A kind of grinding stone floor and its construction method and application

A construction method and grinding technology, applied in the field of flooring, can solve the problems of non-pollution resistance, poor high temperature resistance, and weather resistance, and achieve the effects of increasing impact resistance and bearing capacity, improving semiconductor performance, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

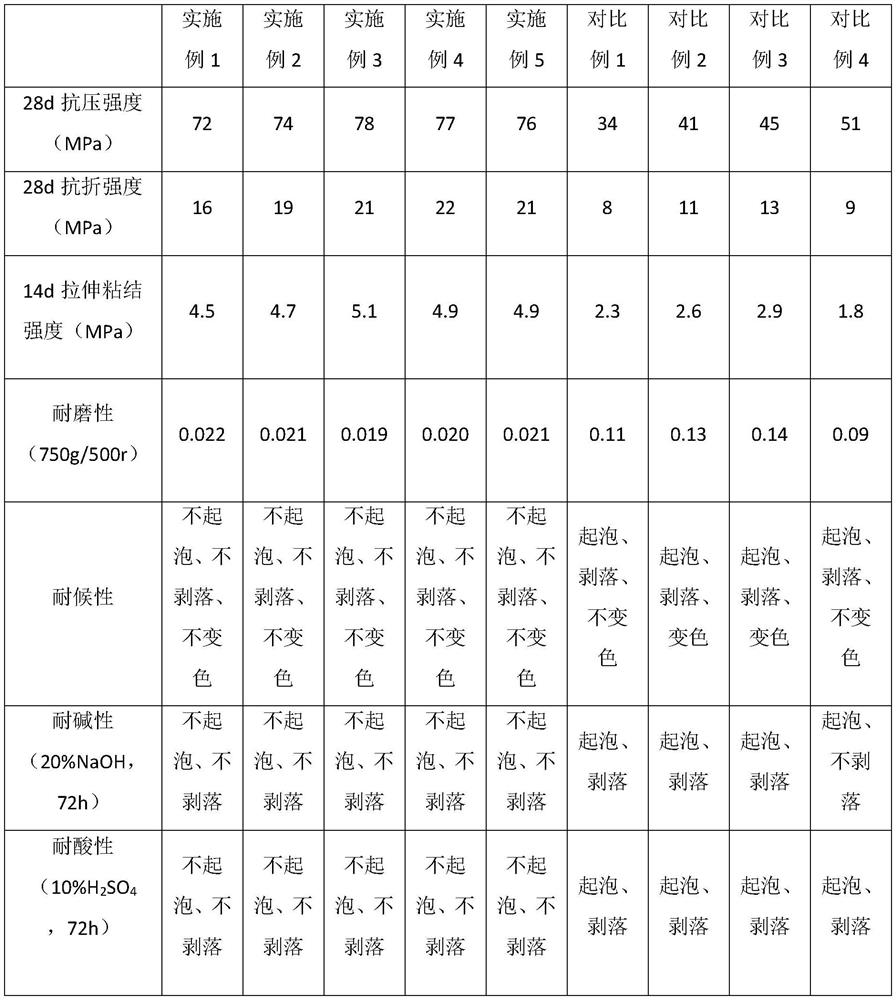

Embodiment 1

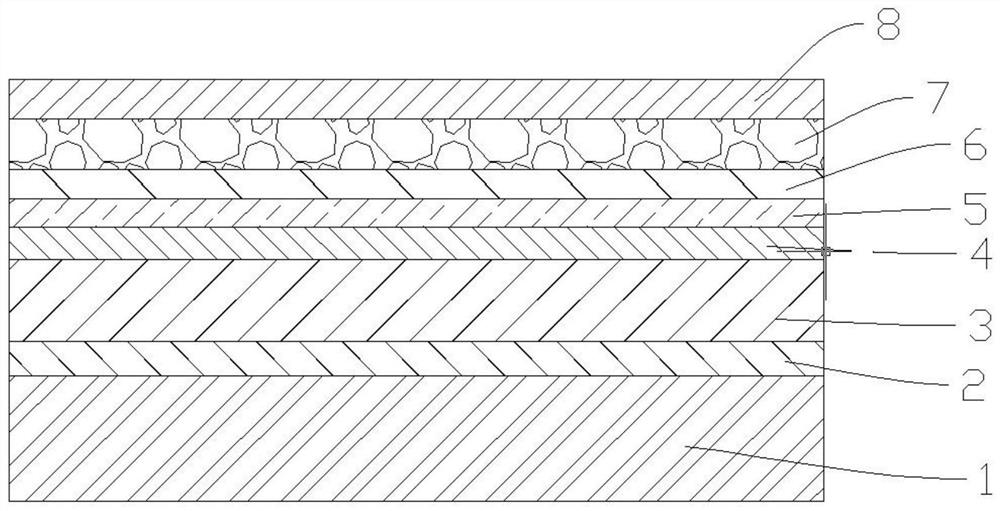

[0032] like figure 1 As shown, a grinding stone floor includes an isolation layer 2, a leveling layer 3, a primer layer 4, an anti-cracking layer 5, an anti-cracking layer 6, a grinding stone layer 7 and a surface layer 1, which are sequentially arranged on the base layer 1. Layer 8; the base layer 1 is a foundation or a building base layer, the isolation layer 2 is a PE film layer, the anti-crack inhibition layer 5 is a polypropylene fiber layer, the anti-crack layer 6 is a glass fiber layer, and the surface Layer 8 is an anti-soiling polishing layer.

[0033] The grinding stone layer 7 is prepared by using the following raw materials in parts by weight: 6 parts of copper ore tailings, 10 parts of stones, 10 parts of stone materials, 8 parts of broken shell pieces, 1 part of zirconium powder, 15 parts of epoxy resin, lemon 0.5 part of acid, 306 parts of curing agent DMP-, 3 parts of butyl glycidyl ether, 2 parts of polyacrylic resin.

[0034] Described leveling layer 3 is p...

Embodiment 2

