Regular polygonal constant-cross-section anti-bumping structure applied to composite material vehicle threshold

A regular polygon, composite material technology, applied in the superstructure, superstructure sub-assemblies, vehicle components, etc., can solve the problem of inapplicable composite material automobile thresholds, etc., to avoid the risk of galvanic corrosion, simple and convenient operation, and reduce intrusion amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

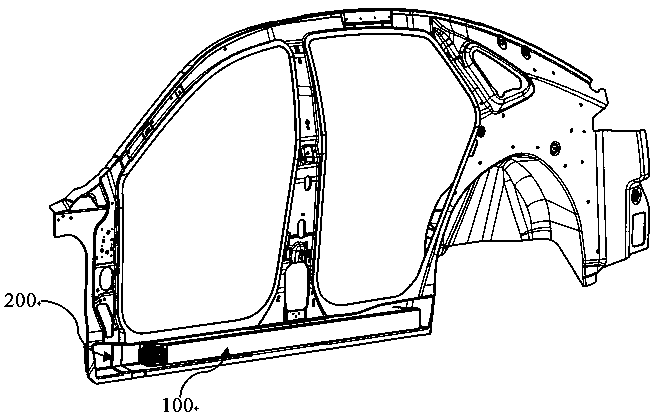

[0031] figure 1 It is a schematic diagram of the assembly of the regular polygonal constant cross-section anti-collision structure 100 and the composite material automobile door sill in the embodiment of the present invention. Such as figure 1 As shown, in this embodiment, the outer contour surface of the right side of the regular polygonal anti-collision structure 100 is attached to the inner cavity surface of the composite automobile door sill inner panel 200, and the two are bonded and fixed by a flexible structural glue; The outer contour surface of the left side of the cross-section anti-collision structure 100 is coated with tough structural glue, and it is glued and fixed with the inner cavity surface of the composite material automobile door sill outer panel; A bonding gap of 0 to 1 mm is provided between the surfaces of the inner cavity to serve as the coating space for the above-mentioned tough structural adhesive. The selected tough structural adhesive can not only e...

Embodiment 2

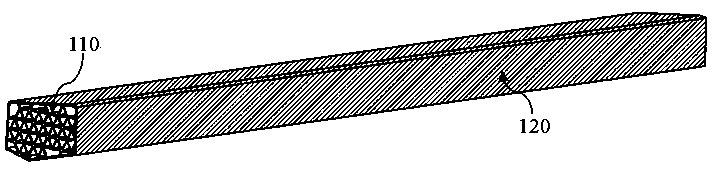

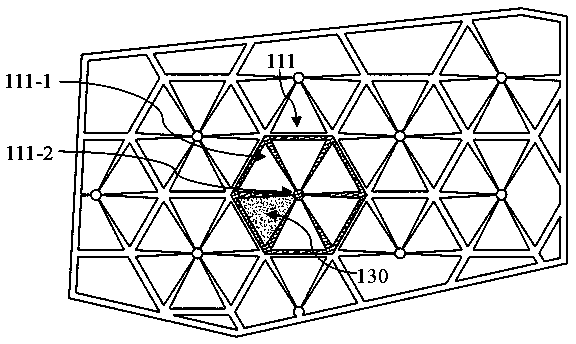

[0042] In this embodiment, in the regular polygonal uniform cross-section fiber-reinforced structure body 110 in the regular polygonal uniform cross-section anti-collision structure 100, an annular three-dimensional fiber weaving machine is used to prepare the multi-dimensional fiber-reinforced preform in the regular polygonal uniform cross-section fiber reinforced structure body 110. The fiber weaving direction of the multi-dimensional fiber-reinforced preform is customized according to the required stress conditions, and then the multi-dimensional fiber-reinforced preform is cured with epoxy resin to form a regular polygon under the traction device through the pultrusion process equipment The structural body 110 is reinforced with a uniform cross section fiber. Compared with the regular polygonal uniform cross-section fiber-reinforced structure body 110 formed by carbon fibers laid along the length of the regular polygonal uniform cross-section collision avoidance structure in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com