Solid color repair primer for LED-UV woodware and preparation method thereof

A primer, solid color technology, applied in the direction of primer, coating, etc., can solve the problems of scratched surface of wood decoration, long drying time, formation of small depressions, etc., to achieve superior performance, good curing performance, heat radiation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The UV wood transparent repair primer dedicated to LED-UV of the present embodiment is calculated by weight percentage, and the primer includes the following components: 31 parts of aminoacrylate resin, 40 parts of special functional resin, 10 parts of monomer, light 5 parts of initiator, 0.30 parts of anti-settling agent, 0.20 parts of wetting and dispersing agent, 13.5 parts of UV red paste.

[0050] The preparation method of the UV wood transparent repair primer special for LED-UV of the present embodiment is as follows:

[0051] Step 1, under the condition of avoiding sunlight or ultraviolet light, slowly mix aminoacrylate resin, low-energy curing functional acrylic resin, monomer, photoinitiator, anti-settling agent, wetting and dispersing agent in sequence according to the above ratio Stir until evenly mixed, keep the temperature of the mixed material below 50°C during the stirring process, and the stirring speed is 1000-1200 rpm for 15 minutes;

[0052] Step 2: ...

Embodiment 2

[0054] The UV wood transparent repair primer dedicated to LED-UV of the present embodiment is calculated by weight percentage, and the primer includes the following components: 35 parts of aminoacrylate resin, 35 parts of acrylate resin, 8 parts of monomer, photoinitiated 6 parts of anti-settling agent, 0.3 part of anti-settling agent, 0.2 part of wetting and dispersing agent, UV black paste.

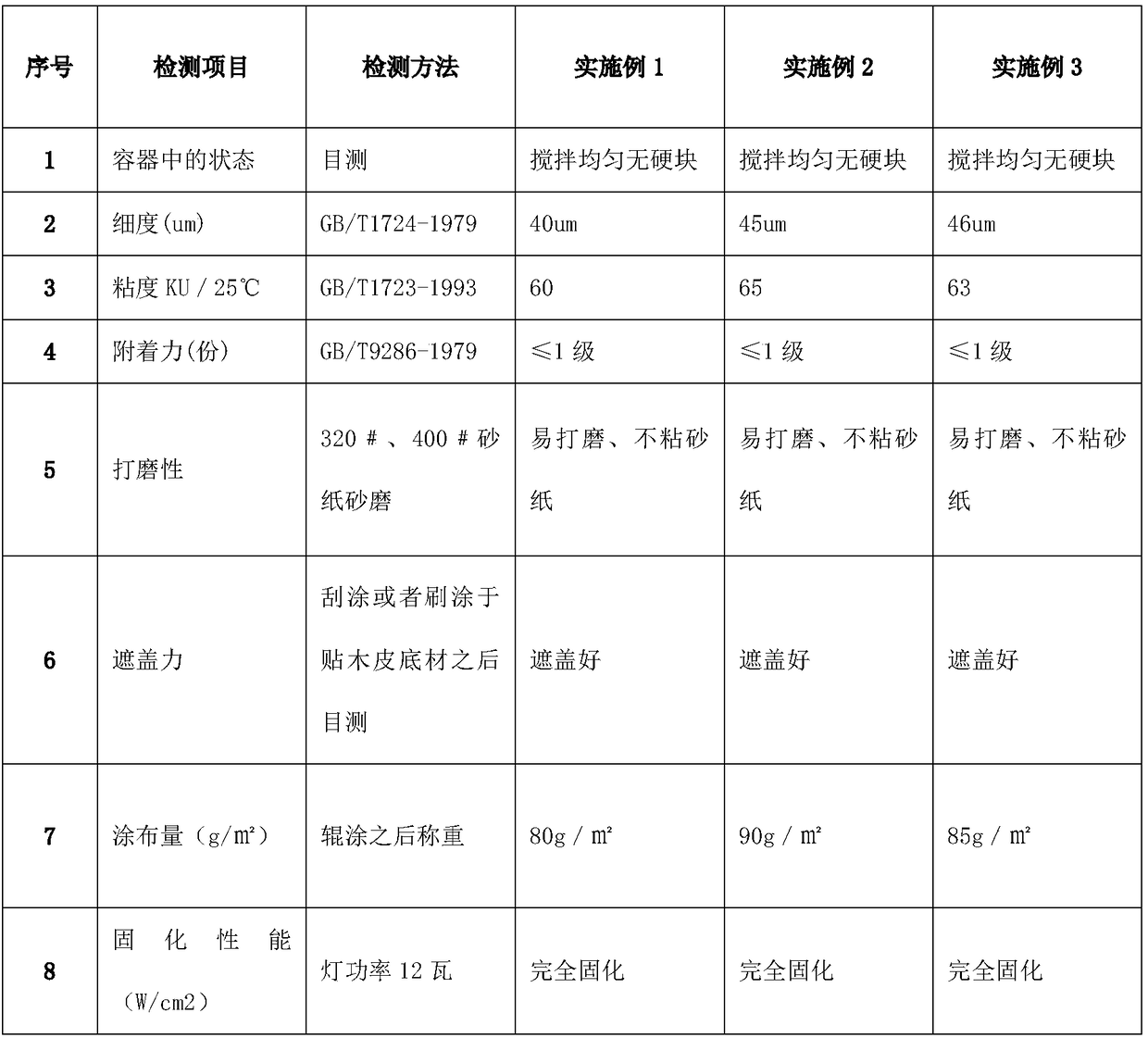

[0055]According to the above-mentioned proportion of this example, repeat the preparation method described in Example 1, and then the solid-color repair primer for LED-UV woodware of the present invention can be obtained. Performance inspection standards and test results are shown in the corresponding data of Example 2 in Table 1.

Embodiment 3

[0057] The UV wood transparent repair primer dedicated to LED-UV of the present embodiment is calculated by weight percentage, and the primer includes the following components: 39 parts of aminoacrylate resin, 31 parts of acrylate resin, 6 parts of monomer, photoinitiated 7 parts of anti-settling agent, 0.3 parts of anti-settling agent, 0.2 parts of wetting and dispersing agent, UV white paste.

[0058] According to the above-mentioned proportion of this example, repeat the preparation method described in Example 1, and then the solid-color repair primer for LED-UV woodware of the present invention can be obtained. Performance inspection standards and test results are shown in the corresponding data of Example 3 in Table 1.

[0059] The solid-color repair primers for LED-UV woodware of the above-mentioned embodiments have the advantages of superior product performance, high efficiency, good low-energy curing performance, good filling performance, good hiding power, easy sandin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com