[0046] like figure 1 As shown, a grinding stone floor includes an isolation layer 2, a leveling layer 3, a primer layer 4, an anti-cracking layer 5, an anti-cracking layer 6, a grinding stone layer 7 and a surface layer 1, which are sequentially arranged on the base layer 1. Layer 8; the base layer 1 is a foundation or a building base layer, the isolation layer 2 is a PE film layer, the anti-crack inhibition layer 5 is a polypropylene fiber layer, the anti-crack layer 6 is a glass fiber layer, and the surface Layer 8 is an anti-soiling polishing layer.

[0047] The grinding stone layer 7 is prepared by using the following raw materials in parts by weight: 7 parts of tungsten ore tailings, 11 parts of stones, 11 parts of stone materials, 9 parts of broken shell pieces, 2 parts of zirconium powder, 20 parts of epoxy resin, lemon 1 part of acid, 8 parts of curing agent DMP-30, 4 parts of butyl glycidyl ether, 3 parts of polyacrylic resin.

[0048] Described leveling layer 3 is ...

Embodiment 3

[0060] like figure 1 As shown, a grinding stone floor includes an isolation layer 2, a leveling layer 3, a primer layer 4, an anti-cracking layer 5, an anti-cracking layer 6, a grinding stone layer 7 and a surface layer 1, which are sequentially arranged on the base layer 1. Layer 8; the base layer 1 is a foundation or a building base layer, the isolation layer 2 is a PE film layer, the anti-crack inhibition layer 5 is a polypropylene fiber layer, the anti-crack layer 6 is a glass fiber layer, and the surface Layer 8 is an anti-soiling polishing layer.

[0061] The grinding stone layer 7 is prepared by using the following raw materials by weight: 8 parts of copper ore tailings, 12 parts of stones, 12 parts of stone materials, 10 parts of broken shell pieces, 3 parts of zirconium powder, 22 parts of epoxy resin, lemon 2 parts of acid, 309 parts of curing agent DMP-309, 5 parts of butyl glycidyl ether, 4 parts of polyacrylic resin.

[0062] Described leveling layer 3 adopts th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com