Aircraft organic glass surface protecting film and preparation method thereof

A surface protection film and plexiglass technology, which is applied in the field of aircraft plexiglass surface protection film and its preparation, can solve the problems of chemical pollution, high protection difficulty, and inability to achieve stable protection, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method for aircraft plexiglass surface protective film, is characterized in that, the method comprises the following steps:

[0029] Step 1. Weigh each component raw material as required;

[0030] Step 2, adding ethylene-vinyl alcohol copolymer, butyl acrylate resin, and polyurethane into a high-speed mixer, the stirring speed is 300-600r / min, and the stirring time is 60-90min to obtain a mixture A;

[0031] Step 3, uniformly mixing graphene, composite emulsion and organosiloxane to obtain mixture B;

[0032] Step 4, add mixture A, mixture B, 1,4-tetramethylene diisocyanate, dichlorotetrafluoroethane, trimethylolpropane and 1,3-propanediol into a high-speed mixer, stir well to make Mix all the materials evenly, the stirring speed is 300-600r / min, and the stirring time is 70-120min, then add the mixture into the reaction kettle, heat up to 100-130°C, and keep it warm for 15-20min to obtain the mixture C;

[0033] In step five, the mixture C prepared in st...

Embodiment 2

[0076] A preparation method for aircraft plexiglass surface protective film, is characterized in that, the method comprises the following steps:

[0077] Step 1. Weigh each component raw material as required;

[0078] Step 2, adding ethylene-vinyl alcohol copolymer, butyl acrylate resin, and polyurethane into a high-speed mixer, the stirring speed is 500r / min, and the stirring time is 70min to obtain a mixture A;

[0079] Step 3, uniformly mixing graphene, composite emulsion and organosiloxane to obtain mixture B;

[0080] Step 4, add mixture A, mixture B, 1,4-tetramethylene diisocyanate, dichlorotetrafluoroethane, trimethylolpropane and 1,3-propanediol into a high-speed mixer, stir well to make All the materials were mixed evenly, the stirring speed was 500r / min, and the stirring time was 100min, then the mixture was added into the reaction kettle, the temperature was raised to 120°C, and the mixture was kept at 18min to obtain the mixture C.

[0081] Step 5, the mixture C ...

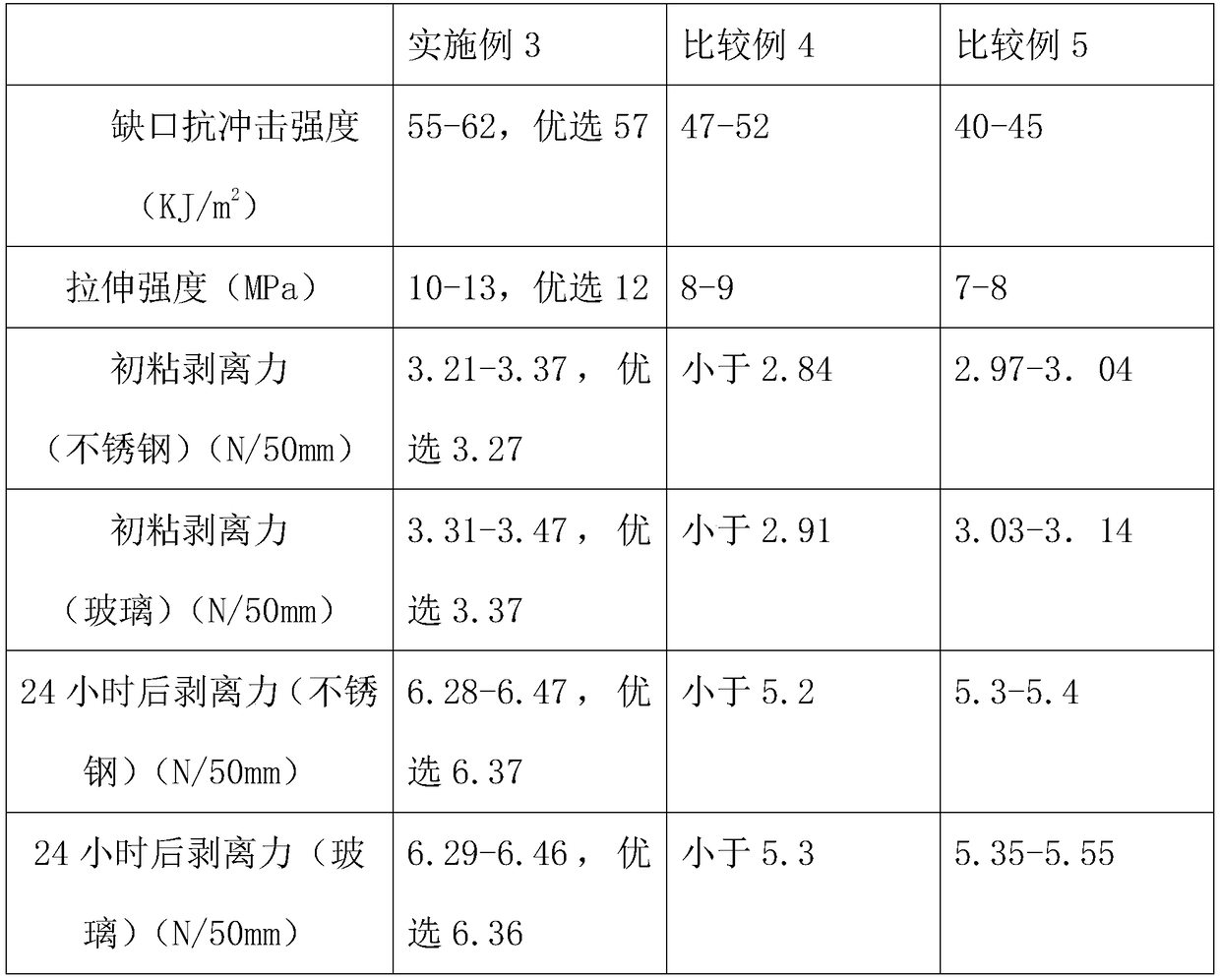

Embodiment 3

[0110] A kind of aircraft plexiglass surface protective film is characterized in that this protective film is prepared by the method as described in embodiment 1 or embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com