Au/CeO2/g-C3N4 composite material, electrochemical sensor and preparation method and application thereof

A composite material, g-c3n4 technology, applied in the field of Au/CeO2/g-C3N4 composite material, electrochemical sensor and its preparation, can solve ecological problems and other problems, achieve low cost, high-efficiency electrochemical detection, good selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

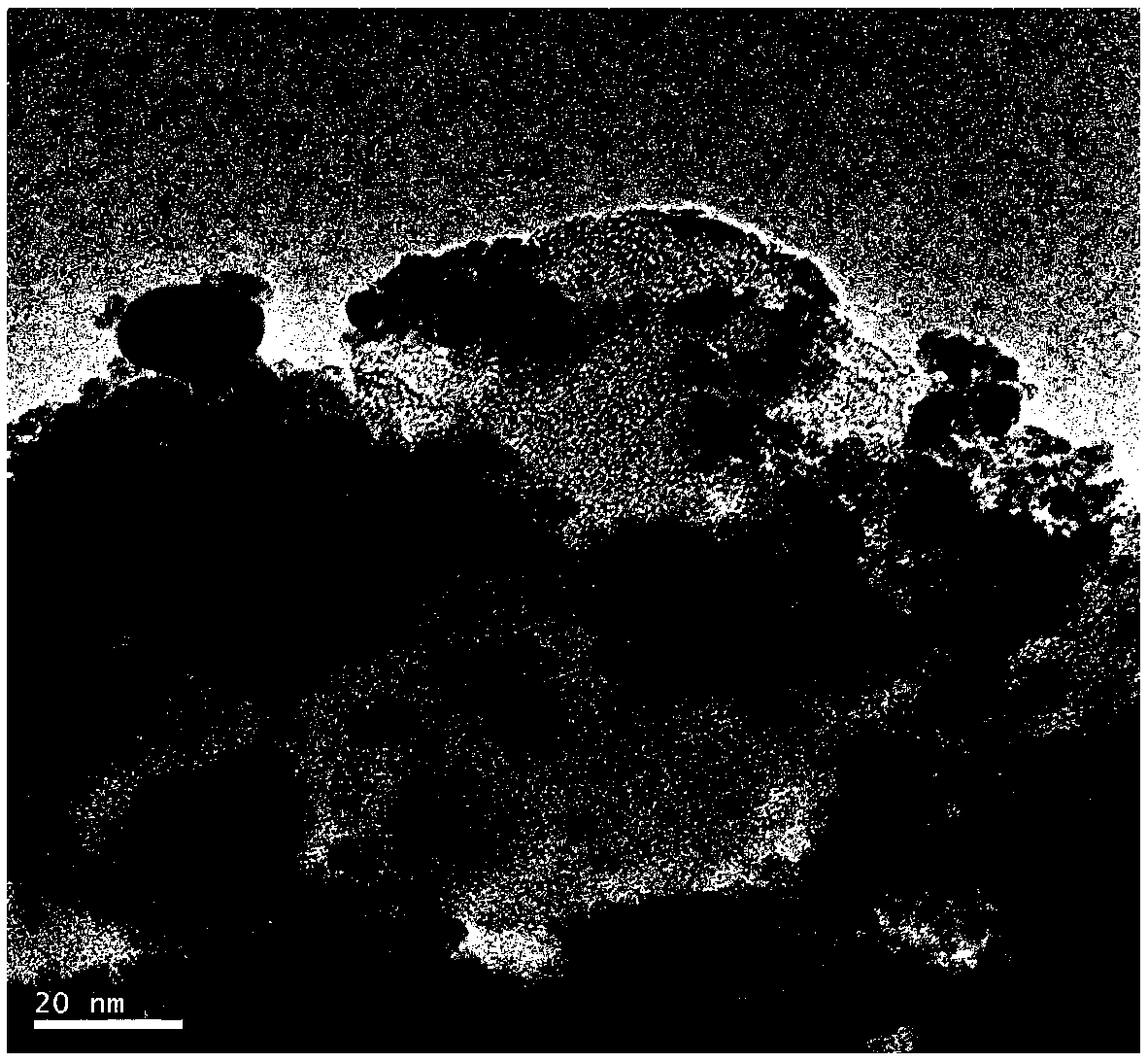

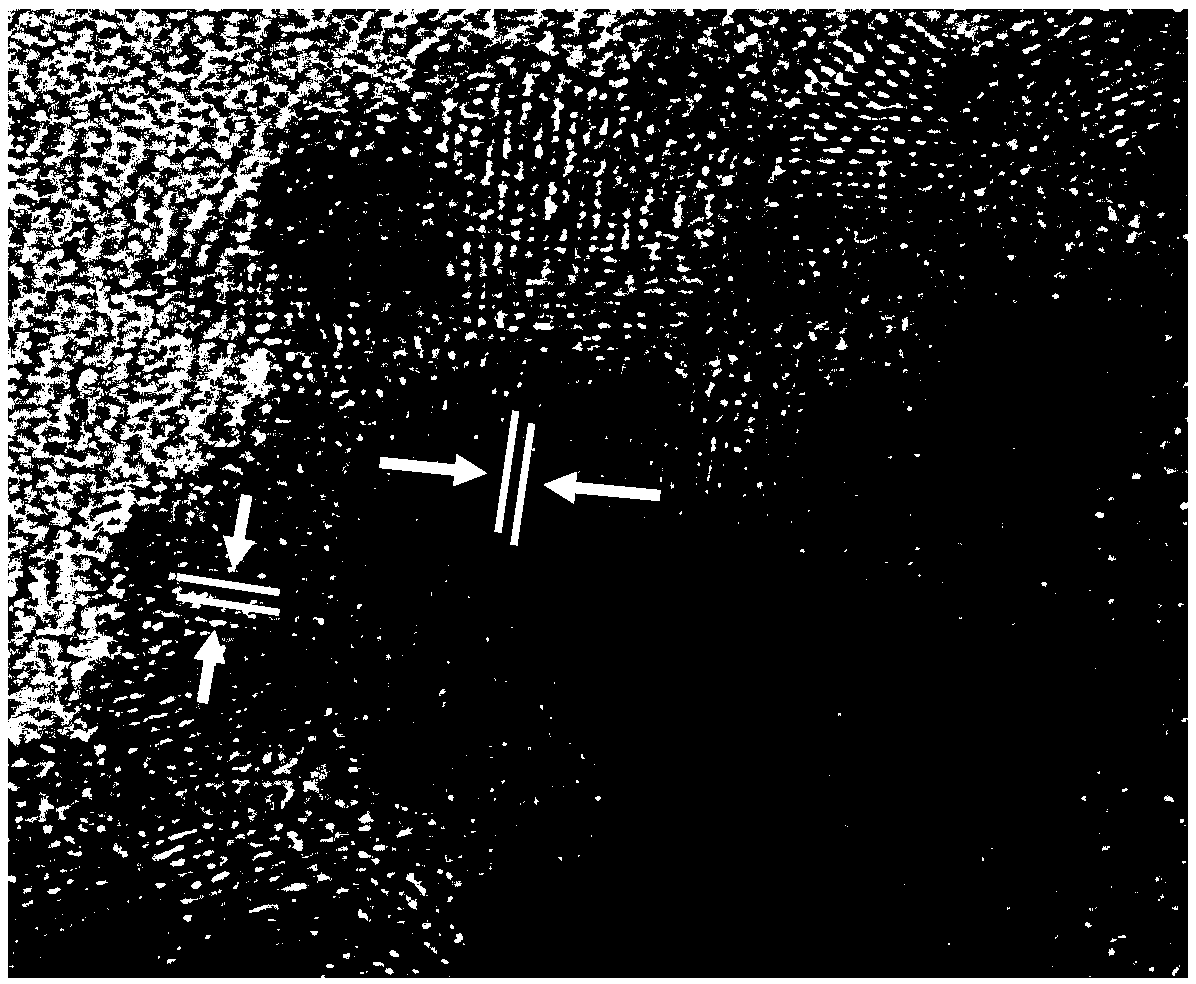

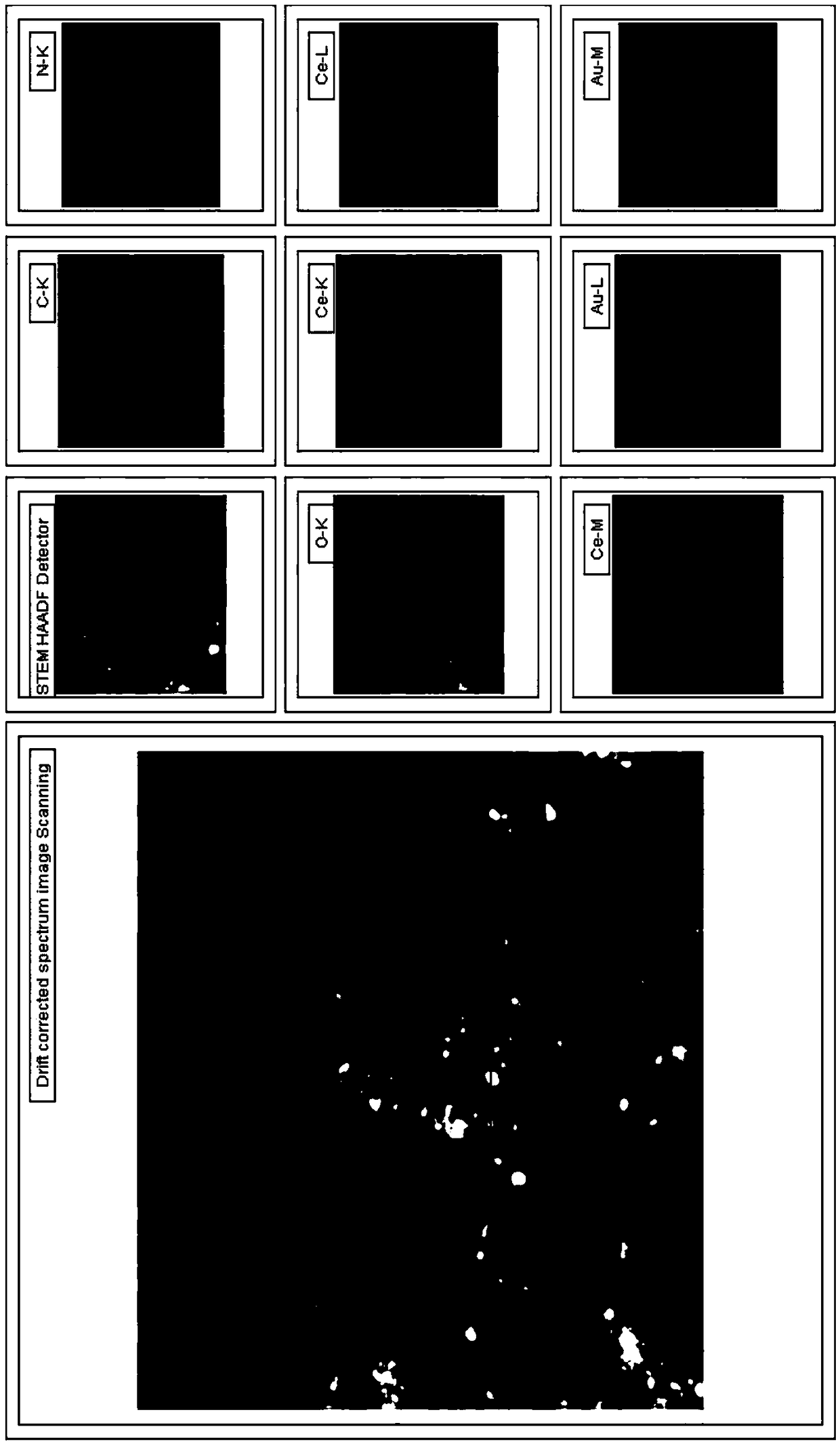

[0032] Example 1 Au / CeO 2 / g -C 3 N 4 Composite material preparation

[0033] Preparation of the first suspension: 0.76 mmol of g-C 3 N 4 The powder was added to 20ml deionized water, and ultrasonicated for 60 minutes to obtain the first suspension;

[0034] Cerium nitrate solution preparation: 0.24mmol of Ce(NO 3 ) 3 6H 2 O is dissolved in the deionized water of 100ml, obtains cerium nitrate solution;

[0035] Au / CeO 2 / g -C 3 N 4 Suspension preparation: under continuous ultrasonic conditions, add cerium nitrate solution to the first suspension to obtain the second suspension; adjust the pH value of the second suspension to 9.0 with NaOH (0.1mol / L), continue Sonicate for 24 hours, then add 4 ml of 7.0 mmol / L HAuCl to the second suspension 4 solution, after stirring for 6 hours with a magnetic stirrer, Au / CeO 2 / g -C 3 N 4 The third suspension;

[0036] Separation and drying: The third suspension is subjected to solid-liquid separation, the precipitate is washe...

Embodiment 2

[0037] Example 2 Au / CeO 2 / g -C 3 N 4 Composite material preparation

[0038] Preparation of the first suspension: 0.65 mmol of g-C 3 N 4 The powder was added to 20ml deionized water, and ultrasonicated for 60 minutes to obtain the first suspension;

[0039] Cerium nitrate solution preparation: 0.2mmol of Ce(NO 3 ) 3 6H 2 O is dissolved in the deionized water of 100ml, obtains cerium nitrate solution;

[0040] Au / CeO 2 / g -C 3 N 4 Suspension preparation: under continuous ultrasonic conditions, add cerium nitrate solution to the first suspension to obtain the second suspension; adjust the pH value of the second suspension to 8.8 with NaOH (0.1mol / L), continue Sonicate for 22 hours, then add 4 ml of 6.0 mmol / L HAuCl to the second suspension 4 solution, after stirring for 5 hours with a magnetic stirrer, Au / CeO 2 / g -C 3 N 4 The third suspension;

[0041] Separation and drying: The third suspension is subjected to solid-liquid separation, the precipitate is washed...

Embodiment 3

[0042] Example 3 Au / CeO 2 / g -C 3 N 4 Composite material preparation

[0043] Preparation of the first suspension: 0.87 mmol of g-C 3 N 4 The powder was added to 20ml deionized water, and ultrasonicated for 60 minutes to obtain the first suspension;

[0044] Cerium nitrate solution preparation: 0.28mmol of Ce(NO 3 ) 3 6H 2 O is dissolved in the deionized water of 100ml, obtains cerium nitrate solution;

[0045] Au / CeO 2 / g -C 3 N 4 Suspension preparation: under continuous ultrasonic conditions, add cerium nitrate solution to the first suspension to obtain the second suspension; adjust the pH value of the second suspension to 9.2 with NaOH (0.1mol / L), continue Sonicate for 25 hours, then add 4 ml of 8.0 mmol / L HAuCl to the second suspension 4 solution, after stirring for 7 hours with a magnetic stirrer, Au / CeO 2 / g -C 3 N 4 The third suspension;

[0046] Separation and drying: The third suspension is subjected to solid-liquid separation, the precipitate is washe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com