Preparation method of sample for testing metallographic structure of vanadium-based alloys

A metallographic structure and sample preparation technology, which is applied in the field of sample preparation for vanadium-based alloy metallographic structure inspection, can solve the problem of affecting the display effect of vanadium-based alloy sample inspection and analysis, affecting the effect of grinding and polishing treatment, and affecting The quality of sample preparation of vanadium-based alloys can solve the problems of easy slag falling and sand embedding, good display effect, reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

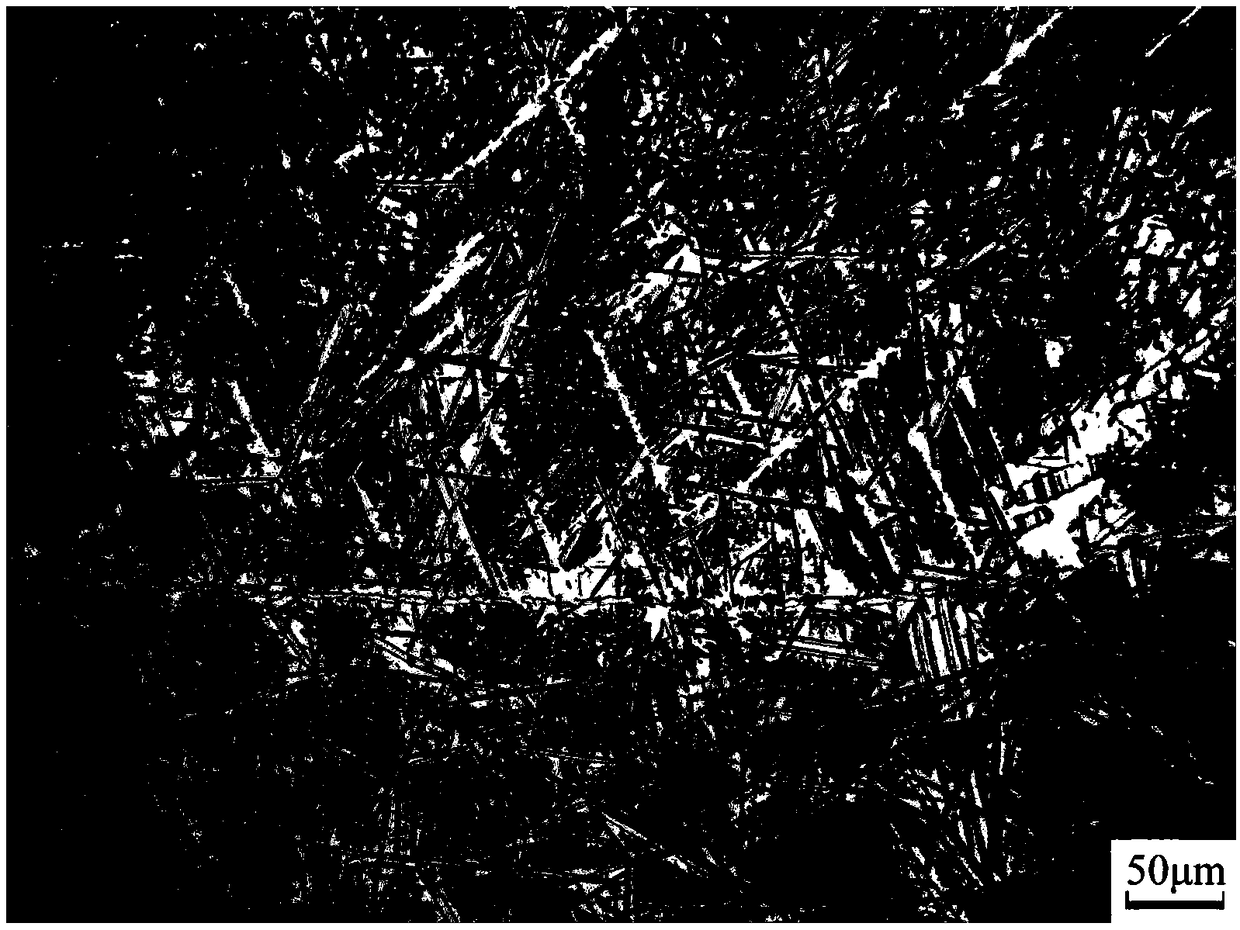

[0045] The present invention carries out sample preparation on the basis of the metallographic examination and analysis of VCr2 alloy, and the present invention comprises following process step:

[0046] Step 1. Cut and sample the VCr2 alloy material by wire electric discharge cutting, and the sample size is about 20mm×15mm;

[0047] Step 2. Thermally mount the sample on the resin matrix, and the cured hardness of the resin matrix after thermal mounting is required to be kept at about 48HRC;

[0048] Step 3. Polish the sample on the resin matrix according to the following procedure:

[0049] ①. Use 120# water sandpaper to grind the sample in a single direction, lubricate with water during the grinding process, and the grinding depth is about 0.5mm;

[0050] ②. Rotate and adjust the sample by about 90° relative to the polishing direction of process ①, and use 400# metallographic sandpaper to grind the sample in a single direction, and the thickness of the grinding removal is a...

