Multi-measurement-point temperature sensor

A temperature sensor and multi-measuring point technology, applied in thermometers, instruments, and thermometers with electric/magnetic elements that are directly sensitive to heat, can solve problems such as long temperature response time, hardening of EO catalysts, and reduced insulation of thermocouples , to achieve the effect of overcoming the leakage of insulating materials, simple structure and wiring, and reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

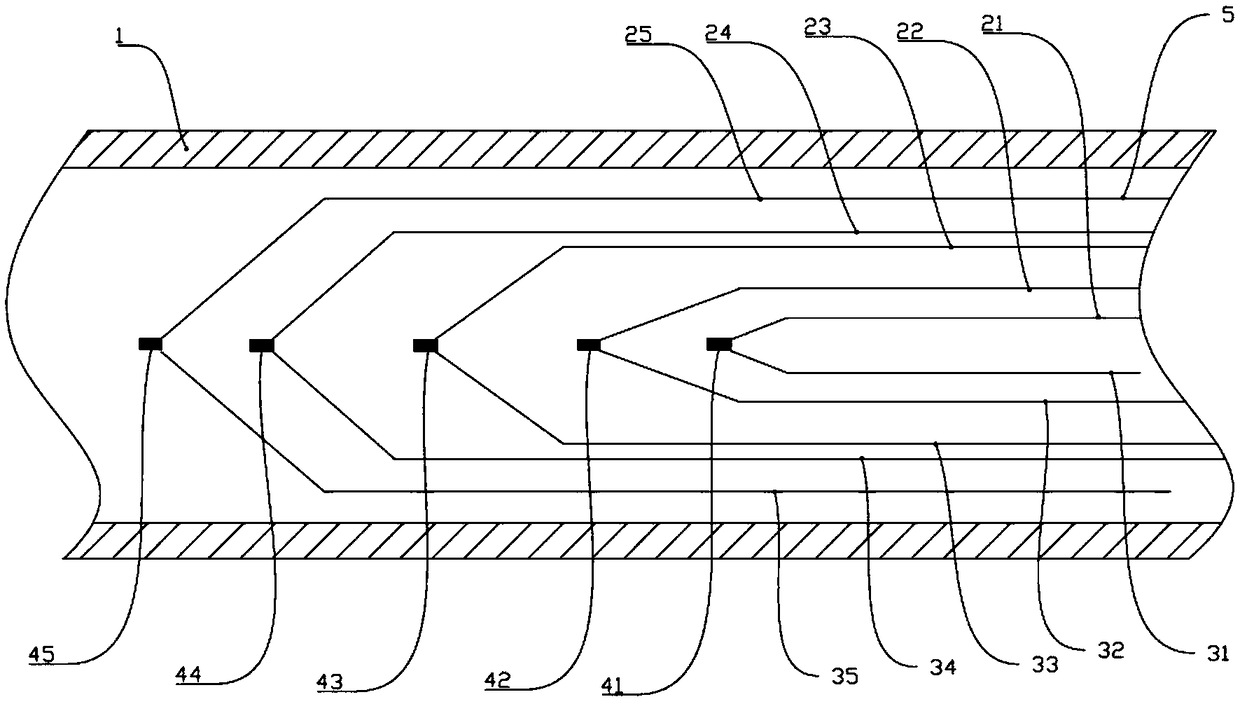

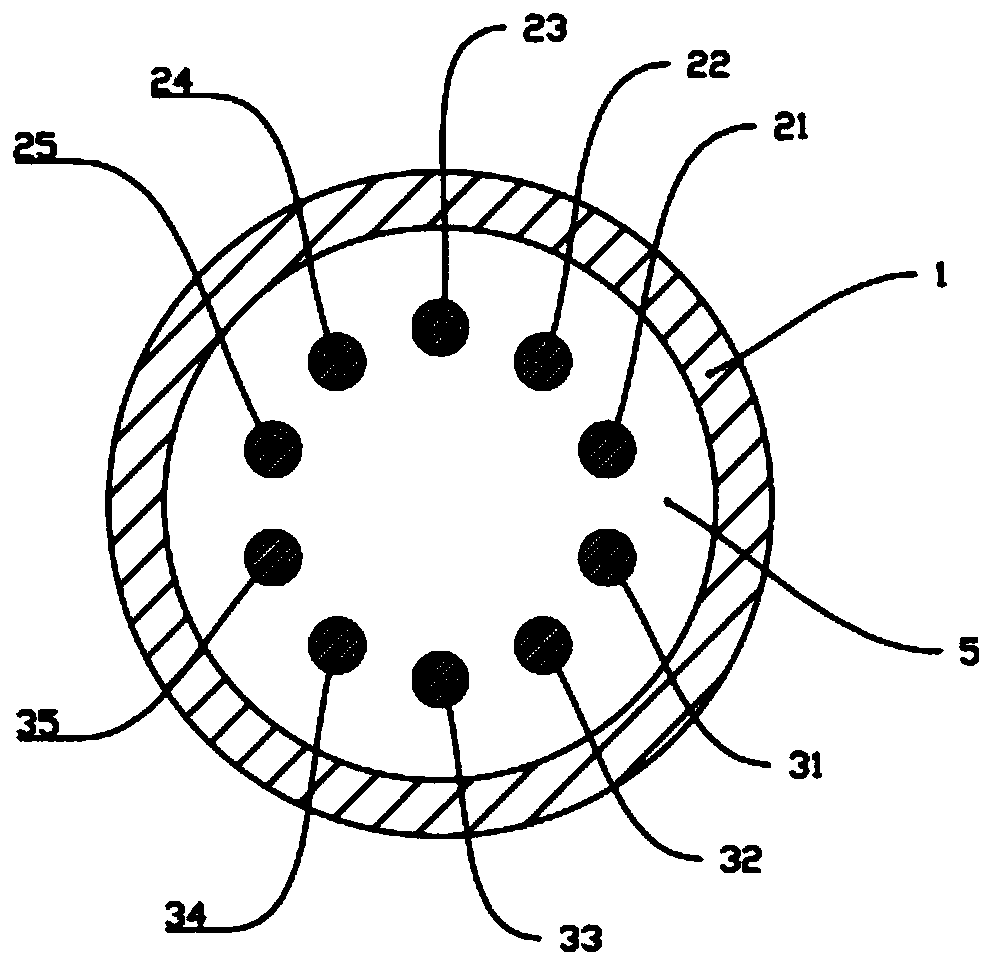

[0022] see Figure 1~2 , the embodiment of the present invention includes:

[0023] A multi-measuring point temperature sensor, comprising a metal armor layer 1, and ten even wires are evenly arranged on the inside of the metal armor layer 1, which are respectively five positive pole dual wires 21-25 and five negative pole dual wires 31 ~35, the ten even wires form five temperature measuring points 41~45 sequentially in the axial direction in the metal armor layer 1, and at each temperature measuring point there is one positive pole and one negative pole Wire welding, the five temperature measuring points 41-45 are evenly distributed along the axial direction of the metal armor layer 1, and