Lithium battery cathode sheet and preparation method thereof, all-solid-state lithium battery and pre-solid-state lithium battery

A positive electrode, lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low chemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] In the present invention, the preparation method of the solid electrolyte sheet can be a variety of conventional solid electrolyte sheet preparation methods in the art, for example, it can include: uniformly mixing the sulfide solid electrolyte and the binder in the first organic solvent to form a slurry, Then the slurry is evenly coated on the polyester film, then dried at 80-85° C., cut into discs with a diameter of 13.0-15.0 mm and peeled off from the polyester film to obtain a solid electrolyte sheet. Wherein, the homogeneous mixing method may use a vacuum mixer to stir to achieve the purpose of uniform mixing. Wherein, the stirring speed may be 100-1500rmp, and the stirring time may be 1-48h.

[0059] According to the all-solid-state lithium battery of the present invention, the negative electrode sheet can be any conventional lithium ion battery negative electrode sheet in the art, for example, it can be metal lithium or lithium-indium alloy.

[0060] In the pres...

Embodiment 1

[0070] This example is used to illustrate the positive electrode sheet of the lithium battery and its preparation method and the all-solid lithium battery of the present invention.

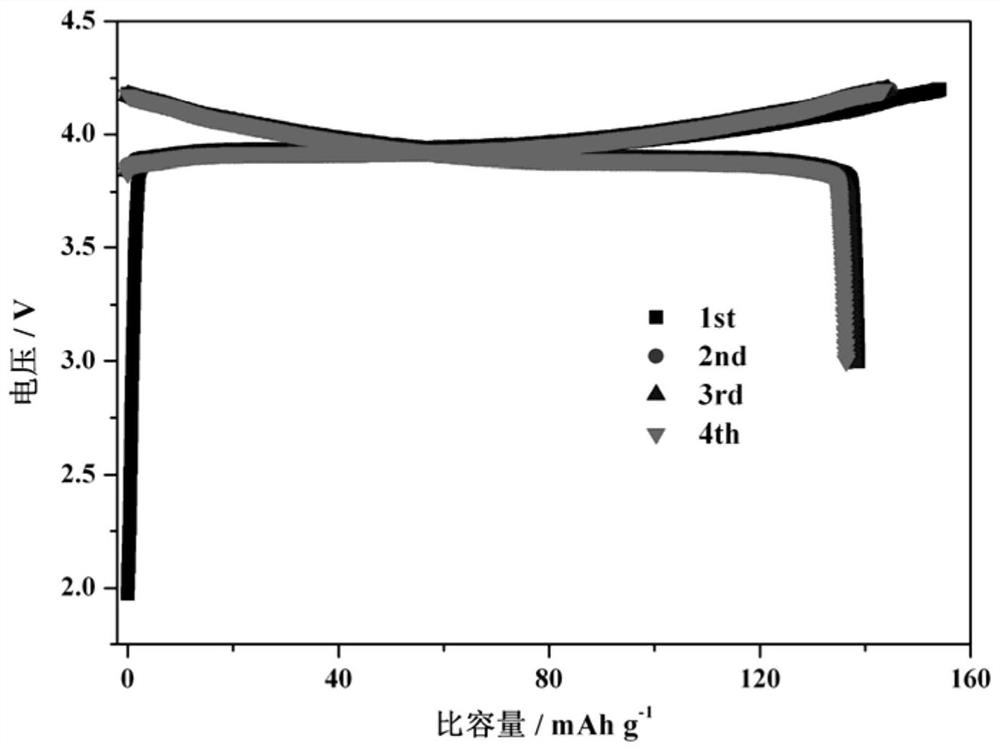

[0071] (1) Preparation of positive electrode sheet for lithium battery

[0072] The cathode active material (LiCoO 2 )6.0mg, sulfide solid electrolyte (crystalline Li 10 GeP 2 S 12 ) 3mg, conductive agent (acetylene black) 0.7mg and binder (styrene-butadiene rubber SBR) 0.3mg are mixed uniformly in anhydrous toluene to form a stable and uniform slurry, wherein the stirring speed is 1000rmp, and the time is 12h; then Coat the obtained slurry on the current collector aluminum sheet, then dry it at 80°C, and then cut it into a disc with a diameter of 13.0mm; then use the obtained disc as the positive electrode sheet, and use metal lithium as the negative electrode sheet, and 3mol / L LiN(CF 3 SO 2 ) 2 , 2 wt% Li 2 S 6 An additive solution composed of an ether organic solvent is used as an elec...

