Interstage connecting structure with high damping and impact-resistant function

A connecting structure and impact-resistant technology, which is applied in transportation and packaging, space navigation equipment, space navigation aircraft, etc., can solve the problems of system complexity, lower reliability, sacrifice of structural rigidity, etc., and achieve strong environmental adaptability and light weight. Small weight, the effect of meeting the requirements of connection stiffness and vibration damping and buffering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

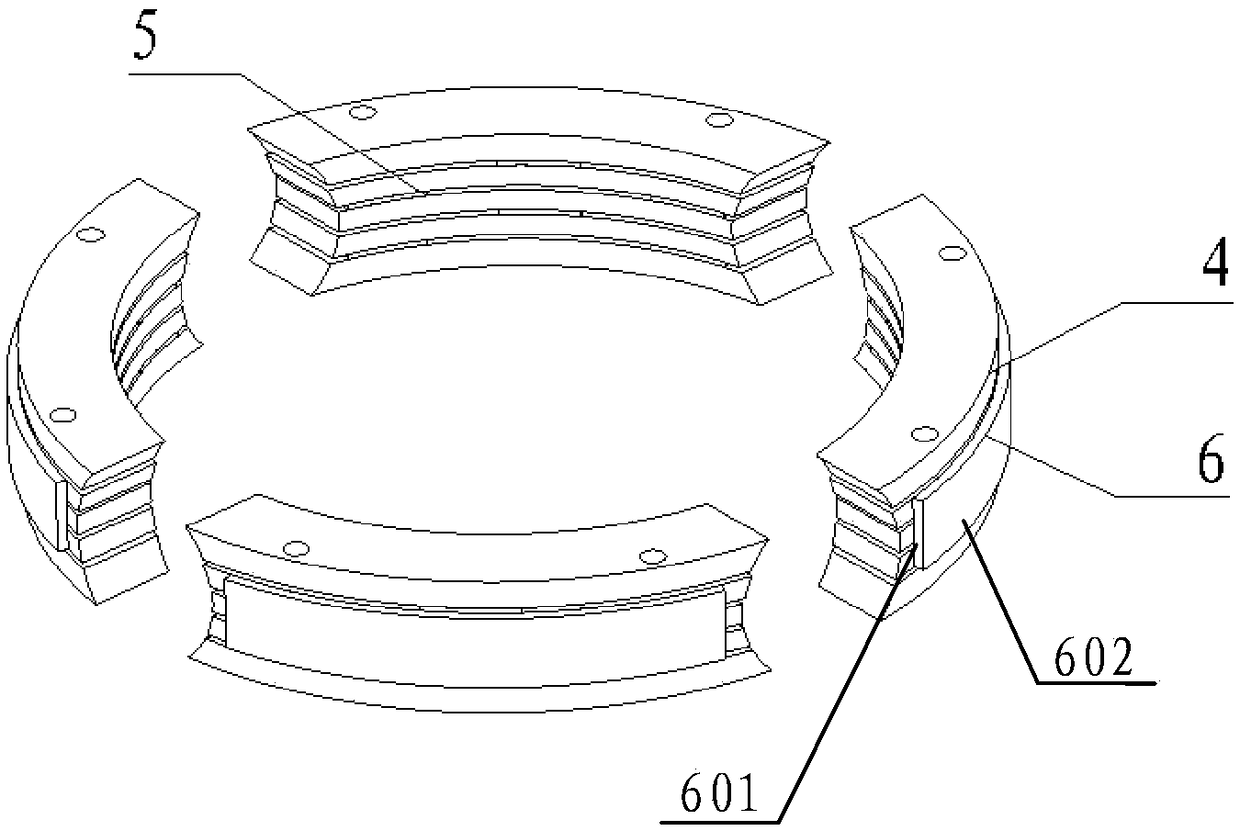

[0016] An interstage connection structure with both high damping and shock resistance functions. Its vibration damping and buffering principle is to use metal sheets with different thicknesses to stack to form a periodic structure. By changing the load transmission path, the transmission of shock stress waves can be effectively attenuated. The gap suppresses the vibration energy transfer in the target frequency band.

