Device for treating salt-containing water by self-condensation and multi-stage cross-circulation of desalination substance and humidification and dehumidification of air

A water treatment device and cross-circulation technology, which is applied in the field of salt water treatment, can solve the problems of high device, inconvenient series operation, fresh water leakage, etc., and achieve the effects of long service life, small footprint and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

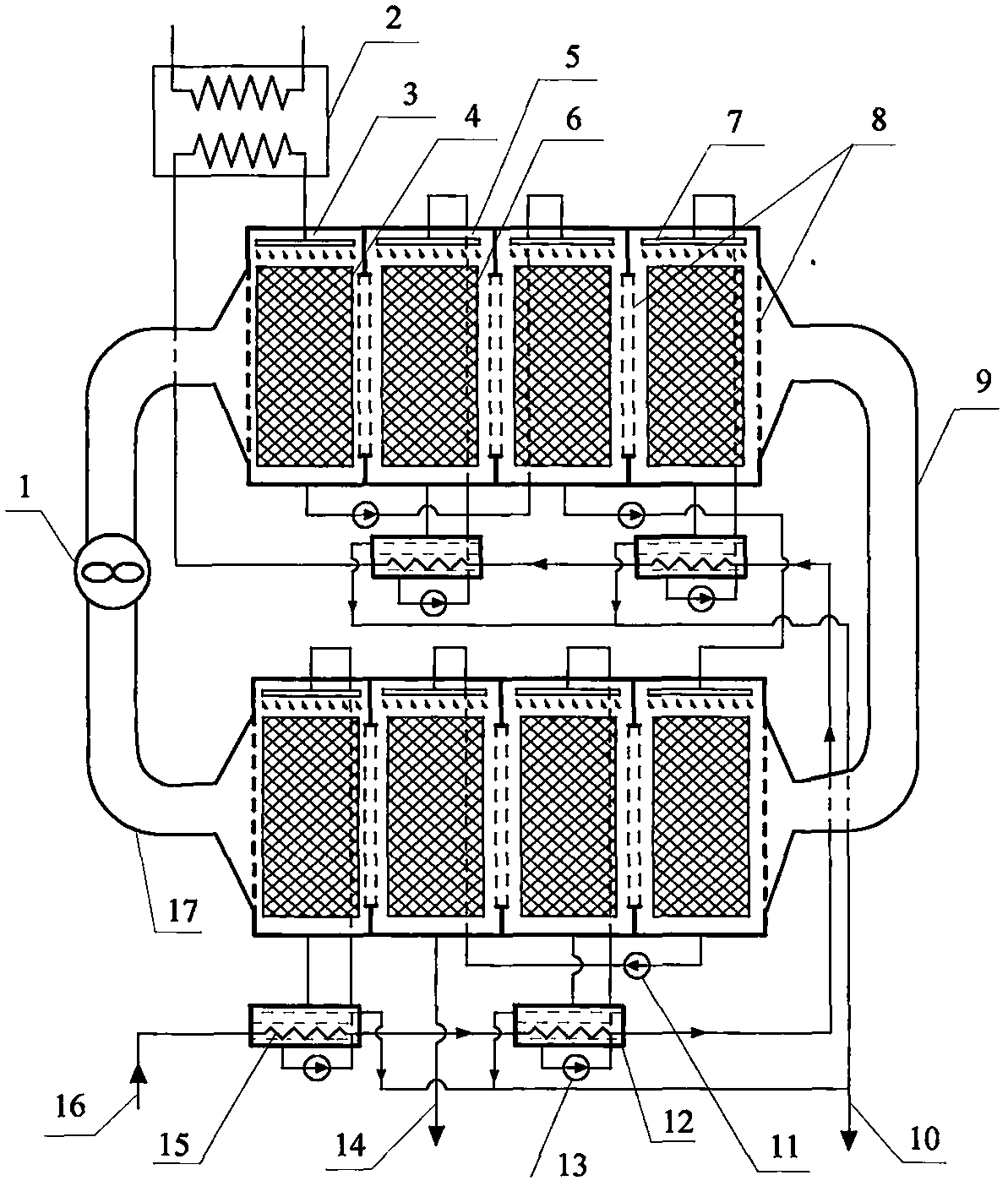

