Full-automatic unattended grain assay system

A fully automatic, food technology, applied in the direction of testing food, material inspection products, chemical instruments and methods, etc., can solve the problems of inability to eliminate human food, inability to ensure the authenticity and representativeness of samples, and lack of laboratory parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

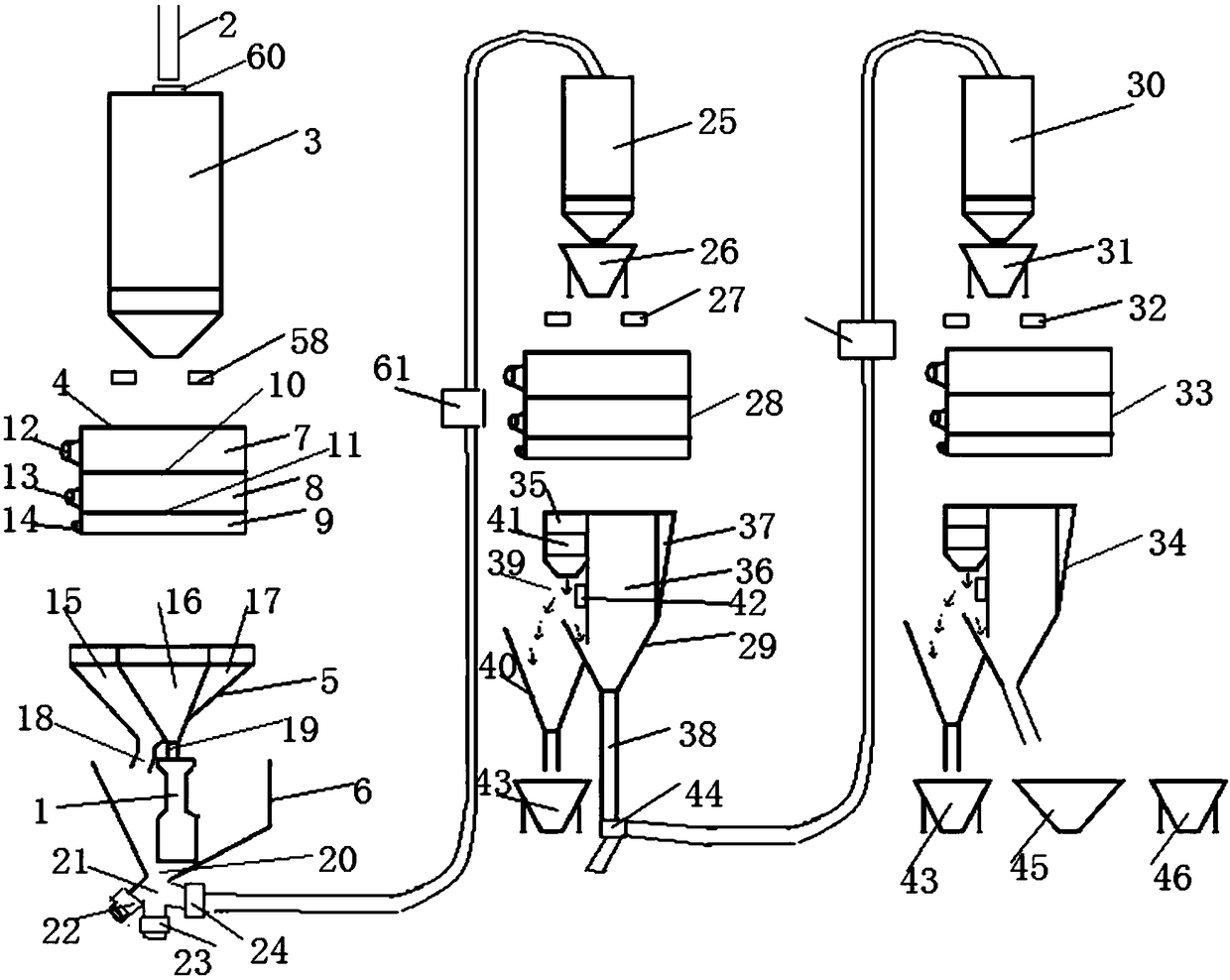

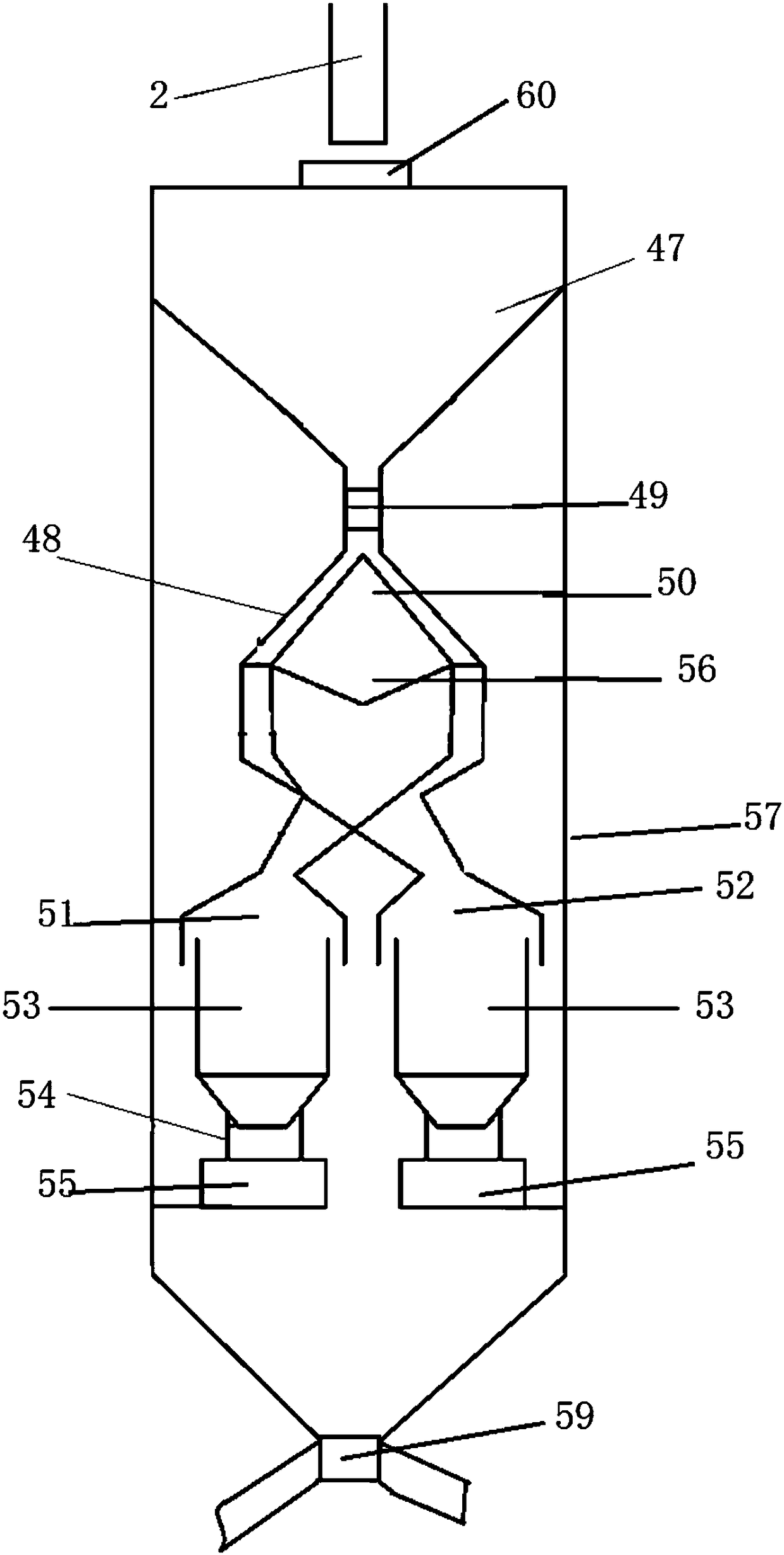

[0022] like figure 1 As shown, a fully automatic unattended grain testing system described in this embodiment includes a computer, a PLC, a sample delivery unit, a sampling unit, a sampling packaging unit, a two-dimensional code management unit, an alarm unit, and a bulk density moisture detection unit. Unit 1 and the automatic detection and extraction unit of impurity imperfect grains, the PLC and the bulk density and moisture detection unit 1 are all connected to the computer;

[0023] The sample conveying unit comprises a conveying pipe 2, which is provided with a first vacuum pump and a signal line which are all connected to the PLC, and one end of the conveying pipe 2 is connected with the sampling unit, and the other end is connected with the top of the sample rod of the cutting machine. connected, the computer can monitor whether the conveying pipe 2 is disconnected according to whether the signal line is disconnected, that is, whether the conveying pipe 2 is separated ...

Embodiment 2

[0035] This embodiment is the same as other places in Embodiment 1, and the difference is that the height of the packing port 20 is higher than the height of the second sample divider 25, and the height of the sample divider 38 of the second funnel 29 is higher than the third divider. The height of the device 30 is such that the sample can travel by gravity in the sample dividing unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com