Novel external pressurized and internal liquefied pure nitrogen preparation device

A new type of pure nitrogen technology, which is applied in the field of new external pressurized and internal liquefaction pure nitrogen production devices, can solve the problems of difficult selection of liquid nitrogen pumps, low device extraction rate and high device extraction rate, and achieves low cold loss and pressure utilization. The effect of high efficiency and low energy consumption of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the embodiments and the accompanying drawings. The following examples are only used to illustrate the present invention, but are not intended to limit the scope of the present invention.

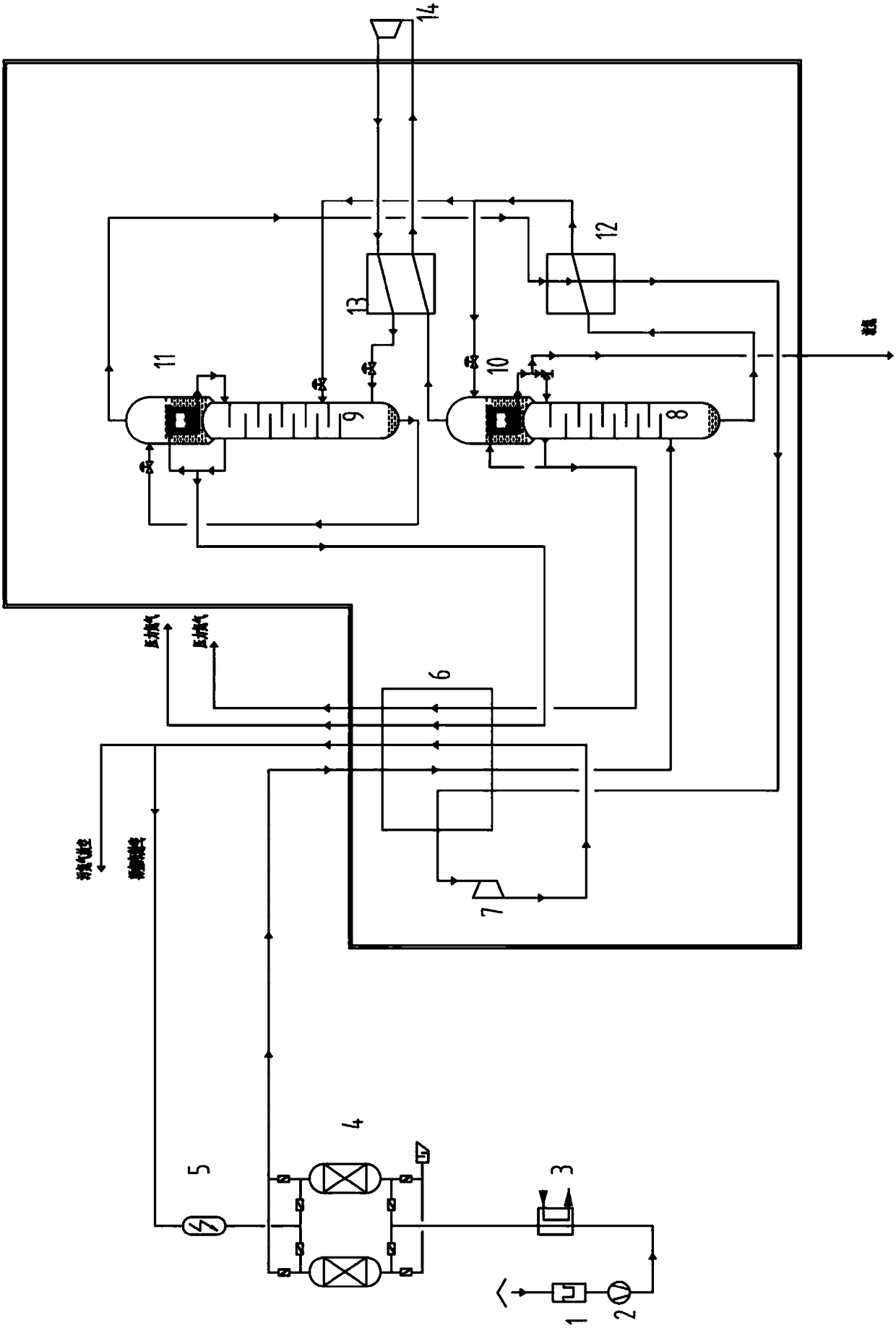

[0024] A new type of external pressurized internal liquefied pure nitrogen production device, including a filter 1, a turbo air compressor 2, an air pre-cooling unit 3, an alternately used molecular sieve adsorber 4, an electric heater 5, and a main heat exchanger 6 , booster expander 7, rectification tower I8, rectification tower II9, condensation evaporator I10, condensation evaporator II11, subcooler 12, liquefier 13, supercharger 14,

[0025] Filter 1, turbine air compressor 2, air pre-cooling unit 3, alternately used molecular sieve adsorber 4, electric heater 5, supercharger 14 are located outside the cold box, main heat exchanger 6, booster expander 7. Distillation tower I8, rectification tower II9, cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com