Lithium ion battery slurry and assessment method of stability thereof

A lithium-ion battery and stability technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as inability to evaluate lithium-ion batteries, and achieve the effect of ensuring accuracy, reasonable stability, and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

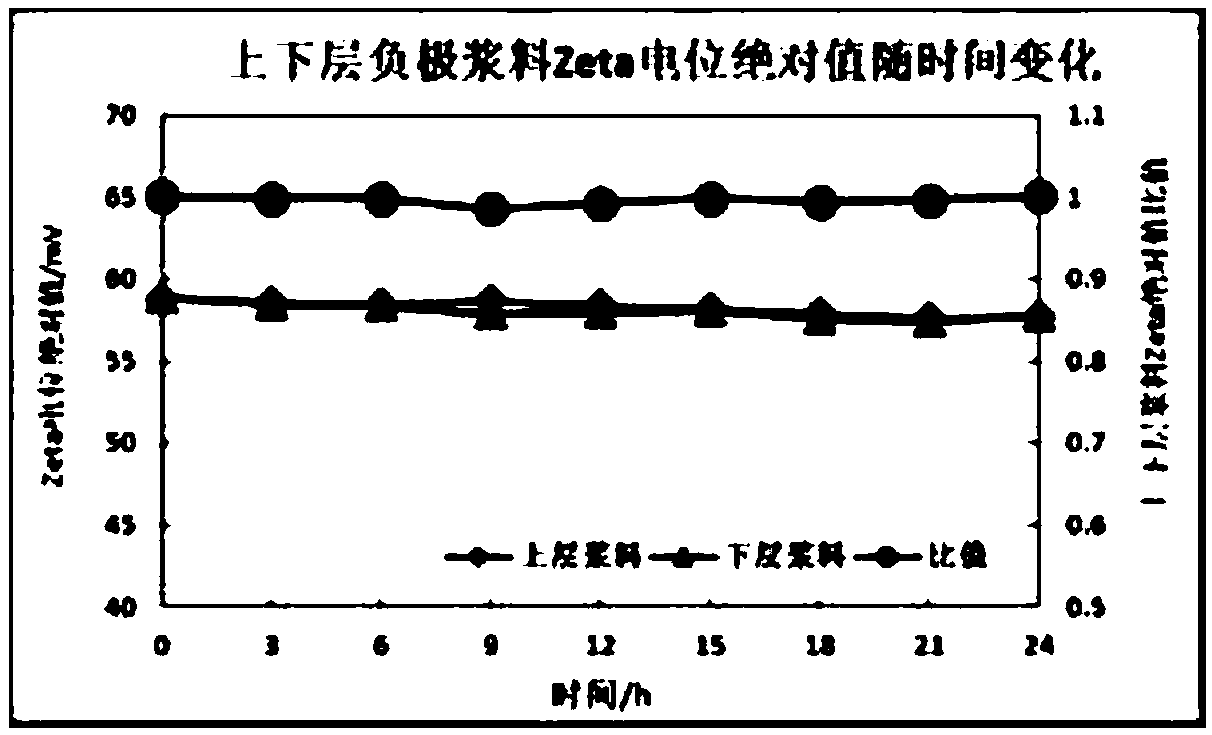

Embodiment 1

[0035] First weigh artificial graphite, acetylene black, CMC, and SBR according to the weight percentage of 93%: 2.5%: 1.0%: 3.5%, and then weigh the solvent deionized water according to the proportion of the glue solid content of 1.2%, and the stirring speed is 40 rpm Dispersion speed of 35 rpm, 3h to get a uniform and transparent glue; then add conductive agent acetylene black according to the stirring speed of 35 rpm, dispersion speed of 35 rpm, run for 1h; then add artificial graphite, according to the stirring speed of 35 RPM, dispersion speed 30 RPM, run for 4h; finally add SBR, according to stirring speed 35 RPM, disperse speed 40 RPM, run for 2h to get negative electrode slurry. The slurry viscosity is 4100mPa.s, and the solid content is 47%. After stirring, 0h, 3h, 6h, 9h, 12h, 15h, 18h, 21h, 24h, take out 150mL slurry from the upper and lower layers respectively, put them into numbered beakers, keep them sealed, and let them stand for 2h.

[0036] Ultrasonic ultraso...