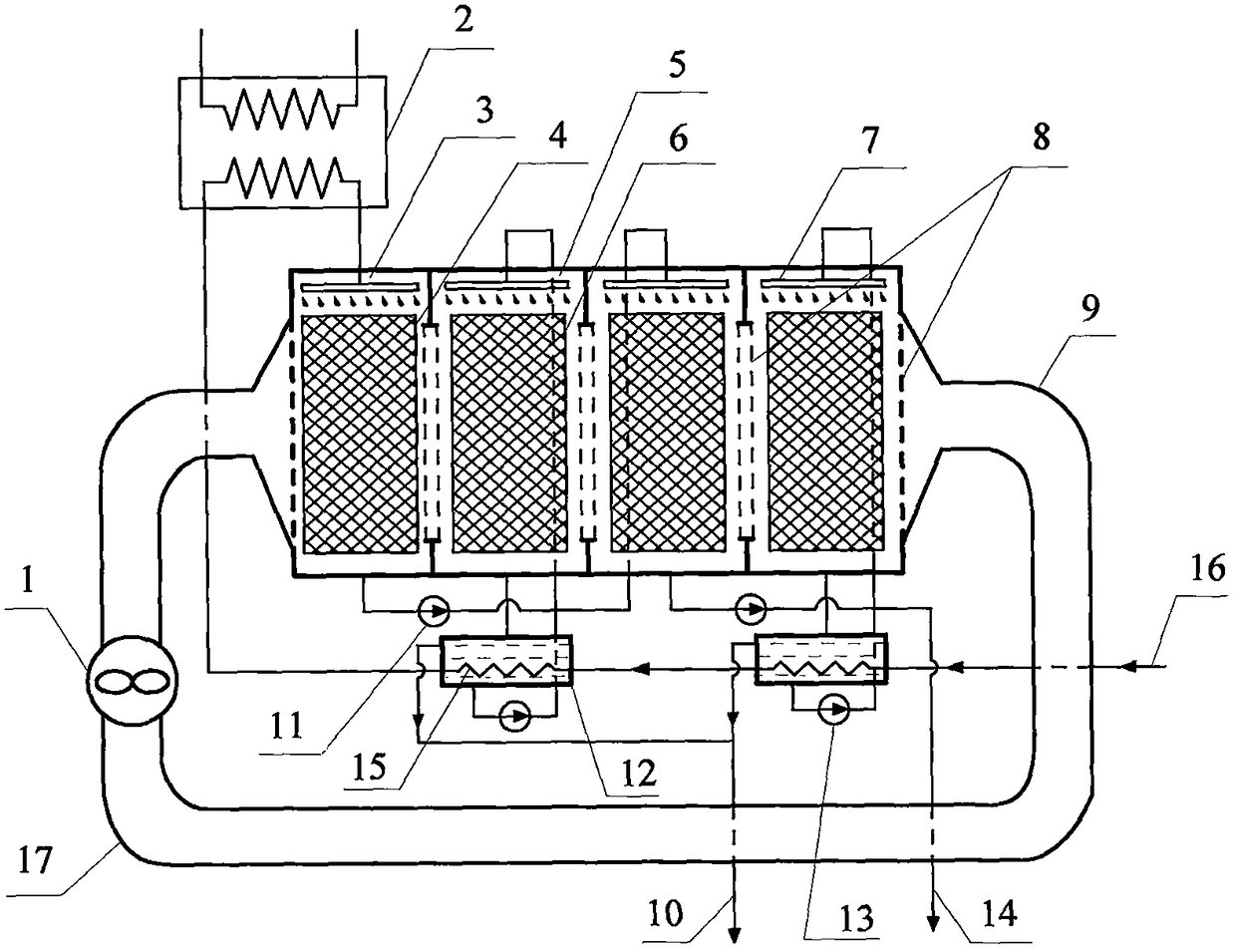

[0026] Below in conjunction with accompanying drawing real and give examples

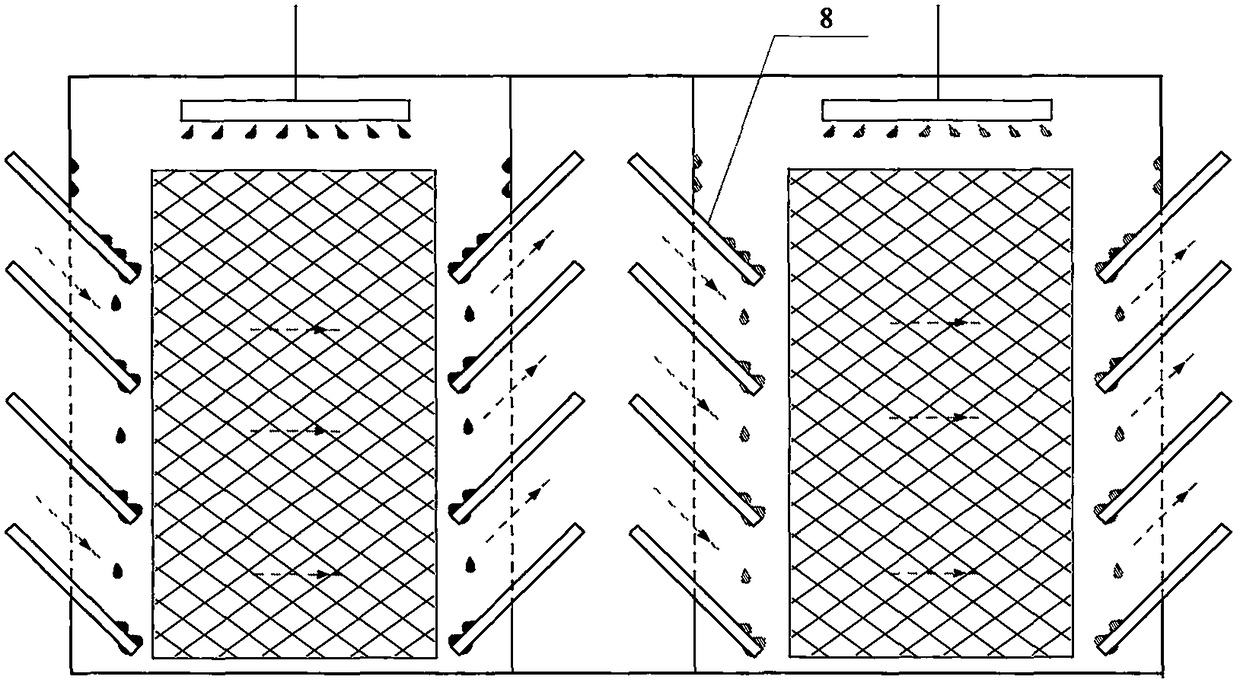

[0027] The present invention provides a self-condensing multi-stage cross-circulation air humidification and dehumidification salt water treatment device for desalinated matter, and its internal main devices include: fan 1, heat source water tank 2, humidification filler 4, dehumidification filler 6, liquid distributor 7, foam catcher 8. Air return pipe 9, brine circulating water pump 11, fresh water cooling tank 12, fresh water circulating water pump 13, cooling coil 15, main air duct 17.

[0028] Wherein the fan 1 sends the circulating air laterally into the humidification chamber through the single-layer mist catcher 8 . The liquid distributor 7 is located above the interior of the humidification chamber, and the feed containing brine passes through the external heat source water tank 2 and then is sprayed by the liquid distributor 7 and flows into the humidification filler 4 below. The circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com