Preparation method of polythiophene anti-static silicon release film

A release film, anti-static technology, used in film/sheet adhesives, conductive coatings, film/sheet release liners, etc., can solve the problem of weak anti-static ability, achieve good anti-static ability, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

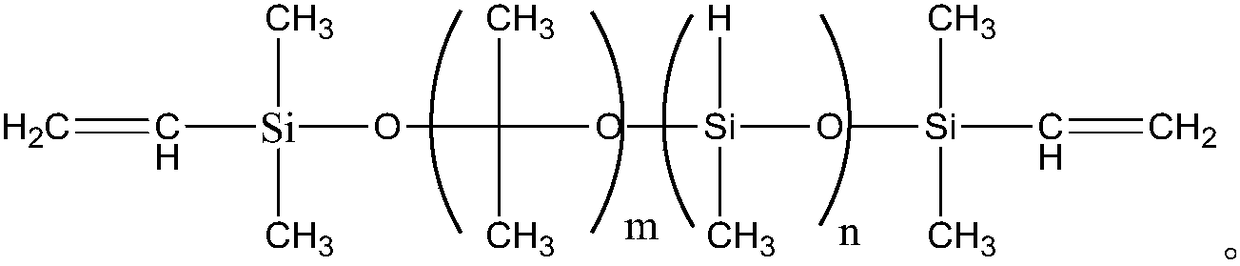

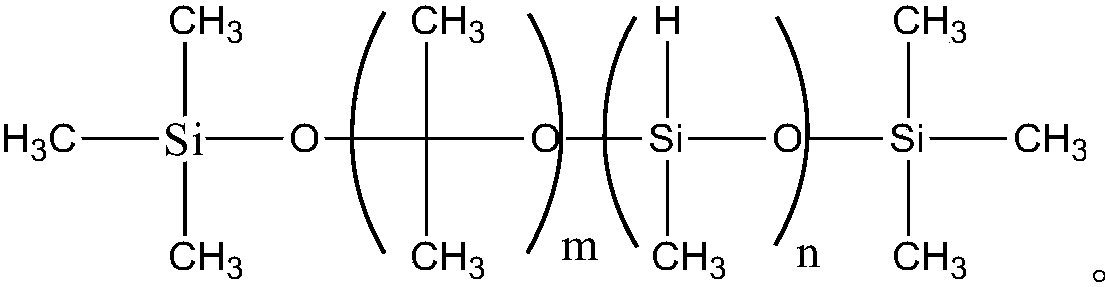

[0026] Embodiment 1: The polythiophene antistatic silicon-based release film includes a base film layer and an antistatic release layer, the base film layer is a transparent film of 75 microns, and the surface of the base film layer is filled with nano-scale Fumed silica, the outer surface of the base film layer is coated with an antistatic release layer; the coating liquid composition of the antistatic release layer is proportioned by weight: 40 parts of toluene, 40 parts Butanone, 5 parts of silicone oil B057, 5 parts of silicone oil B037, 1 part of silane coupling agent, 5 parts of auxiliary materials, 2 parts of polythiophene, 2 curing agents; the molecular weight of the silicone oil B057 is 40000-60000, and the viscosity is 18000 ~30000; its molecular structure is: The molecular weight of the silicone oil B037 is 40,000 to 60,000, and the viscosity is 18,000 to 30,000; its molecular structure is:

Embodiment 2

[0027] Embodiment 2: The polythiophene antistatic silicon-based release film includes a base film layer and an antistatic release layer, the base film layer is a transparent film of 75 microns, and the surface of the base film layer is filled with nano-scale Fumed white carbon black, the outer surface of the base film layer is coated with an antistatic release layer; the coating liquid composition of the antistatic release layer contains polythiophene; the coating of the antistatic release layer The composition of the cloth liquid is as follows: 30 parts of toluene, 50 parts of butanone, 10 parts of silicone oil B057, 2 parts of silicone oil B037, 1.5 parts of silane coupling agent, 2 parts of auxiliary materials, 3 parts of polythiophene, 3 parts of curing agent agent; the molecular weight of the silicone oil B057 is 40,000 to 60,000, and the viscosity is 18,000 to 30,000; its molecular structure is: The molecular weight of the silicone oil B037 is 40,000 to 60,000, and the ...

Embodiment 3

[0028] Embodiment 3: The polythiophene antistatic silicon-based release film includes a base film layer and an antistatic release layer, the base film layer is a transparent film of 75 microns, and the surface of the base film layer is filled with nano-scale Fumed white carbon black, the outer surface of the base film layer is coated with an antistatic release layer; the coating liquid composition of the antistatic release layer contains polythiophene; the coating of the antistatic release layer The composition of the cloth liquid is as follows: 50 parts of toluene, 30 parts of methyl ethyl ketone, 2 parts of silicone oil B057, 10 parts of silicone oil B037, 0.5 parts of silane coupling agent, 8 parts of auxiliary materials, 5 parts of polythiophene, 5 parts of curing agent agent; the molecular weight of the silicone oil B057 is 40,000 to 60,000, and the viscosity is 18,000 to 30,000; its molecular structure is: The molecular weight of the silicone oil B037 is 40,000 to 60,00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com