the aluminum oxide insulating layer is passed between the ten even wires and between the even wires and the metal armor layer 1 5 isolation, the purity of the alumina insulation layer is 99.99%, the metal armor layer 1 is made of high hardness and good ductility stainless steel, and the th...

Embodiment 2

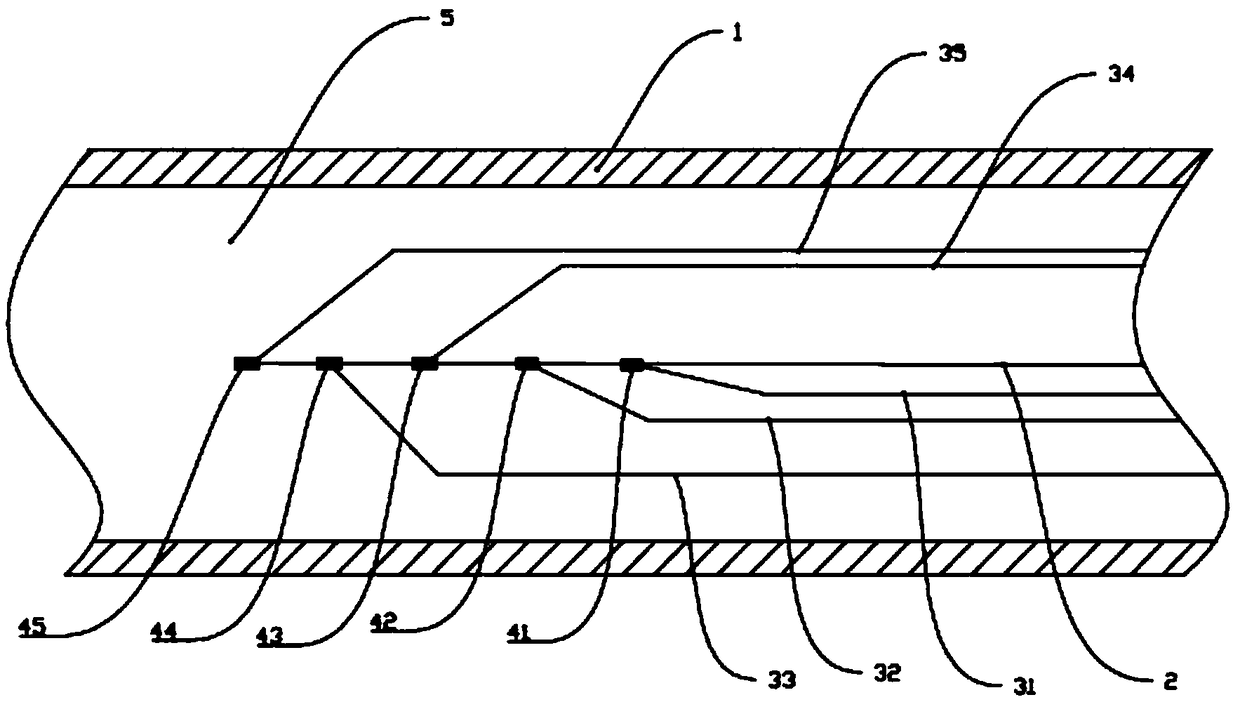

[0025] see Figure 3-4 , the embodiment of the present invention includes:

[0026] A multi-measuring-point temperature sensor, comprising a metal armor layer 1, five negative pole wires 31-35 are evenly arranged in the interior of the metal armor layer 1, and one positive pole wire is arranged at the center of the circle 2. Five temperature measuring points 41 to 45 are evenly arranged in the metal armor layer 1 along the axial direction, and each temperature measuring point has a negative pole wire connected to the positive pole wire 2 by welding, and the six pole wires Between the wires, even wires and the metal armor layer 1 are separated by an aluminum oxide insulating layer 5, the purity of the aluminum oxide insulating layer is 99.99%, and the metal armor layer 1 is made of stainless steel with high hardness and good ductility Made, the thickness of the metal armor layer 1 is 0.8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com