Preparation method of antibacterial high-strength polyethylene fibers

A technology of high-strength polyethylene and a manufacturing method, which is applied in the field of fiber manufacturing, can solve the problem that high-strength and high-modulus polyethylene fibers do not have antibacterial effect, etc., and achieve the effect of good antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

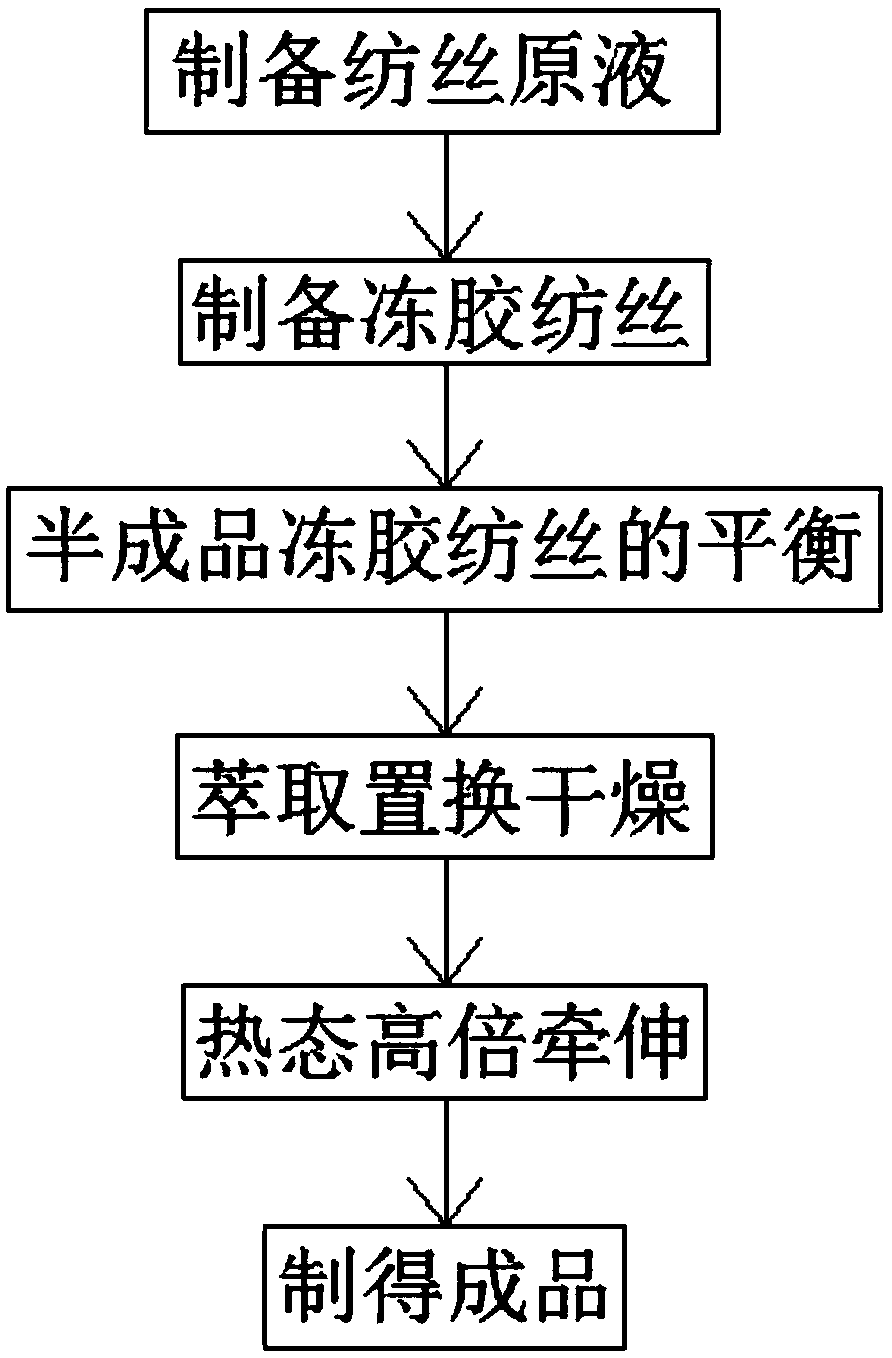

Method used

Image

Examples

Embodiment 1

[0044] Step (1) Prepare spinning dope: heat 330g of white oil to 50°C, add 30g of ultra-high molecular weight polyethylene, fully disperse and emulsify in a high-speed emulsifier to form a mixture of ultra-high molecular weight polyethylene and white oil; Put 0.396g of nano-silver powder antibacterial additive into the above mixture, and fully emulsify it again in a high-speed emulsifier; put the obtained mixture material into a reactor at 100°C and heat it up and stir for 2 hours to prepare the swelling material to obtain spinning dope;

[0045] Step (2) Preparation of jelly spinning: transfer the prepared spinning stock solution to the twin-screw spinning machine, extrude, melt, stir, and control the temperature of the spinning stock solution at 250°C, and pass through the spinning assembly The viscous filaments are ejected and cooled by circulating cooling water to form gel spinning;

[0046] Step (3) Balance of semi-finished jelly spinning: store the formed jelly spinning...

Embodiment 2

[0051] Step (1) Preparation of spinning dope: heat 330g of white oil to 55°C, add it to 30g of ultra-high molecular weight polyethylene, and fully disperse and emulsify it in a high-speed emulsifier to form a mixture of ultra-high molecular weight polyethylene and white oil 0.693g of nano-silver powder antibacterial additives are dropped into the above-mentioned mixture, and fully emulsified in a high-speed emulsifier again; the obtained mixture is put into a 110°C reactor and heated and stirred for 2.5 hours, and the swelling material is prepared to obtain spinning dope;

[0052] Step (2) Preparation of jelly spinning: transfer the prepared spinning stock solution to the twin-screw spinning machine, extrude, melt, stir, and control the temperature of the spinning stock solution at 275 ° C, and pass through the spinning assembly The viscous filaments are ejected and cooled by circulating cooling water to form gel spinning;

[0053] Step (3) Balance of semi-finished jelly spin...

Embodiment 3

[0058] Step (1) Preparation of spinning dope: heat 330g of white oil to 60°C, add it to 30g of ultra-high molecular weight polyethylene, and fully disperse and emulsify it in a high-speed emulsifier to form a mixture of ultra-high molecular weight polyethylene and white oil ; put 0.99g of nano-silver powder antibacterial additive into the above mixture, and fully emulsify it again in a high-speed emulsifier; put the obtained mixture in a reactor at 120°C for 3 hours and heat up and stir for 3 hours to prepare the swelling material. Obtain spinning dope;

[0059] Step (2) Preparation of jelly spinning: transfer the prepared spinning stock solution to the twin-screw spinning machine, extrude, melt, stir, and control the temperature of the spinning stock solution at 300°C, pass through the spinning assembly The viscous filaments are ejected and cooled by circulating cooling water to form gel spinning;

[0060] Step (3) Balance of semi-finished jelly spinning: store the formed je...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com