Non-equal-thick wall surface fork-shaped ring stress diffusion structure and design method thereof

A diffusion structure and fork-shaped ring technology, applied in the field of aerospace storage tanks, to achieve the effect of improved bearing capacity and uniform axial stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

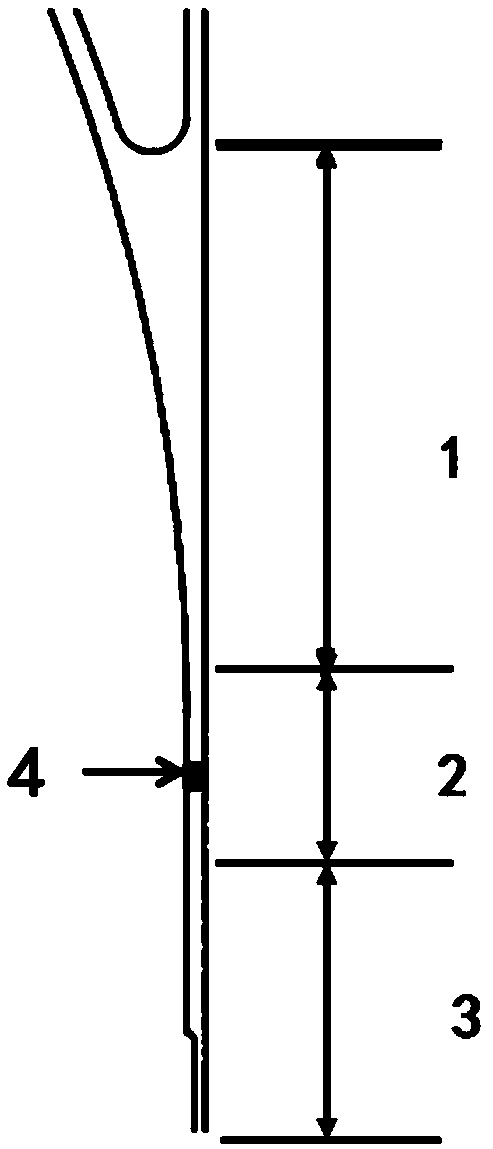

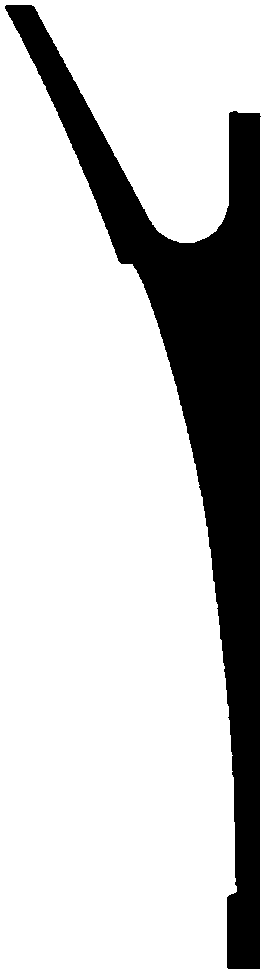

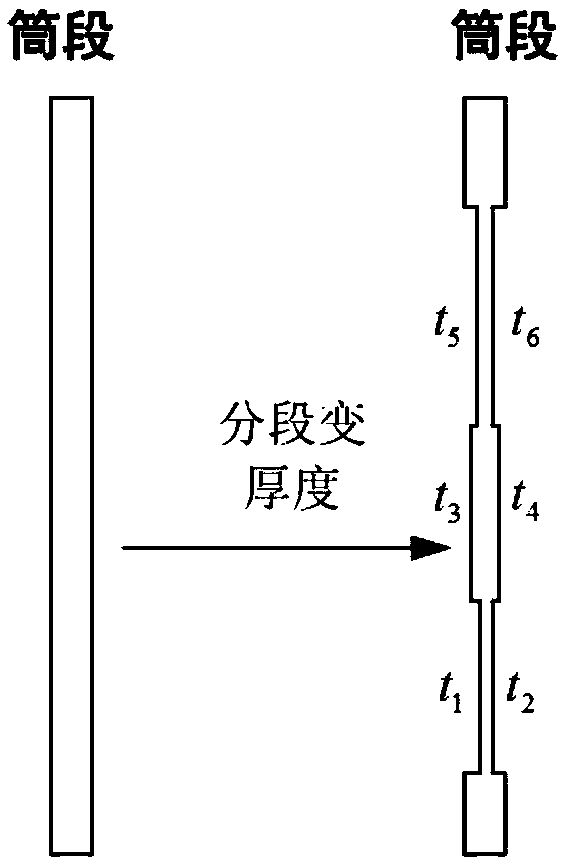

[0021] A fork-shaped ring stress diffusion structure with non-equal-thickness walls. The fork-shaped ring stress diffusion structure is an axisymmetric structure. The main characteristics of the structure are reflected in the cross-sectional configuration of the structure. The double-sided stress equalization method is used to determine the structure of the cross-sectional thickness parameter. The cross-sectional configuration of the stress diffusion structure of the fork-shaped ring mainly includes three areas: the fork-shaped ring transition zone 1 , the heat-affected zone of the weld seam 2 , and the barrel section area 3 , and the weld seam 4 is located in the heat-affected zone of the weld seam 2 . The outer surface of the fork-shaped ring transition zone 1 is vertical and smooth, and the inner surface is curved and smooth. The outer surface of the weld heat-affected zon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com