Variable pressure difference load sensitive multiple-way valve

A load-sensitive, multi-way valve technology, applied in the hydraulic field, can solve the problems of unfavorable intelligent development of load-sensitive multi-way valves, low shunt accuracy, valve port flow gain, etc. The effect of fixing and reducing the flow gain of the valve port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

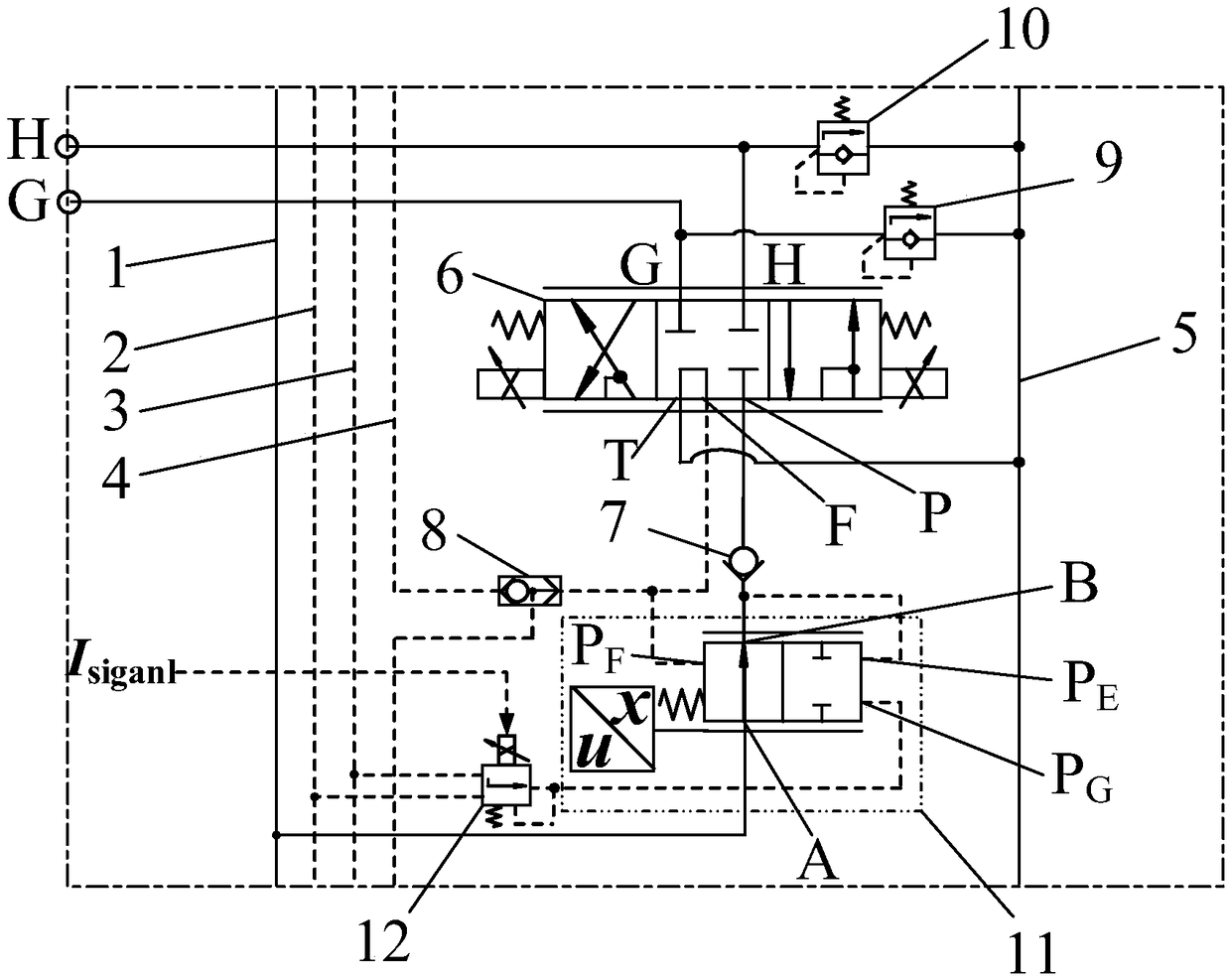

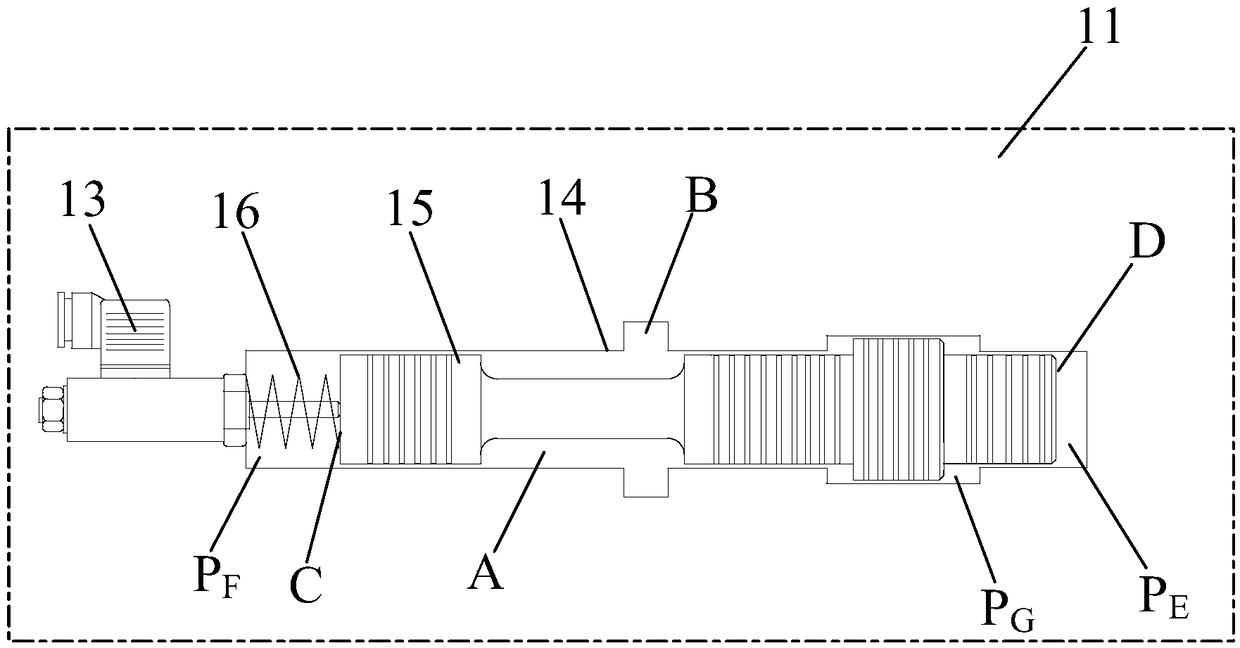

[0034] A variable pressure differential load sensitive multi-way valve, including at least one valve group, wherein each valve group includes an oil inlet circuit 1, a pilot control oil inlet circuit 2, a pilot control return oil circuit 3, a load sensing oil circuit 4, a return circuit Oil circuit 5, reversing valve 6, one-way valve 7, shuttle valve 8, first one-way relief valve 9, second one-way relief valve 10, also includes electro-hydraulic pressure compensation valve 11 and first pilot decompression valve 12;

[0035] Such as figure 2 As shown, the electro-hydraulic pressure compensation valve 11 is arranged before the reversing valve 6, the oil inlet A of the electro-hydraulic pressure compensation valve 11 communicates with the oil inlet 1, and the oil outlet B of the electro-hydraulic pressure compensation valve 11 communicates with the check valve The oil inlet of 7, the second control chamber P of the electro-hydraulic pressure compensation valve 11 E Connected, ...

Embodiment 2

[0048] Such as Figure 6 As shown, the second embodiment of a variable pressure differential load sensitive multi-way valve of the present invention is the same as the embodiment 1 in terms of structure and composition, the difference is that the connection mode between the electro-hydraulic pressure compensation valve 11 and the system is changed, and The reversing valve 6 is an electro-hydraulic proportional reversing valve.

[0049] The electro-hydraulic pressure compensation valve 11 is arranged after the reversing valve 6. The oil outlet of the check valve 7 is connected with the oil inlet A of the electro-hydraulic pressure compensation valve 11 and the second control chamber P of the electro-hydraulic pressure compensation valve 11. E Connected, the first control chamber P of the electro-hydraulic pressure compensation valve 11 F Connected with the load sensing oil circuit 4, the third control chamber P of the electro-hydraulic pressure compensation valve 11 G It comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com