High-precision vibration-resistant Pirani vacuum sensor

A vacuum sensor and temperature sensor technology, applied in vacuum gauges, instruments, measuring devices, etc., can solve the problems of low measurement accuracy, low stability and anti-vibration, and achieve high measurement accuracy, stable filament temperature, and improved measurement resolution. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

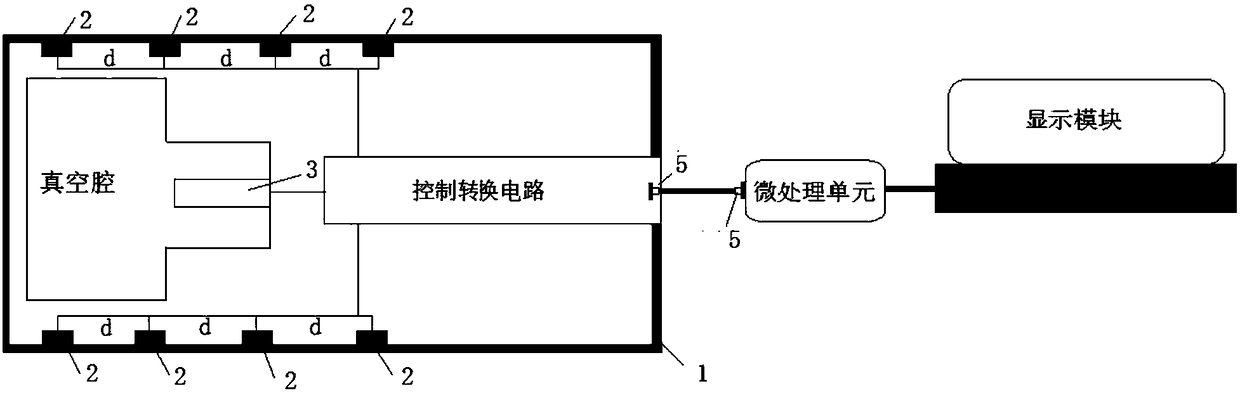

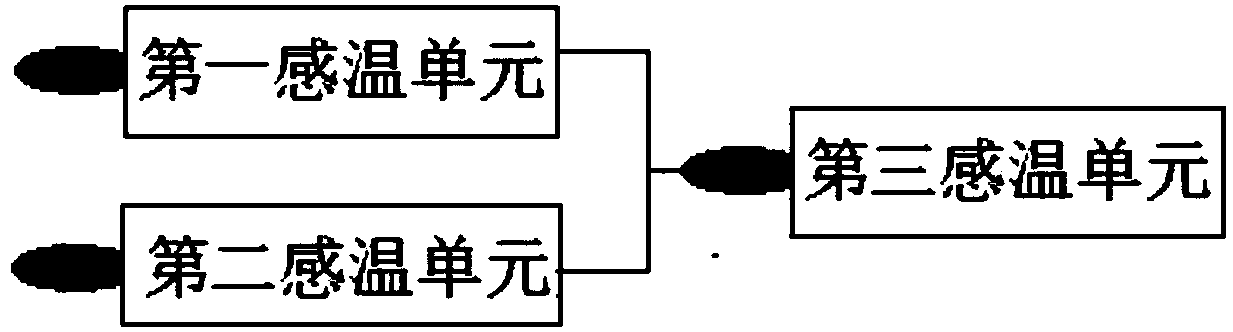

[0036] This embodiment provides a high-precision anti-seismic Pirani vacuum sensor, the high-precision anti-seismic Pirani vacuum sensor includes a temperature sensing module and a control module, the temperature sensing module includes a metal shell, and the metal shell is provided with a vacuum chamber, a temperature sensing device is provided in the vacuum chamber, and a control conversion circuit connected to the induction device, the control conversion circuit includes a signal amplification circuit and an AD conversion circuit; the control module includes a micro-processing unit connected to the control conversion circuit, and The display module to which the processing unit is connected. Such as image 3 , the temperature sensing device includes 3 temperature sensing units, through the parallel connection of the first temperature sensing unit and the second temperature sensing unit, the structure of the third temperature sensing unit connected in series with the first te...

Embodiment 2

[0047] On the basis of Embodiment 1, this embodiment further optimizes usage scenarios. In this embodiment, one control module corresponds to multiple temperature sensing modules, which can improve the utilization rate of the control modules, thereby reducing costs.

[0048] Such as Image 6 , the control module and the temperature-sensing module are connected by a signal cable, and the one control module corresponds to N temperature-sensing modules; wherein N is a positive integer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com