Activated carbon deodorant and preparation method

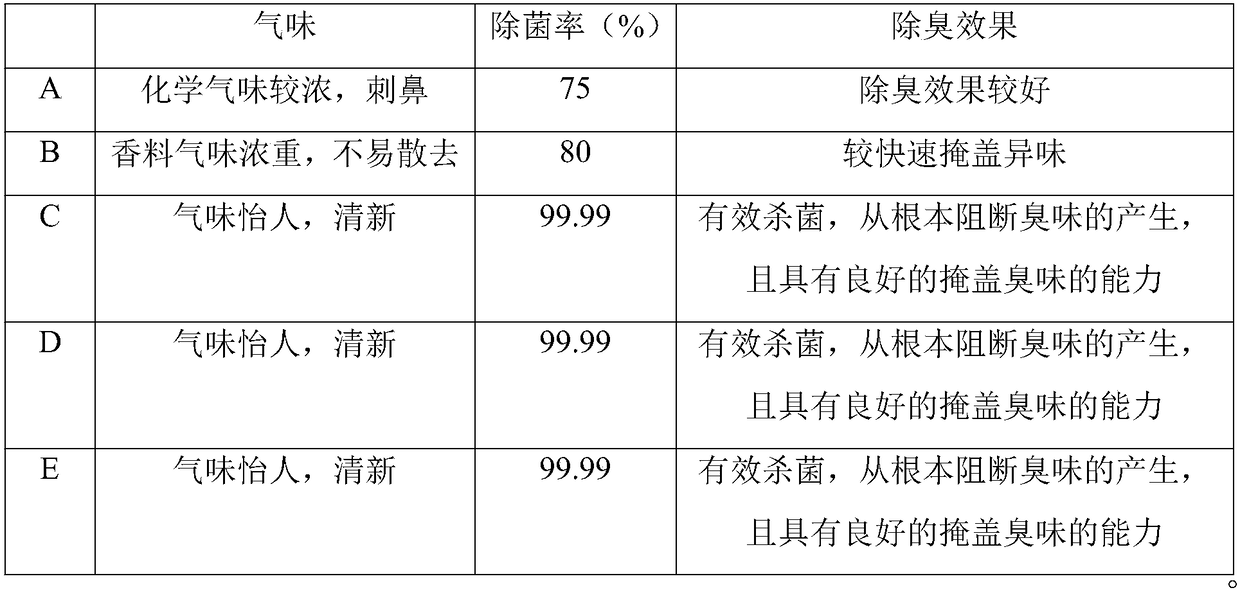

A technology of activated carbon and deodorant, which is applied in deodorization, grain treatment, disinfection, etc. It can solve the problems of reducing the collision probability of materials and water with knives, hindering the deodorization effect of microbial deodorants, and the difficulty of obtaining bacterial agents. Achieve good bactericidal effect, good odor masking, and no toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