Embodiment 2

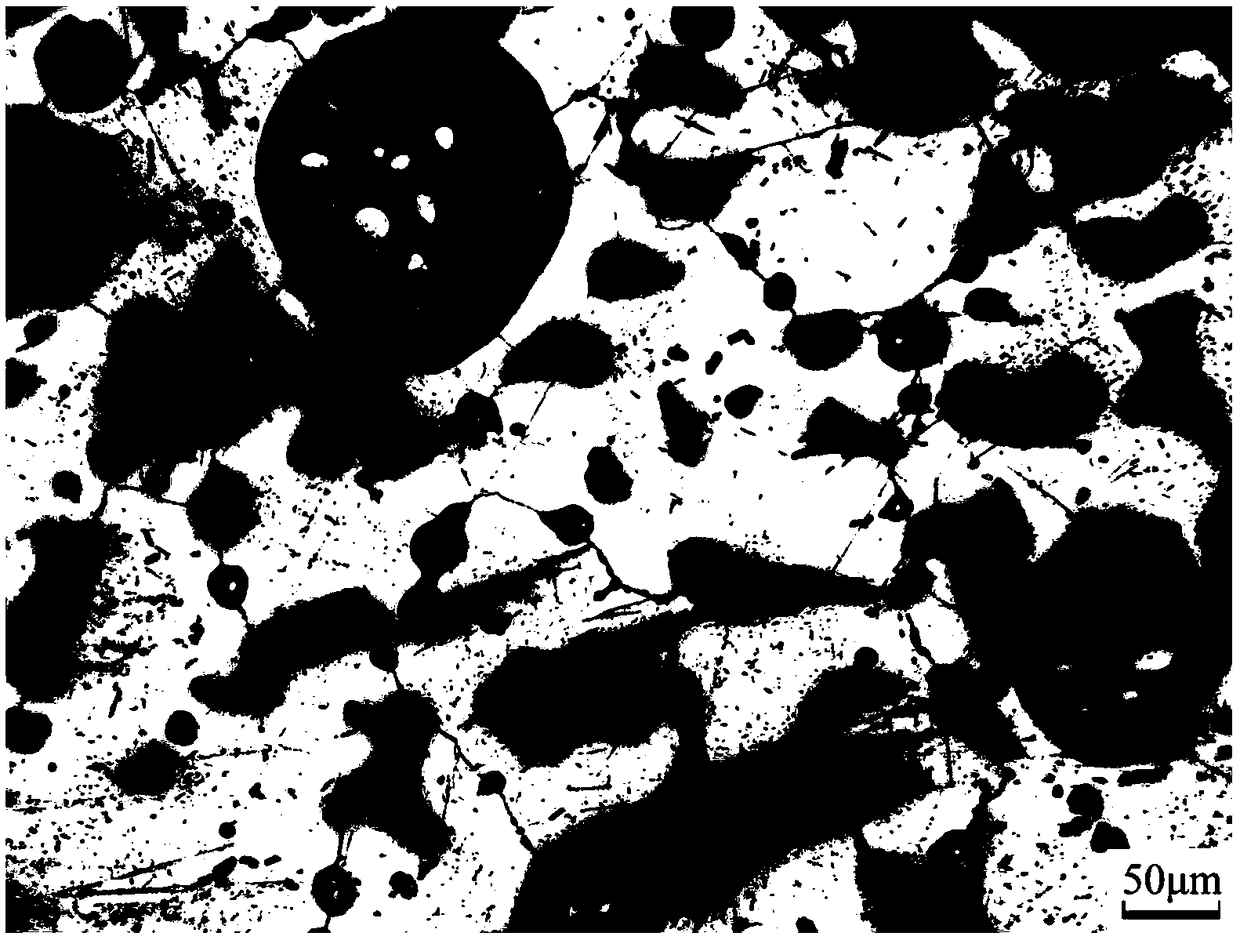

[0064] The present invention carries out sample preparation on the basis of the metallographic structure inspection analysis of VCrTi1 alloy, and the present invention comprises following processing steps:

[0065] Step 1. Cut and sample the VCrTi1 alloy material by wire electric discharge cutting, and the sample size is about 20mm×15mm;

[0066] Step 2. Thermally mount the sample on the resin matrix, and the cured hardness of the resin matrix after thermal mounting is required to be maintained at about 50HRC;

[0067] Step 3. Polish the sample on the resin matrix according to the following procedure:

[0068] ①. Use 120# water sandpaper to grind the sample in one direction, lubricate with water during the grinding process, and the grinding depth is about 0.4mm;

[0069] ②. Rotate and adjust the sample by about 80° relative to the polishing direction of process ①, and use 400# metallographic sandpaper to grind the sample in a single direction, and the thickness of the grindin...

