Precise temperature control type heat pump hot blast heater control system and control method

A control system and control method technology, applied in the field of grain drying, can solve the problems affecting the temperature stability of the air outlet, the drop of the air outlet temperature of the unit, and the low temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0170] Hereinafter, a control system and a control method for an accurate temperature-controlled heat pump hot blast stove of the present invention will be further described in detail according to the accompanying drawings and specific embodiments of the present invention.

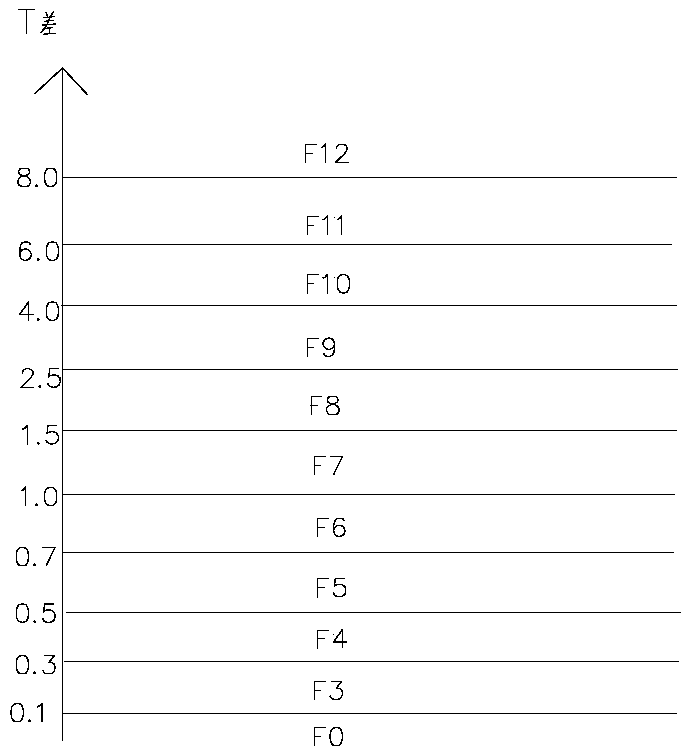

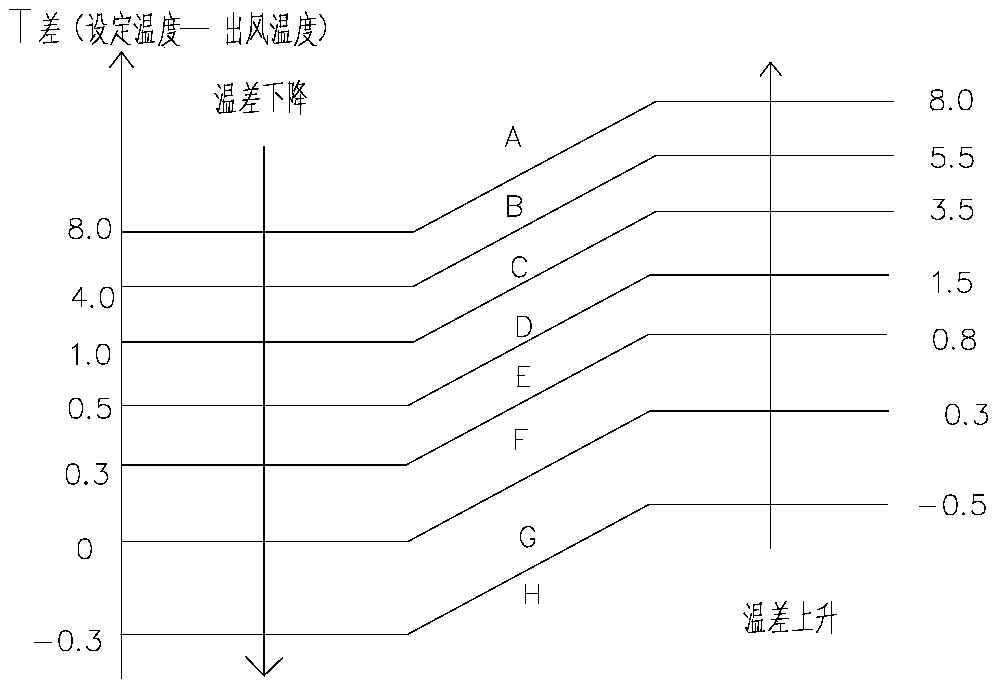

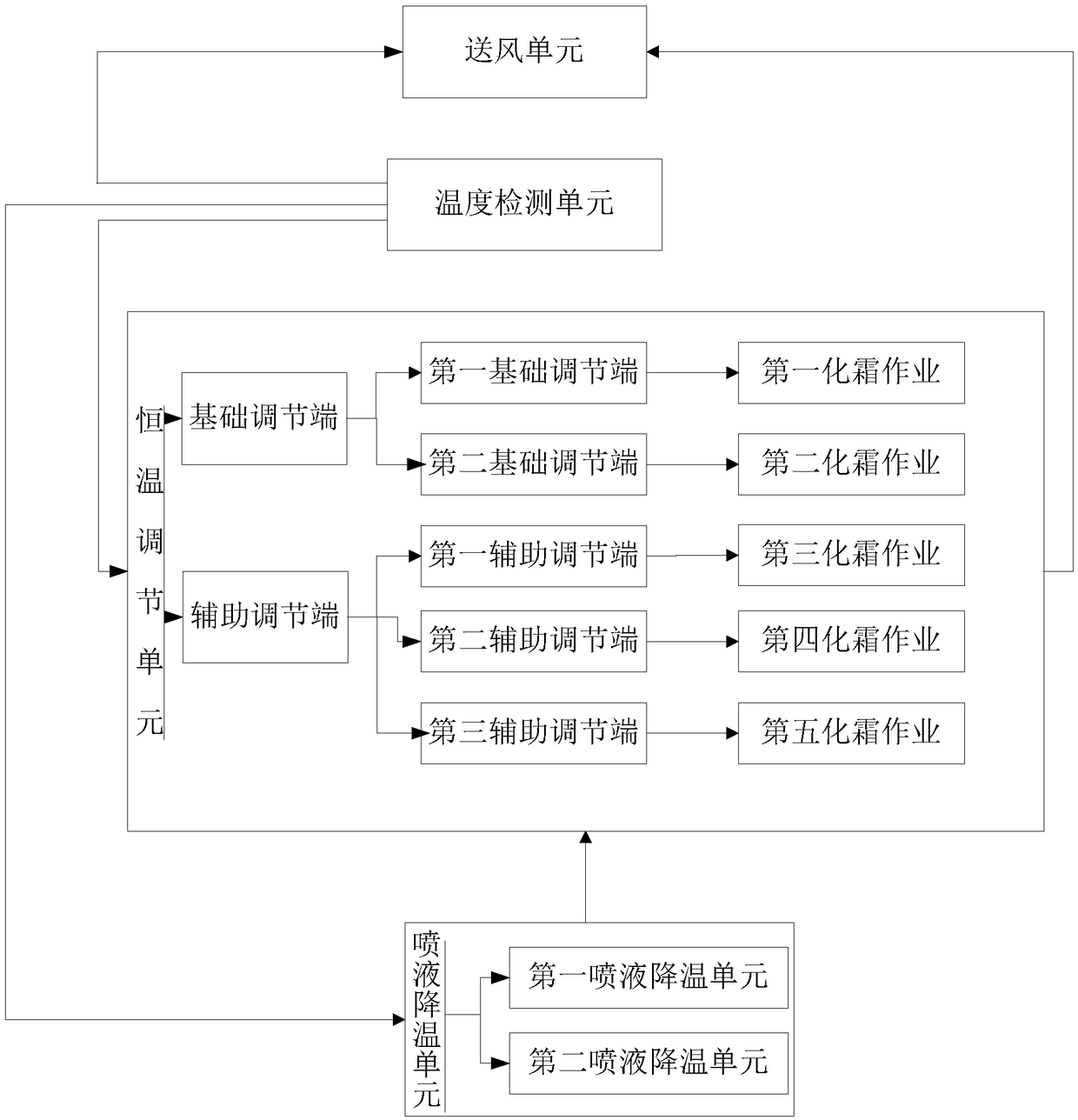

[0171] like figure 1 A precise temperature control type heat pump hot blast stove control system shown in

[0172] A temperature detection unit, a constant temperature adjustment unit and an air supply unit are arranged in the control system;

[0173] A basic adjustment end and an auxiliary adjustment end are formed in the constant temperature adjustment unit;

[0174] The control system supplies hot air matching the set temperature into the air supply unit through the cooperation of the temperature detection unit and the thermostatic adjustment unit;

[0175] A first basic regulating end and a second basic regulating end are formed on the basic regulating end of the thermostatic regulating unit;

[017...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com