A detection method and device for coking coalization behavior correlation

A technology of detection device and detection method, applied in the direction of measurement device, fuel oil test, material inspection product, etc., can solve the problems of high labor intensity, cumbersome operation, measurement and data recording cannot be performed synchronously, etc., and achieves a high degree of automation and equipment operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

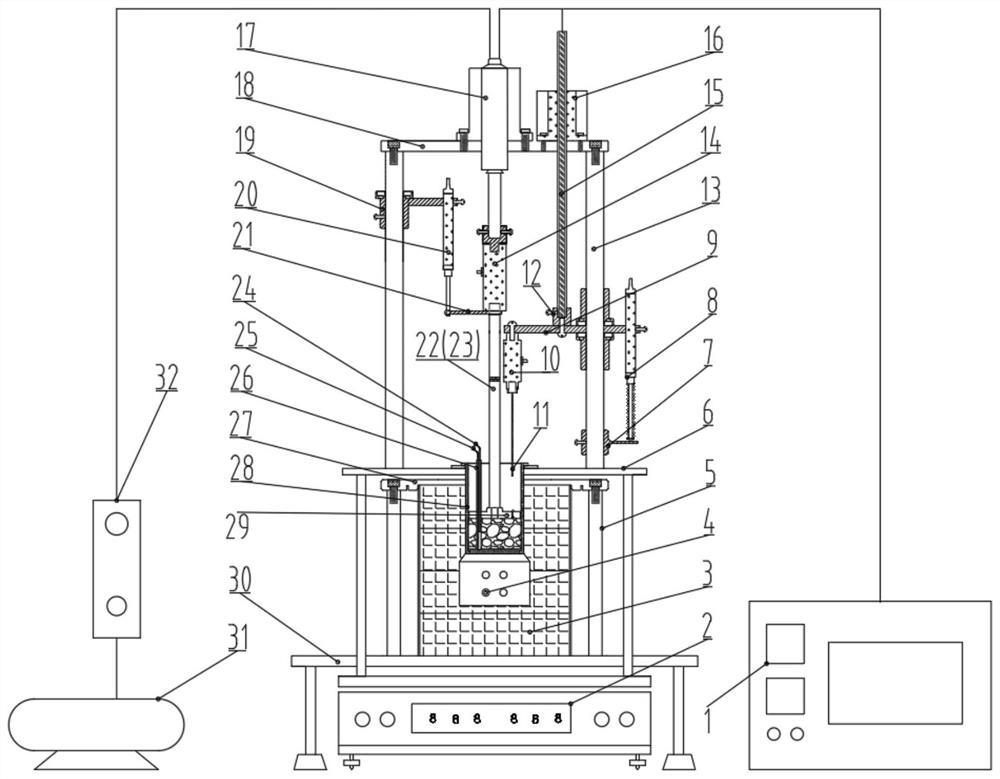

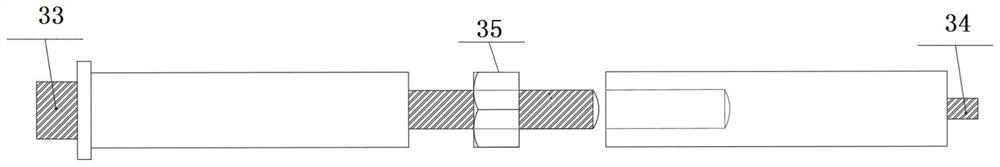

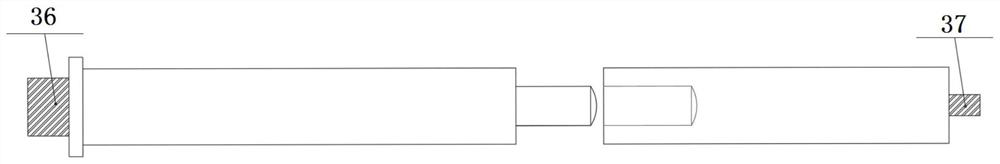

[0040] Such as Figure 1-3 As shown, a coking coal-correlated behavior correlation device, including: control cabinet (1), electronic balance (2), furnace body (3), heating body (4), thermocouple (24) and (25) , Coal Cup (28), Load Sensor (14), Displacement Sensor (20), Probe Displacement Sensor (8), Probe Pressure Sensor (10), Cylinder (17), Regulator (32), Air Compressor (31) and support and fixing devices, including 1 # guide (22), 2 # guide rod (23), connecting rod (21), pressure disc (29), stepping motor (16), a screw (15 ); Stepping motor (16) and cylinder (17) are fixed to the top fixation plate (18), the push force of the stepping motor (16) is driven by a screw (15) to the probe push plate (9), a screw (15), the probe displacement sensor (8) and the probe pressure sensor (10) are fixed to the probe push plate (9), the probe push plate (9) is fixed to the sleeve of the lifting slider (13) Upper, formulating the glio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com