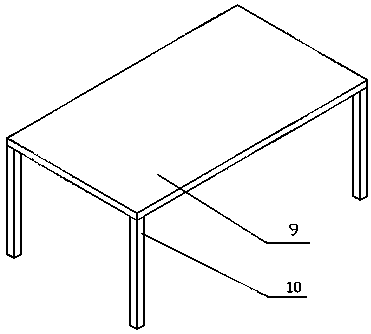

[0052] Such as image 3 Shown: a coffee table, including a table top 9 and legs 10, the table top 9 is made of a metal plate, the structure of the metal plate is the same as in Embodiment 1, and will not be repeated here.

[0053] The metal plate of the platform 9 and the legs 10 are connected by bolts.

Embodiment 3

[0055] Such as Figure 4 Shown: a wardrobe, including a cabinet body 11, a partition 12 is arranged inside the cabinet body 11, wherein both the cabinet body 11 and the partition 12 adopt the metal plate structure of the first embodiment. Multiple metal plates are connected by multiple bolts to form a cabinet structure. The dividing plate 12 is divided into a horizontal dividing plate and a vertical dividing plate, and the vertical dividing plate is connected by bolts between the inwall of the cabinet body 11; the horizontal dividing plate is also connected by bolts between the cabinet body 11 and the vertical dividing plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com