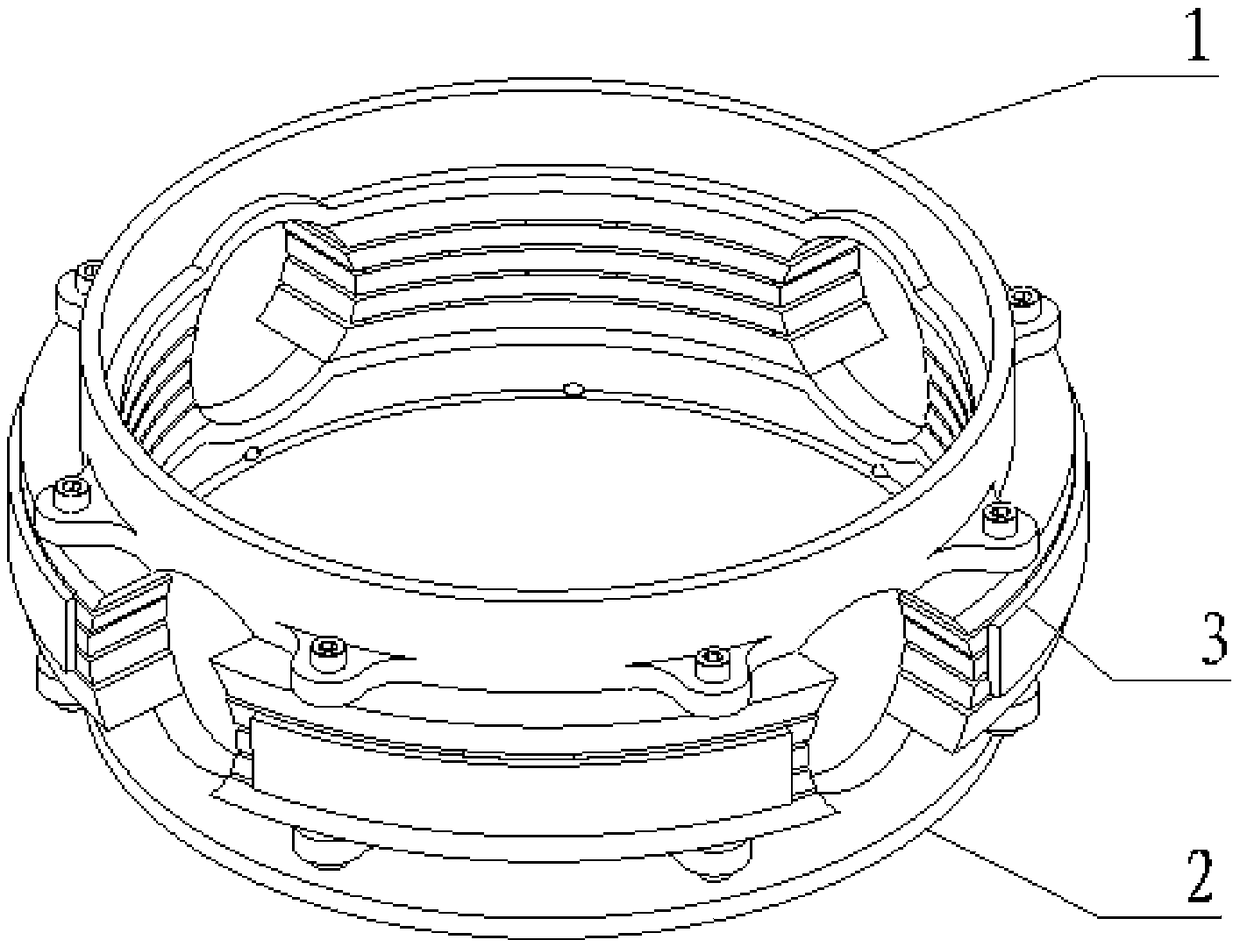

[0017] Such as figure 1 , figure 2 As shown, the interstage connection structure 3 with both high damping and impact resistance functions is installed between the upper cabin section 1 and the lower cabin section 2 through bolt connection in actual use; the interstage connection structure with both high damping and impact resistance functions The connecting structure 3 includes a primary connecting piece 4 , a secondary connecting piece 5 and a constr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com