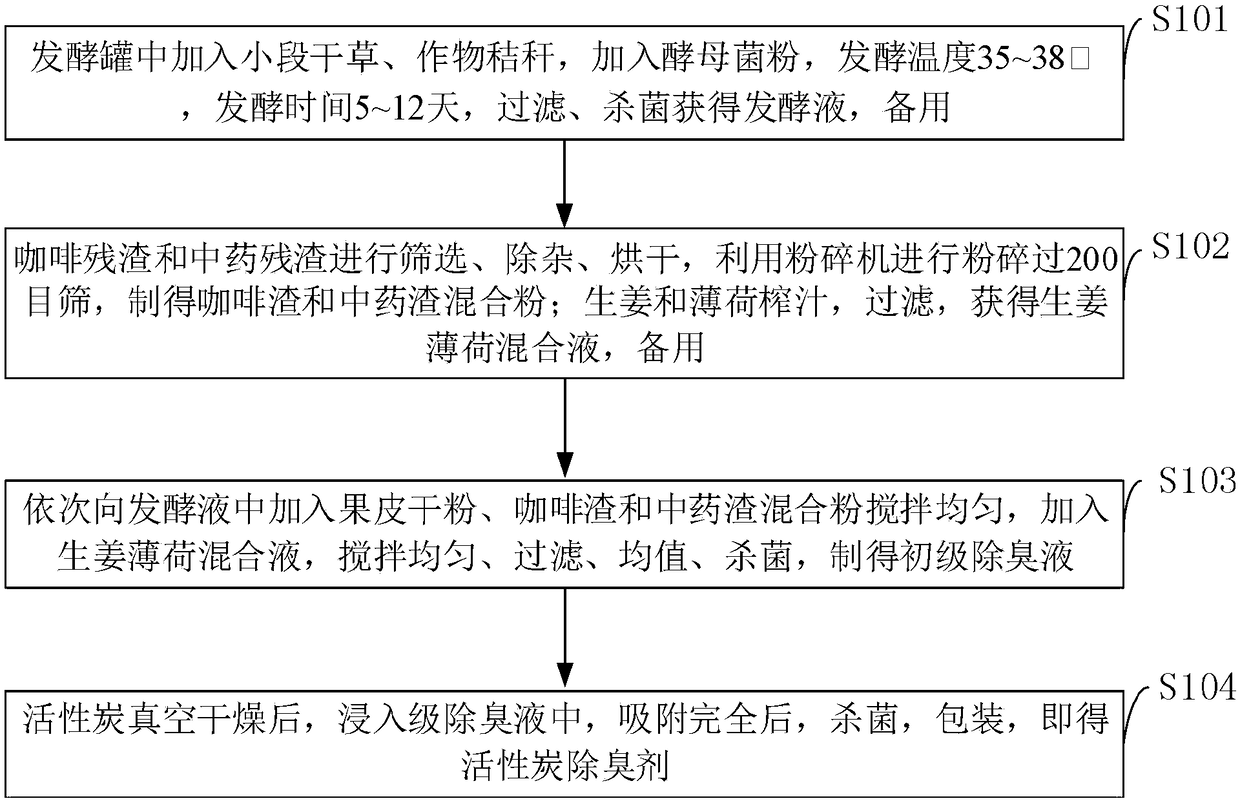

[0043] Such as figure 1 Shown, the preparation method of the activated carbon deodorant that the embodiment of the present invention provides specifically comprises the following steps:

[0044] S101: Add small pieces of hay and crop straw into the fermenter, add yeast powder, ferment at 35-38°C, ferment for 5-12 days, filter and sterilize to obtain fermented liquid, and set aside;

[0045] S102: Screen coffee residues and traditional Chinese medicine residues, remove impurities, and dry them, and use a pulverizer to crush them through a 200-mesh sieve to obtain a mixed powder of coffee grounds and traditional Chinese medicine residues; extract juice from ginger and mint, and filter to obtain a mixture of ginger and mint. spare;

[0046] S103: Add dry fruit peel powder, coffee grounds and traditional Chinese medicine residue mixed powder to the fermented liquid in turn, stir evenly, add ginger mint mixed liquid, stir evenly, filter, average, and sterilize to prepare a primary...

Embodiment 1

[0066] The activated carbon deodorant provided by the embodiment of the present invention consists of 100 parts of activated carbon, 30 parts of dry fruit peel powder, 10 parts of coffee grounds powder, 20 parts of traditional Chinese medicine residue powder, 10 parts of hay, 10 parts of crop straw, and 5 parts of yeast powder according to the parts by mass. , 7 parts of ginger and 15 parts of mint.

Embodiment 2

[0068] The activated carbon deodorant provided by the embodiment of the present invention consists of 120 parts by mass of activated carbon, 50 parts of dry fruit peel powder, 16 parts of coffee grounds powder, 30 parts of traditional Chinese medicine residue powder, 14 parts of hay, 14 parts of crop straw, and 9 parts of yeast powder , 9 parts of ginger and 19 parts of mint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com