Friction drive system capable of diagnosing intelligently and maintaining controlling agilely

A friction-driven, intelligent diagnosis technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of complex system structure, high integration, catastrophic accidents, etc., to achieve simple system maintenance and ensure reliability. , fast and convenient effect of equipment replacement and system expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

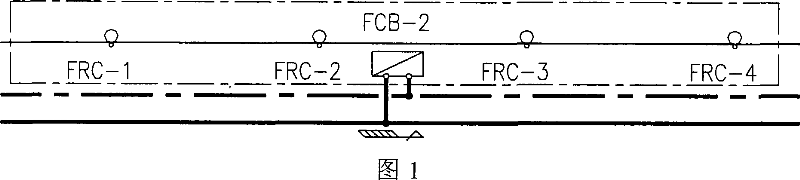

[0029] Figure 1 is the layout diagram of the friction drive device and control box. The friction drive devices FRC1~4 are the main body of the entire conveyor line. Divided into multiple groups, for example, each group can have four friction drives, and each group of friction drives is equipped with a control box FCB-2 to control the start and stop of this group of friction drives FRC1-4.

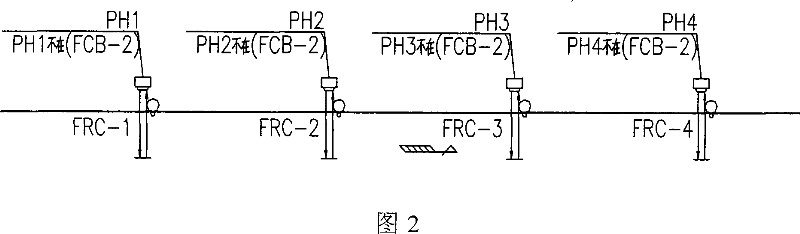

[0030] As shown in Figure 2 is the layout of the friction drive device and photoelectric switch. There is a photoelectric switch PH1~4 next to each friction drive device FRC1~4, which is used to detect whether there is a workpiece here, and input the detection signal to this group. In the substation of the control box FCB-2 of the friction drives FRC1-4. Take the operation of the control box FEC-2 as an example, when the photoelectric switch PH2 is in the ON position, it detects that there is a trolley or spreader at the friction drive device FRC-2; when the photoelectric switch PH3 is in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com