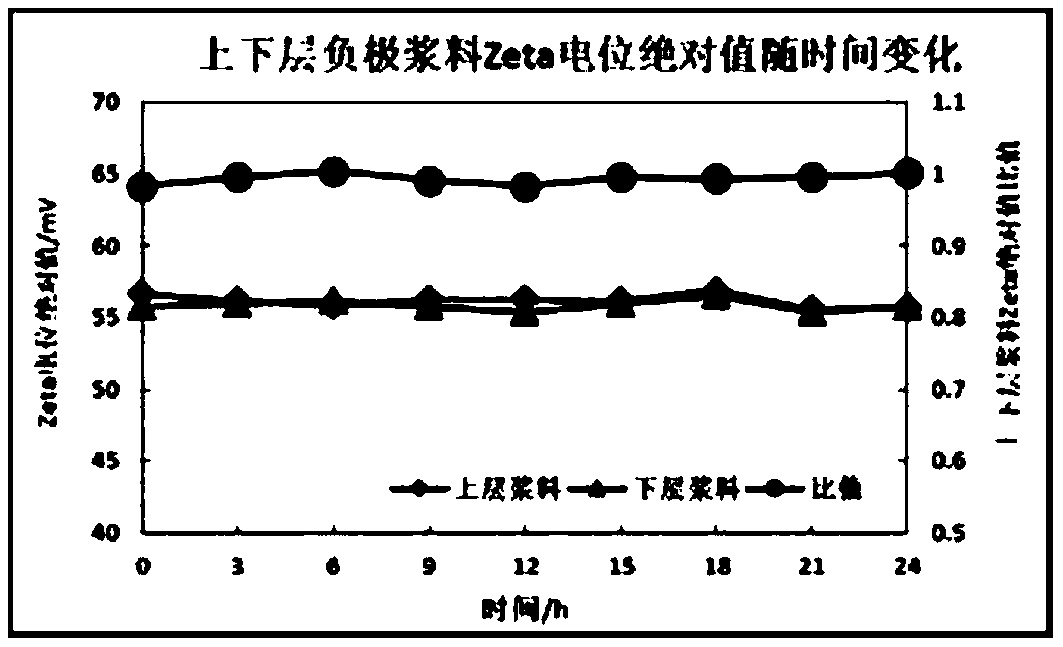

Embodiment 2

[0044] First weigh artificial mixed natural graphite, acetylene black, CMC, SBR according to the weight percentage of 93%: 2.5%: 1.0%: 3.5%, and then weigh the solvent deionized water according to the proportion of the glue solid content of 1.2%, stirring speed 40 rpm, dispersion speed 35 rpm, 3h to get a uniform and transparent glue; then add conductive agent acetylene black according to stirring speed 35 rpm, dispersion speed 35 rpm, run for 1h; then add artificial graphite, stir according to The speed is 35 rpm, the dispersion speed is 30 rpm, and the operation is 4 hours; finally, SBR is added, and the stirring speed is 35 rpm, and the dispersion speed is 40 rpm, and the operation is 2 hours to obtain the negative electrode slurry. The slurry viscosity is 4200mPa.s, and the solid content is 46.5%. After stirring, 0h, 3h, 6h, 9h, 12h, 15h, 18h, 21h, 24h, take out 150mL slurry from the upper and lower layers respectively, put them into numbered beakers, keep them sealed, and...

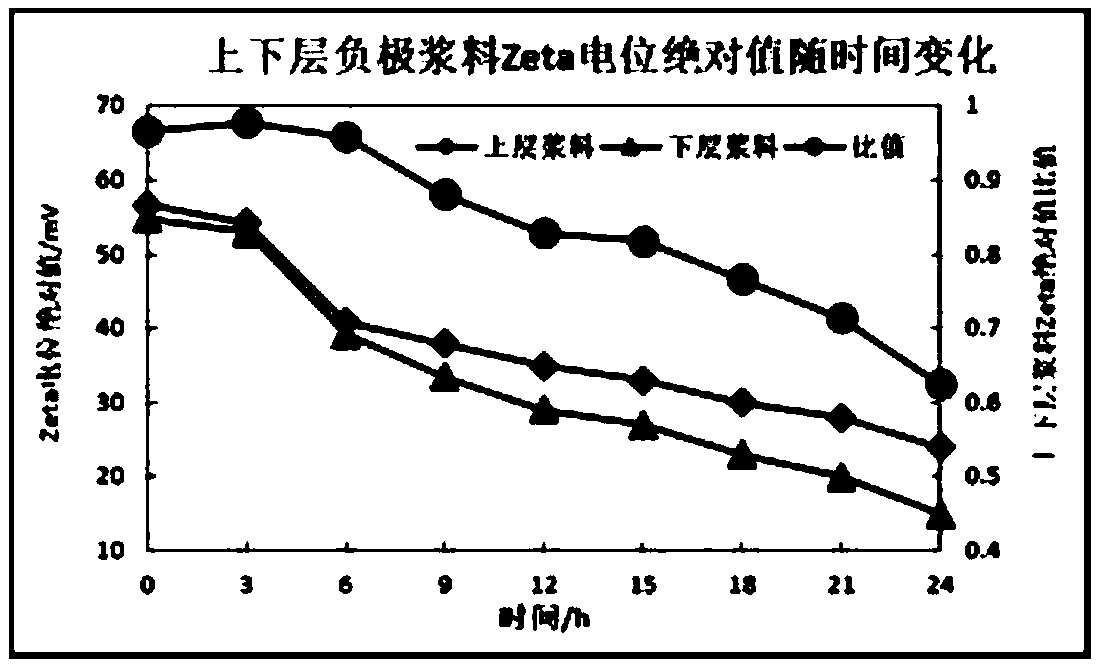

Embodiment 3

[0050] First weigh nickel-cobalt-manganese (NCM111), SP-Li, PVDF according to the percentage by weight of 95%: 2.7%: 2.3%, and then take the solvent NMP according to the ratio of the glue solid content of 6.5%, stirring speed 40 rpm, The dispersion speed is 35 rpm, 3h to get a uniform and transparent glue; then add the conductive agent acetylene black according to the stirring speed of 35 rpm, the dispersion speed is 35 rpm, and run for 1h; then add nickel cobalt manganese (NCM111), according to the stirring The speed is 35 rpm, the dispersion speed is 30 rpm, and the positive electrode slurry is obtained by running for 4 hours. The slurry viscosity is 7500mPa.s, and the solid content is 68.2%. After stirring, 0h, 3h, 6h, 9h, 12h, 15h, 18h, 21h, 24h, take out 150mL slurry from the upper and lower layers respectively, put them into numbered beakers, keep them sealed, and let them stand for 2h.

[0051] Ultrasonic ultrasonic dispersion for 40s, the Zeta potential of the slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com