Bisphenol A disposable paper-based sensor and its preparation method and application

A sensor and paper-based technology, applied in the field of electrochemical detection, can solve the problems that bisphenol A cannot be measured multiple times, the surface of the working electrode is passivated, and it cannot be used to detect bisphenol A, so as to speed up the electron transport ability, Fast electrochemical detection, green and pollution-free materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

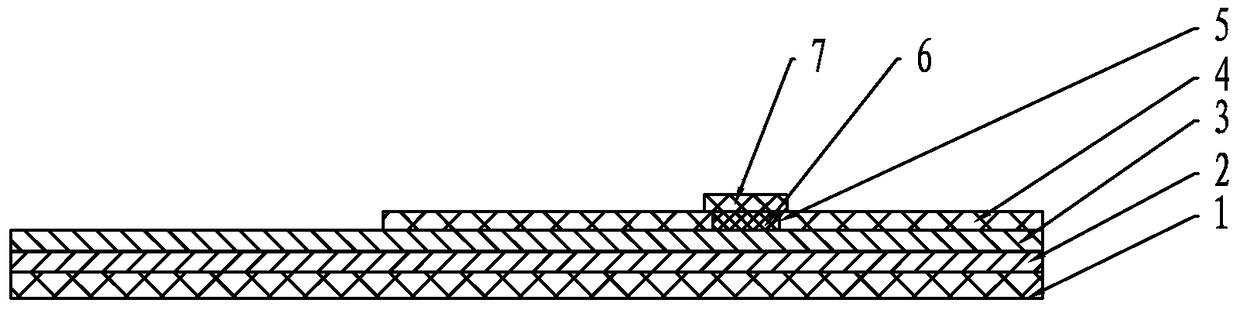

[0033] The preparation method of bisphenol A disposable paper-based sensor of the present invention comprises the following steps:

[0034] (1) Cut the coated coated paper to a certain size with scissors. The size of the coated coated paper is determined according to the model of the sputtering instrument, and cannot be larger than the maximum size that can be sputtered by the sputtering instrument;

[0035] (2) Place the coated coated paper on the sample stage of the high-vacuum ion sputtering instrument, first sputter a layer of nano-scale titanium film on the coated coated paper, and use titanium metal sheet as the sputtering target. The distance from the sample stage is 5-9cm, and the sputtering vacuum is not greater than 2×10 -3 mbar, the sputtering current is 80-120mA, and the sputtering time is 50-150s; then, a layer of nanoscale gold film is sputtered on the titanium film, and the gold sheet is used as the sputtering target, and the distance between the target and the ...

Embodiment 1

[0040] A preparation method of bisphenol A disposable paper-based sensor, comprising the following steps:

[0041] (1) Cut the coated coated paper into a certain size with scissors, and the size of the coated coated paper is determined according to the model of the sputtering machine;

[0042] (2) Place the coated coated paper on the sample stage of the high-vacuum ion sputtering instrument, first sputter a layer of nano-scale titanium film on the coated coated paper, and use titanium metal sheet as the sputtering target. The distance from the sample stage is 5cm, and the sputtering vacuum is not greater than 2×10 -3 mbar, the sputtering current is 80mA, and the sputtering time is 50s; then, a layer of nanoscale gold film is sputtered on the titanium film, and the gold sheet is used as the sputtering target, and the distance between the target and the sample stage is 5cm. Sputtering vacuum degree is not greater than 2×10 -3 mbar, the sputtering current is 15mA, and the sputter...

Embodiment 2

[0047] A preparation method of bisphenol A disposable paper-based sensor, comprising the following steps:

[0048] (1) Cut the coated coated paper into a certain size with scissors, and the size of the coated coated paper is determined according to the model of the sputtering machine;

[0049] (2) Place the coated coated paper on the sample stage of the high-vacuum ion sputtering instrument, first sputter a layer of nano-scale titanium film on the coated coated paper, and use titanium metal sheet as the sputtering target. The distance from the sample stage is 9cm, and the sputtering vacuum is not greater than 2×10 -3 mbar, the sputtering current is 100mA, and the sputtering time is 100s; then, a layer of nanoscale gold film is sputtered on the titanium film, and the gold sheet is used as the sputtering target, and the distance between the target and the sample stage is 9cm. Sputtering vacuum degree is not greater than 2×10 -3 mbar, the sputtering current is 34mA, and the spu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com