Stabilizer for alkaline etching regenerated electrolytic copper and electrolyte solution

A technology of stabilizer and electrolytic copper, which is applied in the direction of improving process efficiency, photographic technology, instruments, etc., can solve problems such as fragility, copper product phase difference, and affect the price, so as to achieve the effect of improving stability and improving copper product phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, the content (concentration) of each component of the electrolyte in the electrolytic tank in the alkaline etching electrolytic recovery system is as follows: the content of chloride ions is 176 g / L, the concentration of copper ions is 22.5 g / L, and the pH of the electrolyte is 8.9.

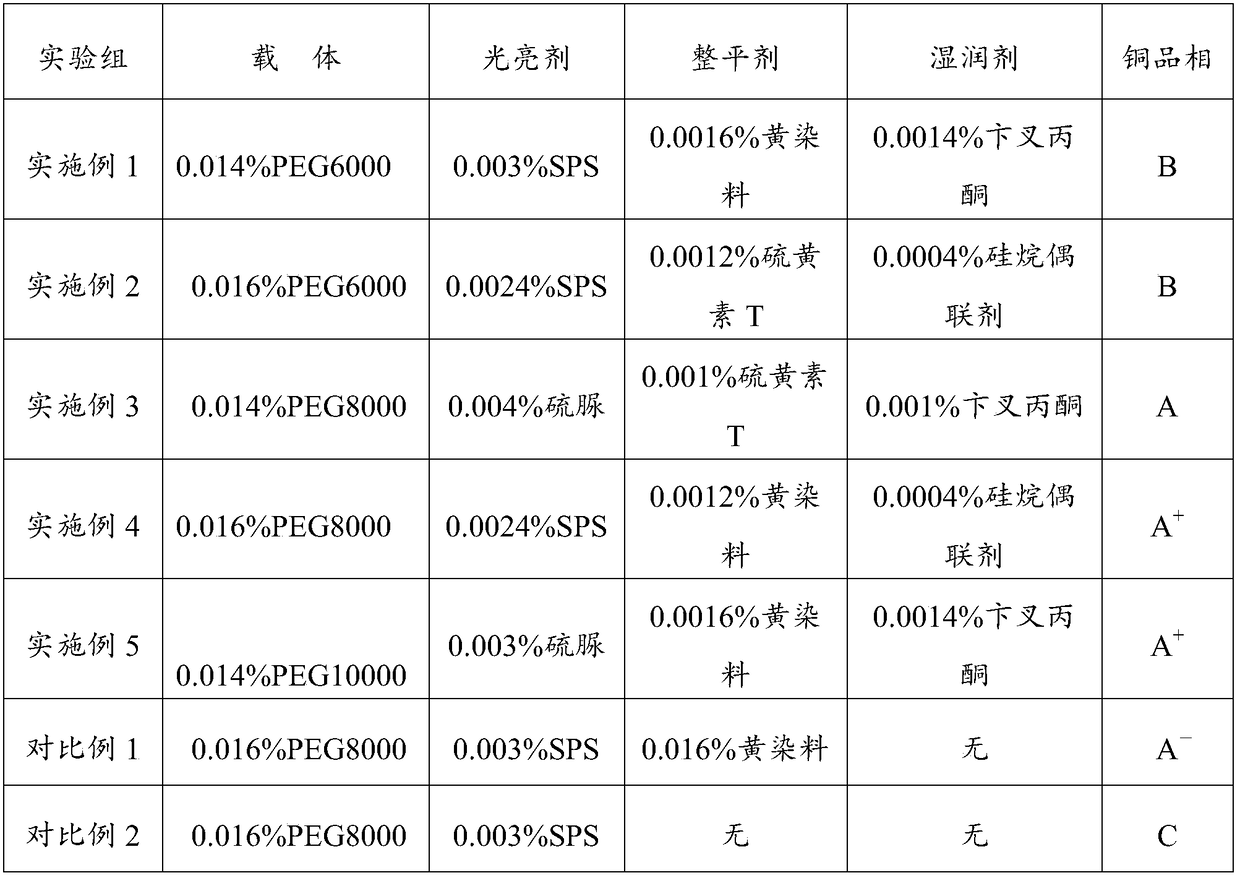

[0036] Add 0.1% ammonium chloride containing the stabilizer to the electrolytic solution, which contains 0.02% stabilizer. The contents of each component of the stabilizer are shown in Table 1. After circulating for half an hour, electrolytic copper is carried out according to the following method operate.

[0037] Turn on the electrolysis equipment, set the current of the rectifier to 1000A for electrolysis, control the temperature of the electrolysis tank at 35°C, increase the current by 200A / h after 4 hours of electrolysis, and stop increasing the current after it reaches 1800A. During this period, adjust the flowmeter to control the alkali The replenishment amount of...

Embodiment 2

[0039] In this embodiment, the content (concentration) of each component of the electrolyte in the electrolytic tank in the alkaline etching electrolytic recovery system is as follows: the content of chloride ions is 176 g / L, the concentration of copper ions is 22.5 g / L, and the pH of the electrolyte is 8.9.

[0040] In this electrolytic solution, adding mass percent is the ammonium chloride that contains this stabilizer of 0.1%, wherein contains 0.02% stabilizer, and the content of each component of stabilizer is shown in Table 1, circulates after half an hour according to the method in embodiment 1 Method for electrolytic copper operation. And the phase observation results of the single copper layer obtained in this embodiment are recorded in Table 1.

Embodiment 3

[0042] In this embodiment, the content (concentration) of each component of the electrolyte in the electrolytic tank in the alkaline etching electrolytic recovery system is as follows: the content of chloride ions is 176 g / L, the concentration of copper ions is 22.5 g / L, and the pH of the electrolyte is 8.9.

[0043] In this electrolytic solution, adding mass percent is the ammonium chloride that contains this stabilizer of 0.1%, wherein contains 0.02% stabilizer, and the content of each component of stabilizer is shown in Table 1, circulates after half an hour according to the method in embodiment 1 Method for electrolytic copper operation. And the phase observation results of the single copper layer obtained in this embodiment are recorded in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com