Embodiment 3

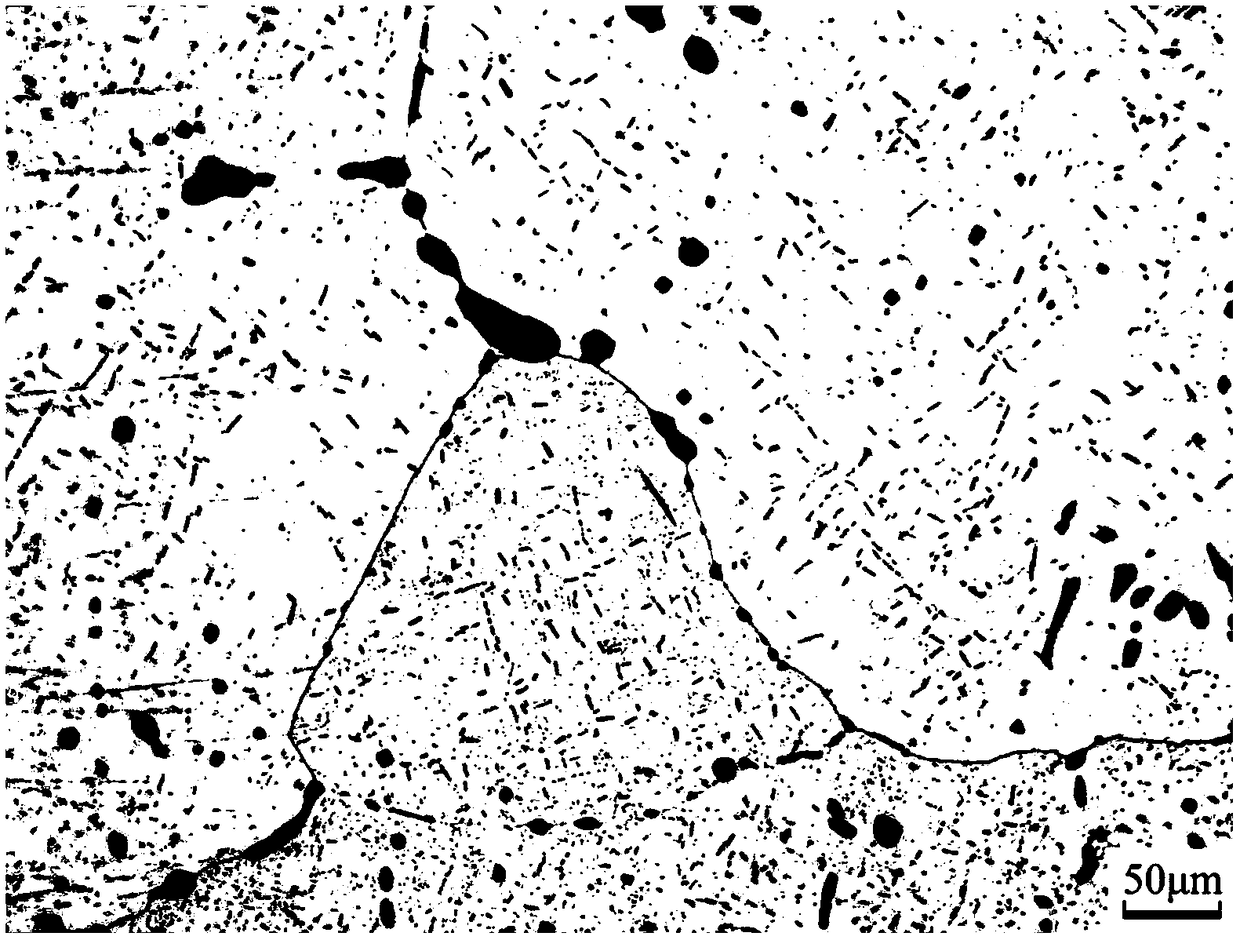

[0083] The present invention carries out sample preparation on the basis of the metallographic structure inspection analysis of VCrTi4 alloy, and the present invention comprises following process steps:

[0084] Step 1. Cut and sample the VCrTi4 alloy material by wire electric discharge cutting, and the sample size is about 20mm×15mm;

[0085] Step 2. Thermally mount the sample on the resin matrix, and the cured hardness of the resin matrix after thermal mounting is required to be maintained at about 52HRC;

[0086] Step 3. Polish the sample on the resin matrix according to the following procedure:

[0087] ①. Use 120# water sandpaper to grind the sample in a single direction, lubricate with water during the grinding process, and the grinding depth is about 0.3mm;

[0088] ②. Rotate and adjust the sample by about 45° relative to the polishing direction of process ①, and use 400# metallographic sandpaper to grind the sample in a single direction, and the thickness of the grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com