Embodiment 2

[0078] This example is used to illustrate the positive electrode sheet of the lithium battery and its preparation method and the all-solid lithium battery of the present invention.

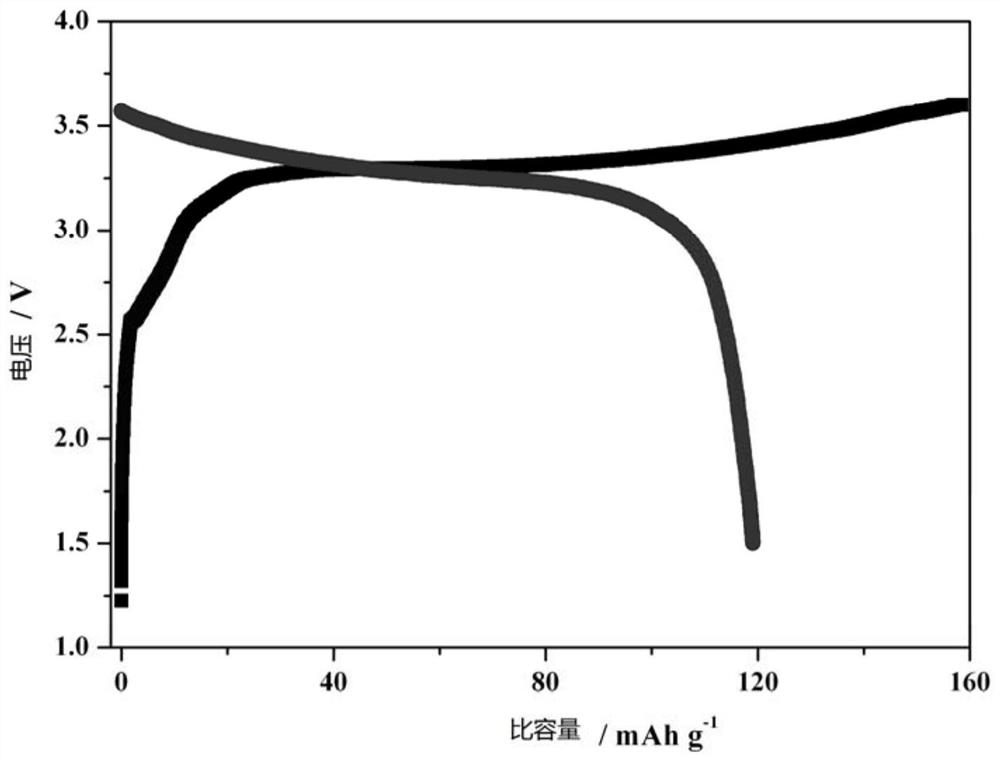

[0079] (1) Preparation of positive electrode sheet for lithium battery

[0080] The cathode active material (LiFePO 4 )6.0mg, sulfide solid electrolyte (crystalline Li 10 SnP 2 S 12 ) 1.5mg, conductive agent (carbon nanotube) 1.2mg and binding agent (styrene-butadiene rubber SBR) 0.12mg are mixed uniformly in anhydrous xylene to form stable uniform slurry, wherein, the stirring speed is 1500rmp, and the time is 1h; then coat the obtained slurry on the aluminum sheet of the current collector, then dry it at 85°C, and then cut it into a disc with a diameter of 14.0mm; then use the obtained disc as a positive electrode sheet, and use metal lithium as a negative electrode sheet, and will be made of 4mol / L LiCF 3 SO 3 , 5 wt% Li 2 S 2 An additive solution composed of an ether organic solvent is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com