A mechanical wood liquefaction device

A liquefaction device and mechanical technology, applied in the field of wood processing, can solve the problems of single setting mode, increase equipment use cost, reduce processing efficiency, etc., and achieve the effects of abundant raw material sources, reduced labor intensity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

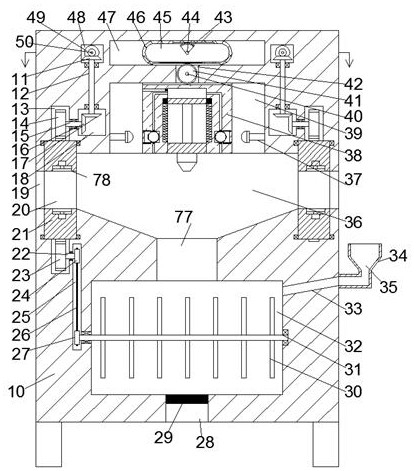

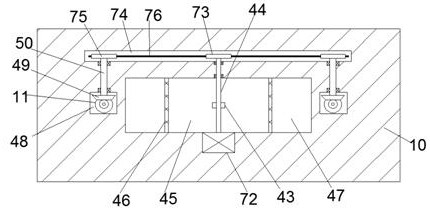

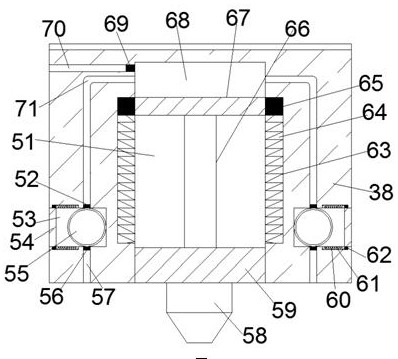

[0023] like Figure 1-3As shown, a mechanical wood liquefaction device of the present invention includes a liquefaction tank 10 fixedly arranged on a frame, and a first installation cavity is symmetrically arranged in the left and right sides of the liquefaction tank 10, and the first installation cavity is rotated to The bearing is rotatably installed with a rotating disk 21, and the rotating disk 21 is provided with a clamping cavity 20 penetrating left and right, and a cavity 36 is communicated between the left and right first installation cavities, and the cavity 36 is The top wall is provided with a first slide groove 39, a slide table 38 is slidably installed in the first slide groove 39, the top end surface of the slide table 38 is provided with a first rack, and the slide table 38 is provided with a downward opening. The second slide groove 51, the inner top wall of the second slide groove 51 is communicated with a sealing cavity 68, and the push plate 67 and the insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com